Drawer type hot wind heating mechanism

A hot air heating mechanism and drawer-type technology, applied in the field of heating devices, can solve the problems of unguaranteed product quality, increased application costs, and long heating time, so as to ensure the molding effect, avoid defective products and scrapping, and shorten the heating time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

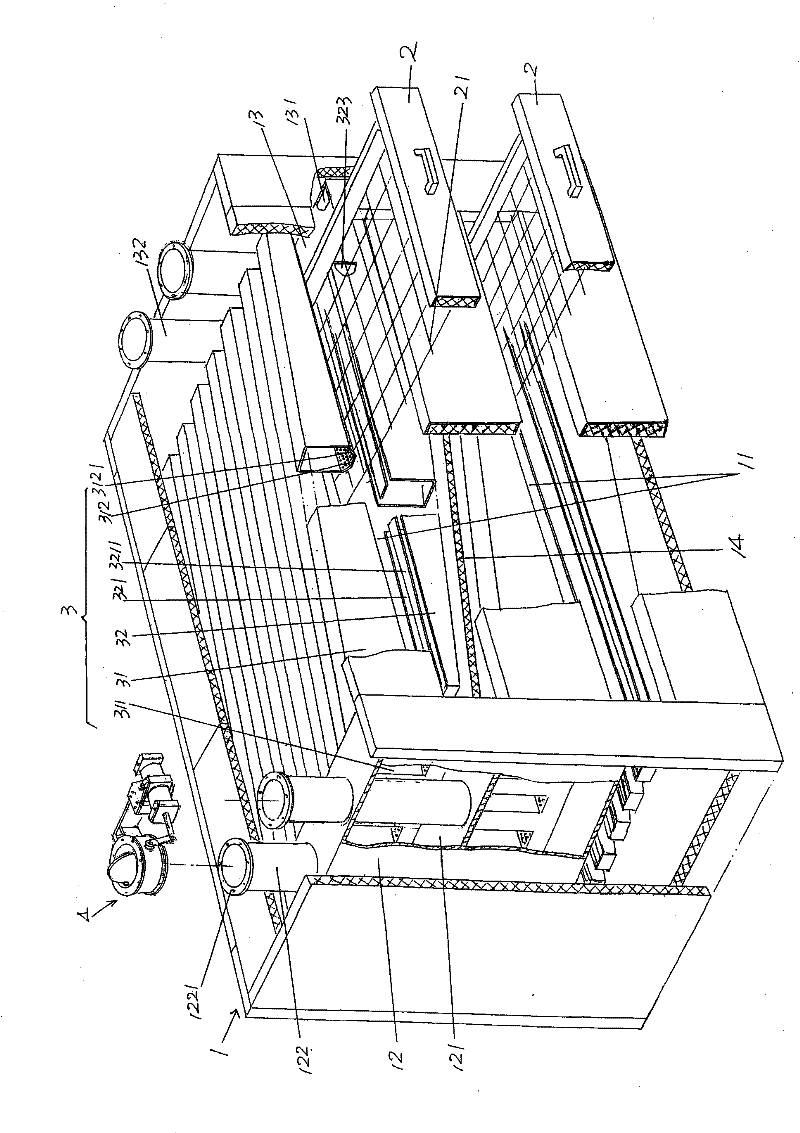

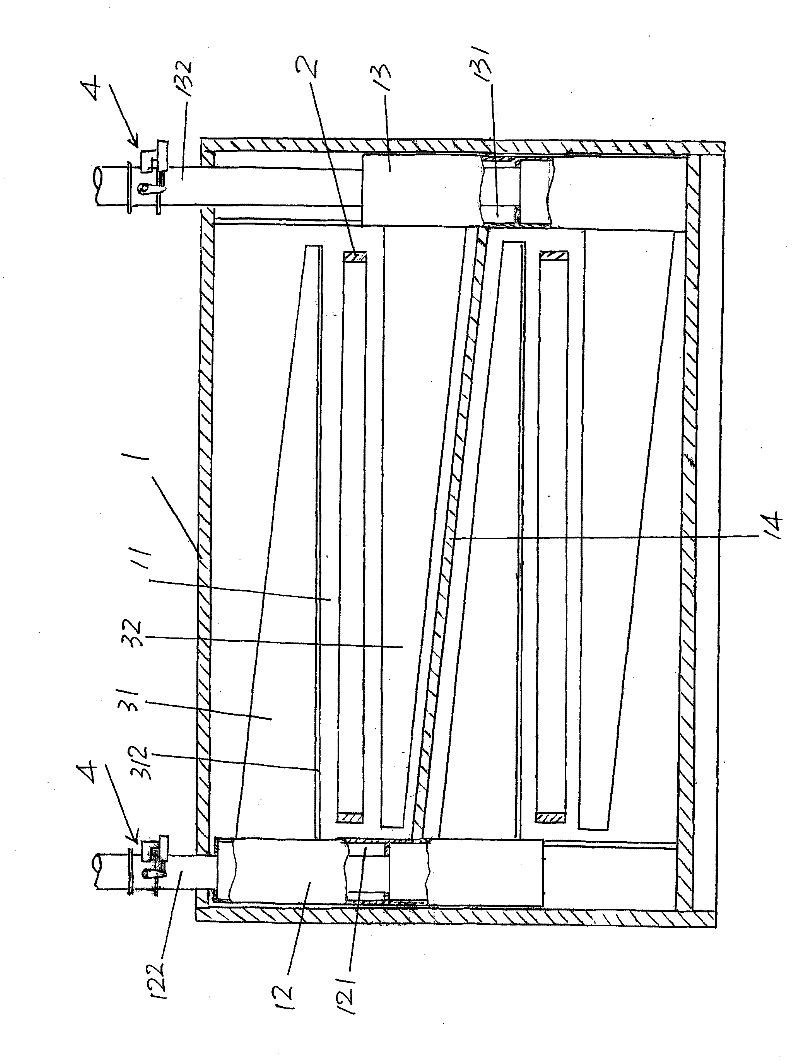

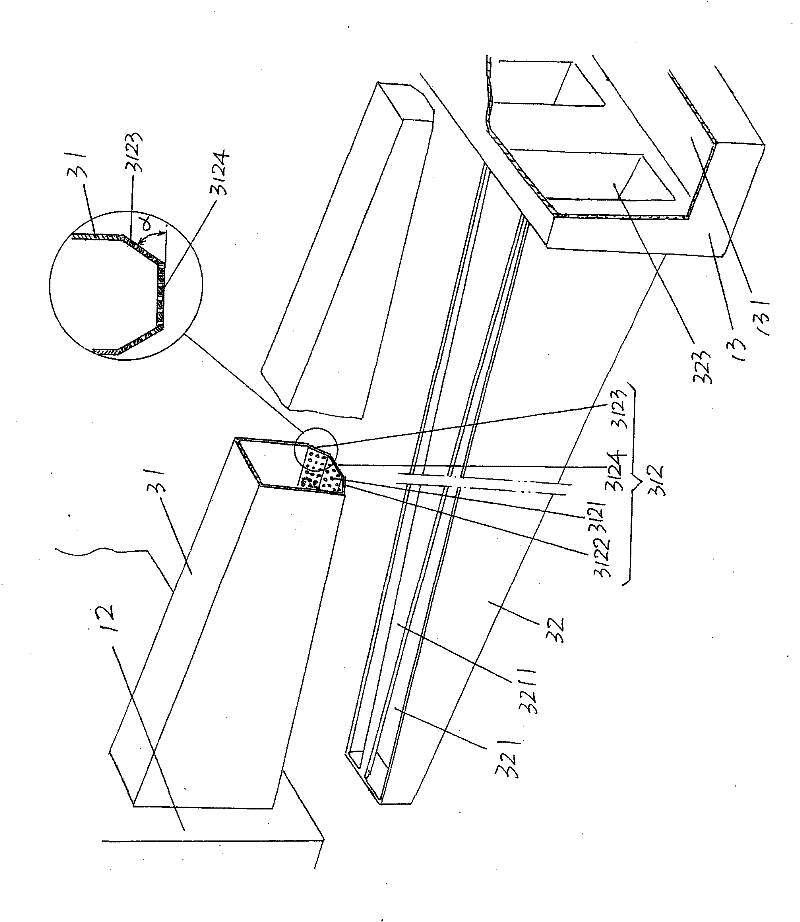

[0025] please see figure 1 and figure 2 , In this embodiment, a heating box body 1 with two heating chambers 11 is provided. Since there are an upper heating chamber 11 and a lower heating chamber 11, they are separated by a heating chamber partition plate 14 . As mentioned above, since there are two heating chambers 11, one end of the heating box body 1 is figure 1 and figure 2The shown left end is separated from two high-temperature air introduction boxes 12 in a vertical relationship with each other, and the right end of the heating box body 1 is also separated from a low-temperature air lead-in box 13 in a vertical relationship with each other, thus confirming the applicant's above The saying that the quantity of said low-temperature air derivation box 13 is equal to the quantity of high-temperature air introduction box 12, and the positions of low-temperature air derivation box 13 and high-temperature air introduction box 12 are corresponding, that is, both are in t...

Embodiment 2

[0031] Only change the number of heating chambers 11 to 3, the number of the corresponding material drawer 2, heating device 3, high-temperature air introduction box 12 and low-temperature air extraction box 13 is increased to three, and the heating chamber dividing plate 14 is increased to Two, all the other are the same as the description to embodiment 1.

Embodiment 3

[0033] Only change the number of heating chambers 11 to 5, and the number of corresponding material storage drawers 2, heating devices 3, high-temperature air introduction boxes 12 and low-temperature air outlet boxes 13 is increased to five, and the number of heating chamber partitions 14 is four. All the other are the same as the description of embodiment 1.

[0034] As can be seen from the foregoing embodiments, the inventive concept can be used to obtain as few as one heating chamber 11 and as many as the required number of heating chambers 11, so although the applicant has mentioned above that the number of heating chambers 11 is 1-7, it should not are absolutely limited.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com