Slowly floating aquatic product feed and production process thereof

A kind of aquatic feed, slow technology, applied in animal feed, animal feed, climate change adaptation, etc., can solve the problems of increasing physical energy consumption, unfavorable feeding, etc., to achieve the effect of facilitating feeding, preventing gas leakage, and avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

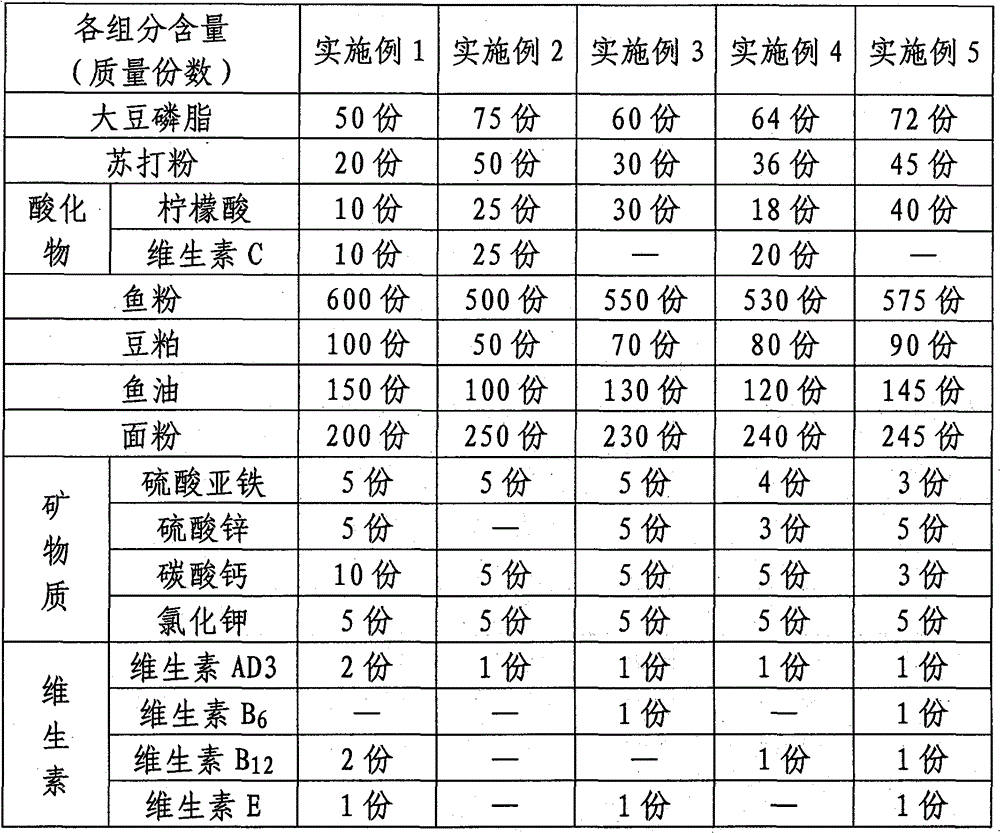

Embodiment 1

[0023] The slowly floating aquatic feed of the invention consists of soybean lecithin, soda powder, acid compound, fish oil, fish meal, soybean meal, flour, minerals and vitamins. The acid compound is a mixture of citric acid and vitamin C; the mineral is a mixture of ferrous sulfate, zinc sulfate, calcium carbonate and potassium chloride; and the vitamin is a mixture of vitamin A, vitamin D and vitamin E. The content of each component in the feed is calculated by mass fraction: 50 parts of soybean lecithin, 20 parts of soda powder, 10 parts of citric acid, 10 parts of vitamin C, 150 parts of fish oil, 600 parts of fish meal, 100 parts of soybean meal, 200 parts of flour, sulfite 5 parts of iron, 5 parts of zinc sulfate, 10 parts of calcium carbonate, 5 parts of potassium chloride, 2 parts of vitamin AD3, vitamin B 12 2 servings and 1 serving of vitamin E. The production process of the slowly floating aquatic feed comprises the following steps:

[0024] a. Take the raw mate...

Embodiment 2

[0030] The slowly floating aquatic feed of the invention consists of soybean lecithin, soda powder, acid compound, fish oil, fish meal, soybean meal, flour, minerals and vitamins. The acid compound is a mixture of citric acid and vitamin C; the mineral is a mixture of ferrous sulfate, calcium carbonate and potassium chloride; and the vitamin is vitamin A. The content of each component in the feed is calculated by mass fraction: 75 parts of soybean lecithin, 50 parts of soda powder, 25 parts of citric acid, 25 parts of vitamin C, 100 parts of fish oil, 500 parts of fish meal, 50 parts of soybean meal, 250 parts of flour, sulfite 5 parts of iron, 5 parts of calcium carbonate, 5 parts of potassium chloride and 31 parts of vitamin AD. The production process of the slowly floating aquatic feed comprises the following steps:

[0031] a. Take the raw materials according to the above proportioning ratio for subsequent use;

[0032] b. Mix soybean lecithin, soda powder and acid compo...

Embodiment 3

[0037] The slowly floating aquatic feed of the present invention is composed of soybean lecithin, soda powder, acid compound, fish oil, fish meal, soybean meal, flour, minerals and vitamins. The acid compound is citric acid; the mineral is a mixture of ferrous sulfate, zinc sulfate, calcium carbonate and potassium chloride; and the vitamin is a mixture of vitamin A, vitamin C and vitamin E. The content of each component in the feed is calculated according to the mass fraction: 60 parts of soybean lecithin, 30 parts of soda powder, 30 parts of citric acid, 130 parts of fish oil, 550 parts of fish meal, 70 parts of soybean meal, 230 parts of flour, 5 parts of ferrous sulfate, 5 parts of zinc sulfate, 5 parts of calcium carbonate, 5 parts of potassium chloride, 31 parts of vitamin AD, vitamin B 6 1 part and 1 part vitamin E. The production process of the slowly floating aquatic feed comprises the following steps:

[0038] a. Take the raw materials according to the above propor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com