Corrugated paper and manufacturing method thereof

A manufacturing method and technology of corrugated paper, applied in the direction of mechanical processing/deformation, etc., can solve problems such as unseen technical inspirations, and achieve the effects of ensuring printing effect, improving strength, and ensuring reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

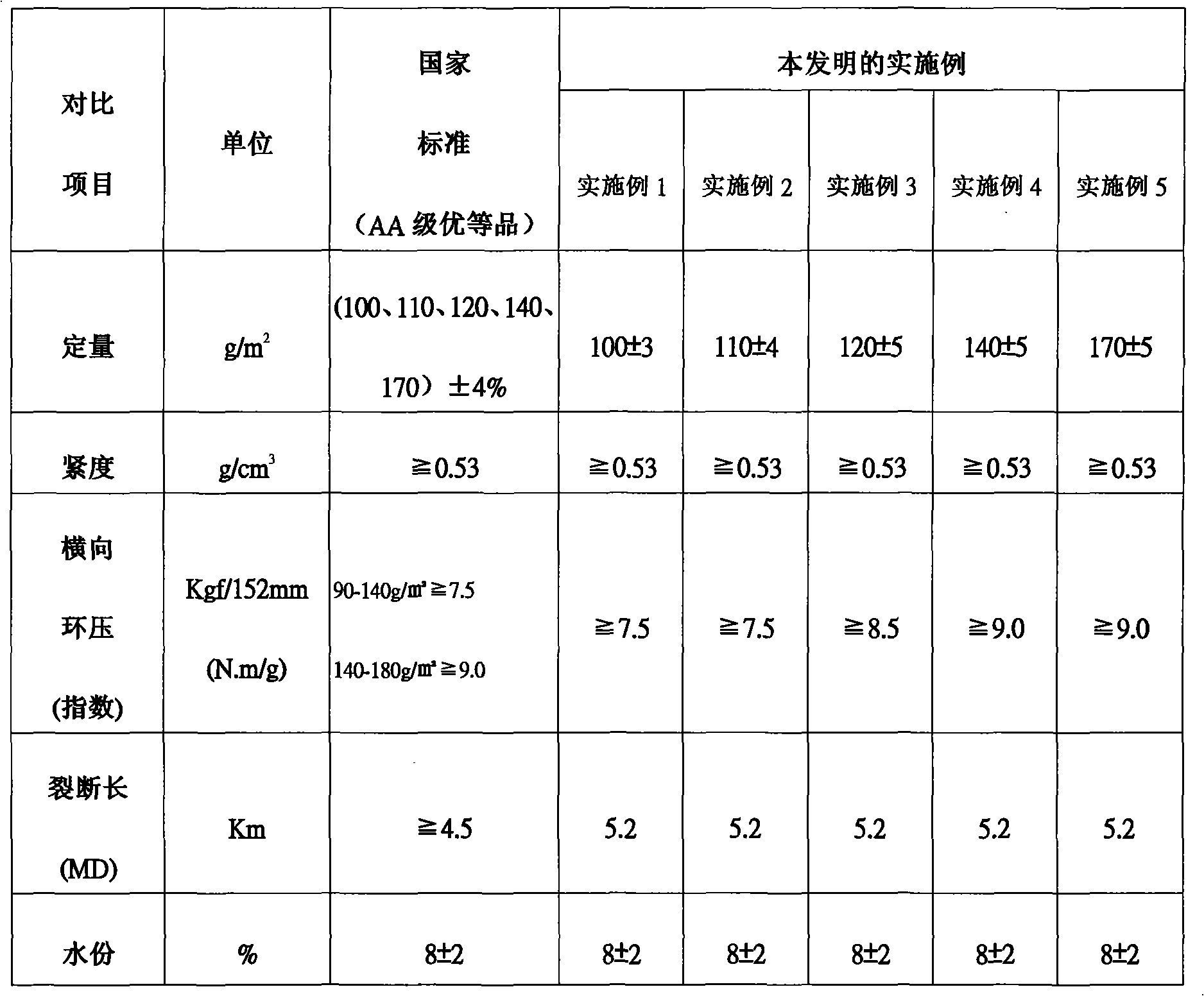

Examples

Embodiment 1

[0029] A) Ingredients, according to the weight ratio, select 60 parts of US 11# waste paper imported from the United States. The US 11# waste paper referred to here is the International Association Plumbing and Mechanical Officials (International Association Plumbing and Mechanical Officials). ) Established international standard certification norms PS-95 standard for waste corrugated box paper, the mass percentage of unqualified paper per 100 grams of waste paper in the United States 11# waste paper is <5.0% and is prohibited If the mass percentage content of the material is less than 1.0% and the moisture content is less than 12%, 30 parts of European waste paper are selected. The European waste paper referred to here is the mass percentage of miscellaneous paper per hundred grams of waste paper <29%, and the mass of impurities Recycled cardboard paper with a percentage of <1.0% and a moisture content of <12%, the miscellaneous paper referred to here is non-recycled cardboard,...

Embodiment 2

[0040] Only change the number of U.S. 11# waste paper in step A) to 45 parts, change the weight of European waste paper to 45 parts, and change the volume ratio of raw material to water in step B) to 100:4.5 , Change the amount of starch enhancer in step J) to 0.4g / m 2 Paper, change the amount of sizing agent to 2.2g / m 2 Paper and change the amount of surface gum starch to 8g / m 2 Paper and change the amount of surface sizing agent to 0.06g / m 2 paper. The rest are the same as the description of Embodiment 1.

Embodiment 3

[0042] Only change the weight parts of US 11# waste paper and European waste paper in step A) to 50 parts and 40 parts respectively, and change the volume ratio of raw material to water in step B) to 100:4, and change step J ) The amount of starch enhancer, the amount of sizing agent, the amount of surface gum starch and the amount of surface sizing agent were changed to 0.6g / m 2 Paper, 1.5g / m 2 Paper, 6g / m 2 Paper and 0.07g / m 2 paper. The rest are the same as the description of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com