Wave maker for generating simulated waves

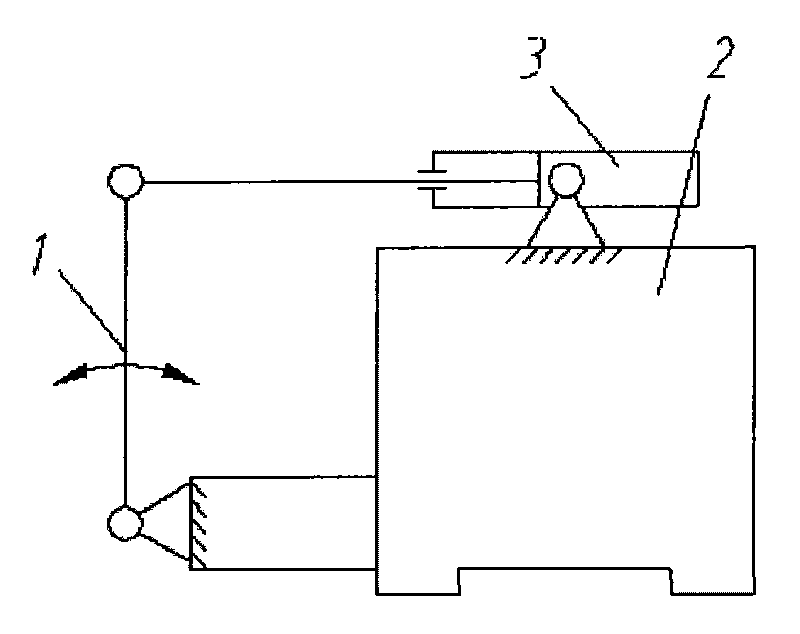

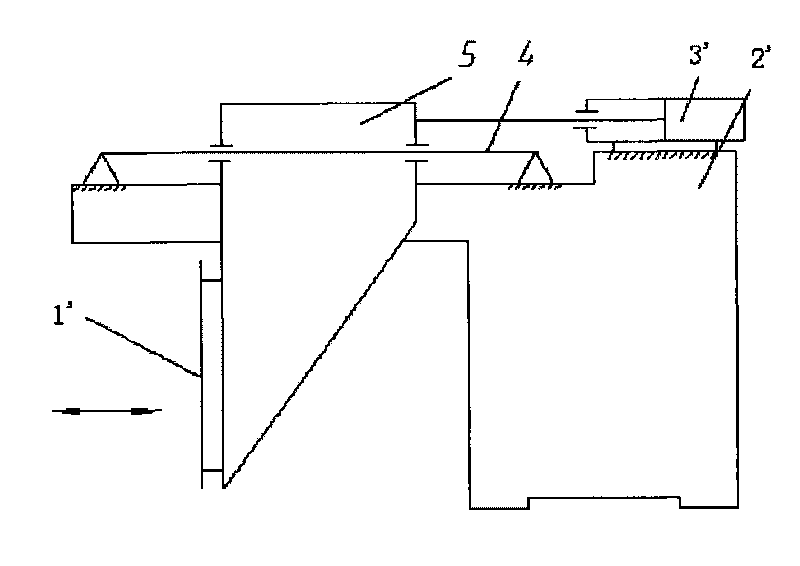

A wave generator and base technology, which is applied in the field of port and offshore engineering experimental research, can solve problems such as the inability to meet the complexity and diversity requirements of experimental research, and the single movement form of the wave generator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

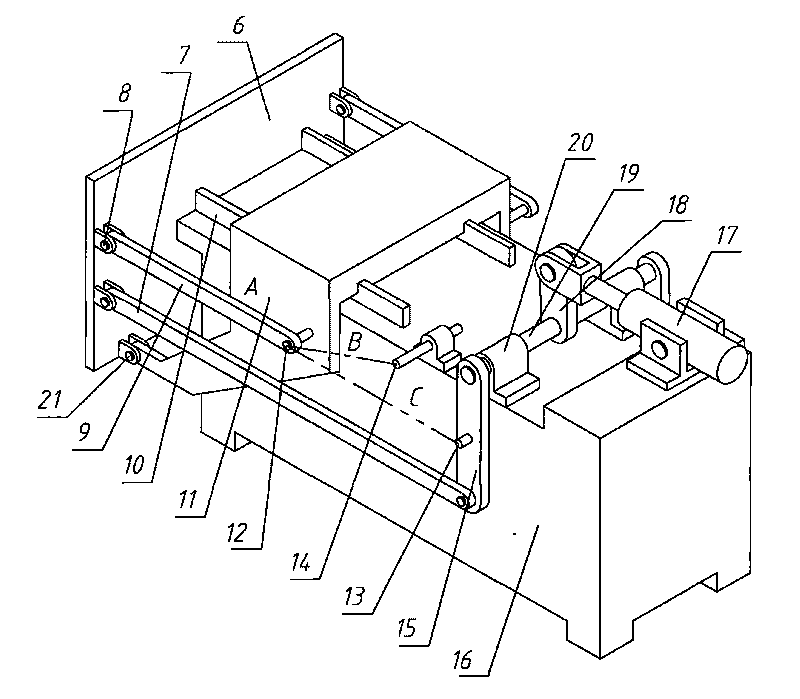

[0020] The specific structure of the wave maker for generating simulated waves of the present invention will be described below with reference to the accompanying drawings.

[0021] Such as image 3 As shown, the wave maker of the present invention includes: a machine base 16, a driving device 17 for driving the movement of the wave-making plate, a linear guide rail 10 arranged on the machine base 16, and a linear guide rail 10 which is arranged on the linear guide rail 10 and can move along the linear guide rail 10. The moving carriage 11, the wave pushing plate 6 arranged at the front end of the machine base 16, and the push rods 7 symmetrically arranged on both sides of the machine base 16 and pushing the wave making plate 6 to move under the action of the driving device 17. In addition, the wave maker of the present invention also includes a first swing arm 18 whose upper end is hinged to the output end of the driving device 17, a transverse shaft 19 perpendicular to and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com