Dispensable continuous negative-pressure puncture outfit

A disposable trocar technology, applied in the direction of suction instruments, trocars, etc., can solve the problems of low accuracy of fine needle aspiration cytopathology, bulky trocar feel, and backward use level, etc., to achieve simple structure and lighten the patient Painful, concentrated effort ensures the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

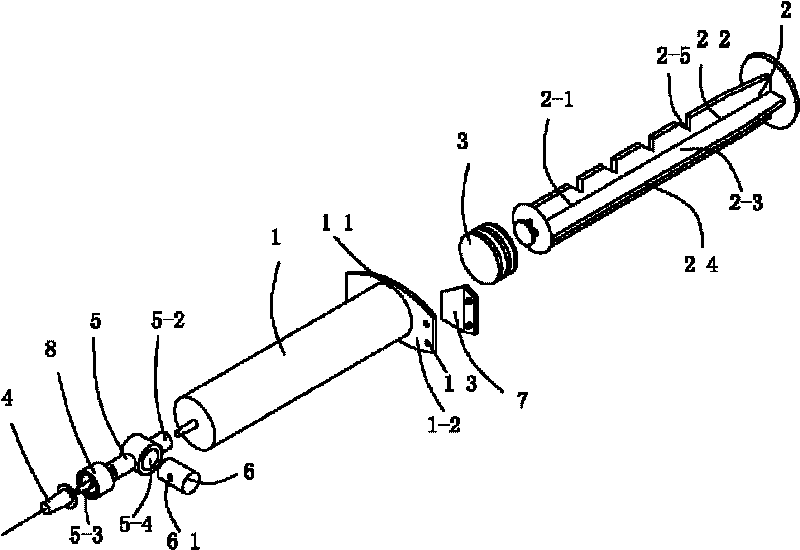

[0032] Disposable continuous negative pressure trocar embodiment, see figure 1 , the continuous negative pressure puncturer includes a needle tube 1, a needle plug 2 and a piston 3 in the needle tube, one end 2-1 of the needle plug is connected with the piston inside the needle tube, and the other end 2-2 is outside the needle tube, and is manually Pushing the needle pin back and forth drives the piston to move back and forth in the needle tube, a puncture needle 4 is arranged at the front end of the needle tube, and a stopper device is arranged between the puncture needle and the needle tube;

[0033] The stop-stop device is: a connecting tube 5, the connecting tube has a through hole 5-1, one end of the through hole is the needle tube interface 5-2, the other end of the through hole is the puncture needle interface 5-3, and the connecting tube is connected to the connecting tube. There is a control hole 5-4 in the middle, the control hole is set perpendicular to the through ...

Embodiment 2

[0037] Disposable continuous negative pressure puncture device preferred embodiment, see figure 1 As in Example 1, usually the docking of the puncture needle and the needle tube is a butt joint of a tapered mouth. In order to ensure a firm connection between the puncture needle and the connecting tube and an absolutely reliable seal, a The puncture needle locking nut 8, the rotation nut can lock the puncture needle firmly to ensure that the seal is absolutely reliable.

Embodiment 3

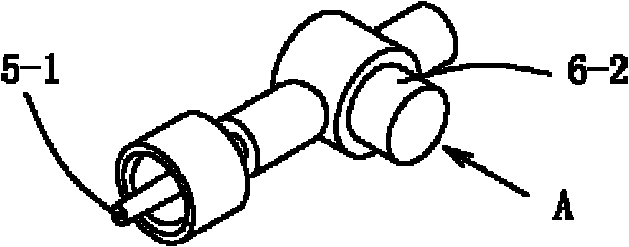

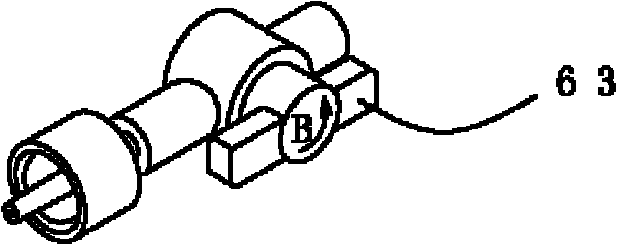

[0039] Disposable continuous negative pressure puncture device preferred embodiment, see figure 2 As in Example 1, the control hole can pass through the connecting pipe or not. The control hole in this embodiment is perpendicular to the through hole and runs through the connecting pipe. Cylinders connecting the side walls of pipes, such as figure 2 As shown in middle A, the cylinder moving laterally controls the connection and closure of the puncture needle and the needle tube through the connecting hole, and the shape of the cylinder matches the shape of the control hole, which is not limited to a cylinder, and can be rectangular or elliptical.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com