Automatic alignment lift valve

A lift valve, valve plate technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problem that the valve plate and the dust collector door are difficult to achieve tightness, and the valve plate cannot automatically find the round hole very well, etc. problem, to achieve good sealing and increase the effect of the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

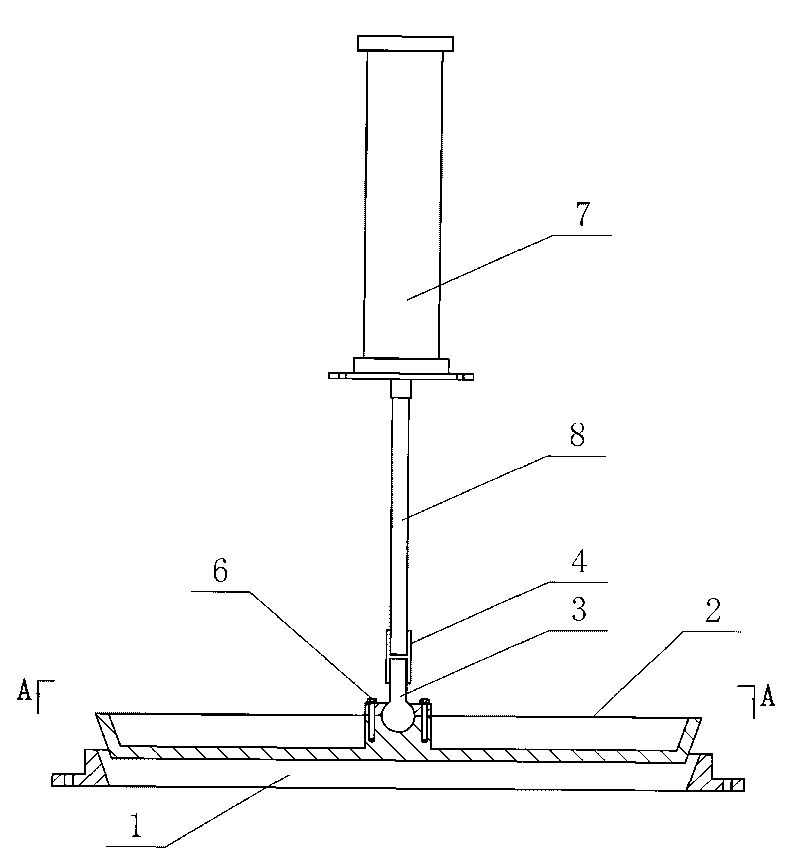

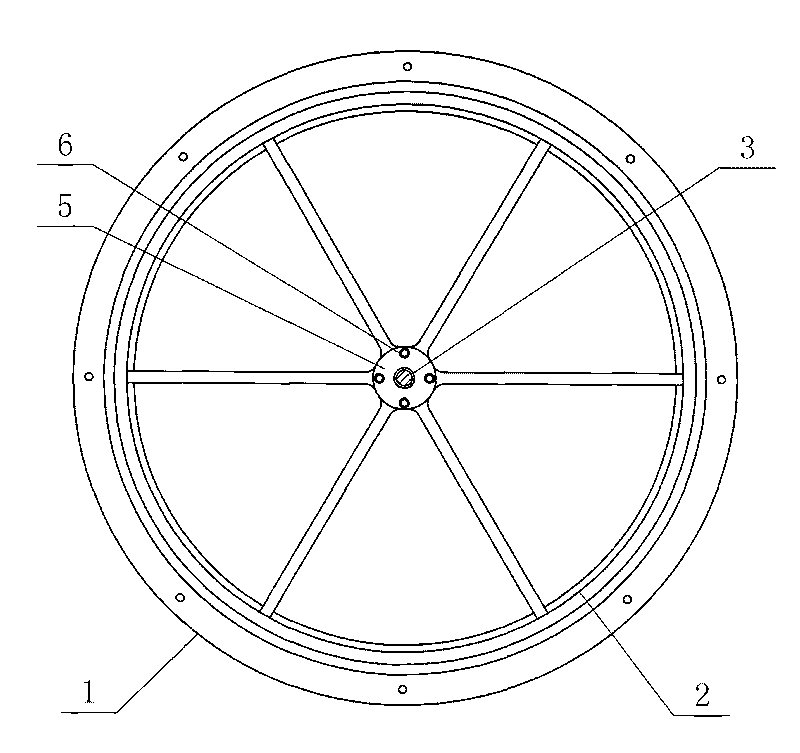

[0013] Such as figure 1 , figure 2 As shown, a self-aligning poppet valve includes a valve plate 2 and a cylinder 7. The lower part of the cylinder 7 is a cylinder rod 8, and the lower part of the cylinder rod 8 is provided with a section of external thread. The cylinder rod 8 is connected to the ball connecting rod through a connecting sleeve 4. 3 connection, a section of external thread is also provided on the upper part of the ball connecting rod 3, and an internal thread matching the external thread on the lower part of the cylinder rod 8 and the upper part of the ball connecting rod 3 is respectively provided at both ends of the connecting sleeve 4, so as to be socketed ; The ball connecting rod 3 and the valve plate 2 are flexibly connected, that is, a gland 5 is arranged on the upper side of the valve plate 2 middle, and a ball connecting rod is provided on the opposite side of the valve plate 2 and the gland 5. The hemispherical groove matched with the ball of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com