Self-floating photothermal conversion hydrogel material as well as preparation method and application thereof

A photothermal conversion and hydrogel technology, applied in the fields of polymer materials and chemical materials, can solve the problems of high preparation cost, brittle material texture and inability to be used in a large area, poor mechanical properties of graphene aerogels, etc., which is time-consuming. Short, good buoyancy and stability, good for storage and preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

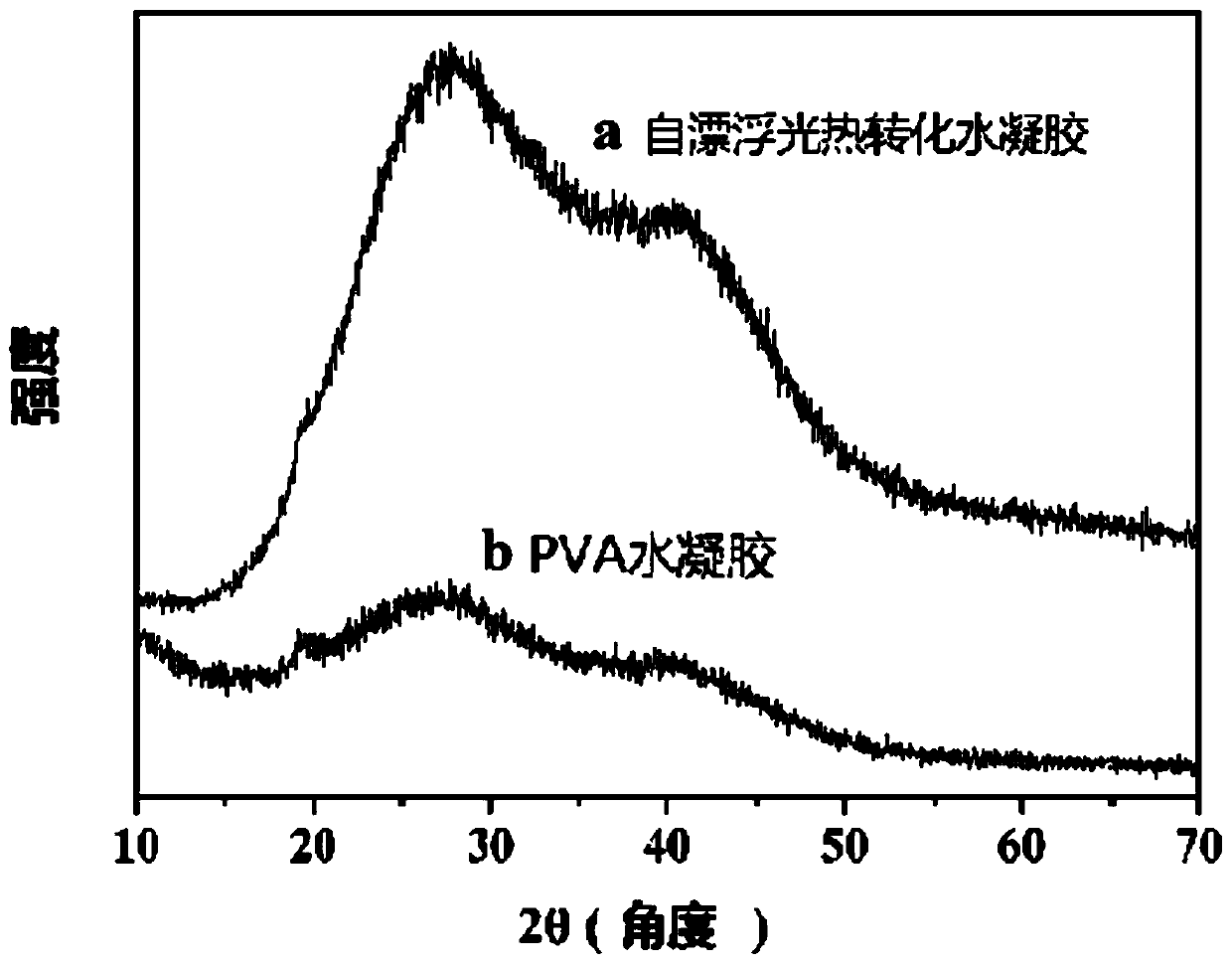

[0048] (1) Take 15g of polyvinyl alcohol (PVA), pour it into a three-necked flask, add 85ml of distilled water, take a constant temperature water bath at 100°C for 2 hours, stir at high speed to dissolve the PVA, and obtain a 15% aqueous solution of PVA;

[0049] (2) Weigh 14g of 15% polyvinyl alcohol (PVA) aqueous solution, grind the silica airgel (SA) until the particles are fine, and weigh 0.4g of the silica airgel. The two were uniformly mixed to obtain mixture A.

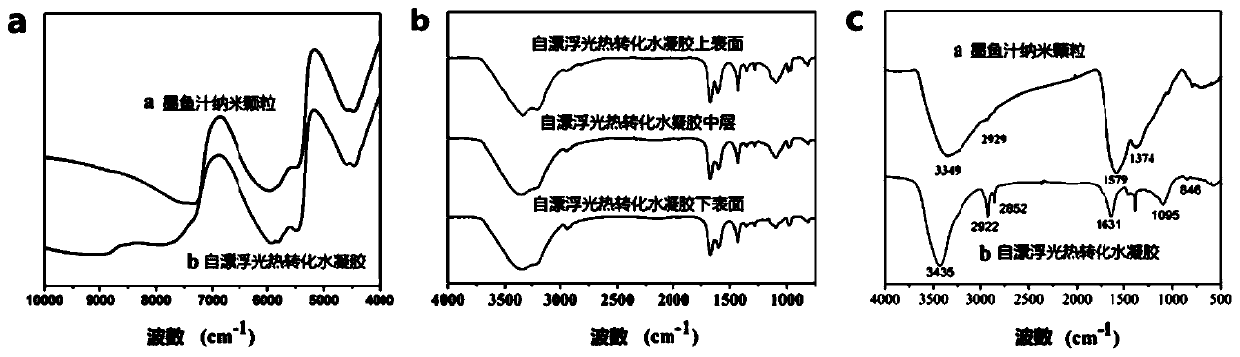

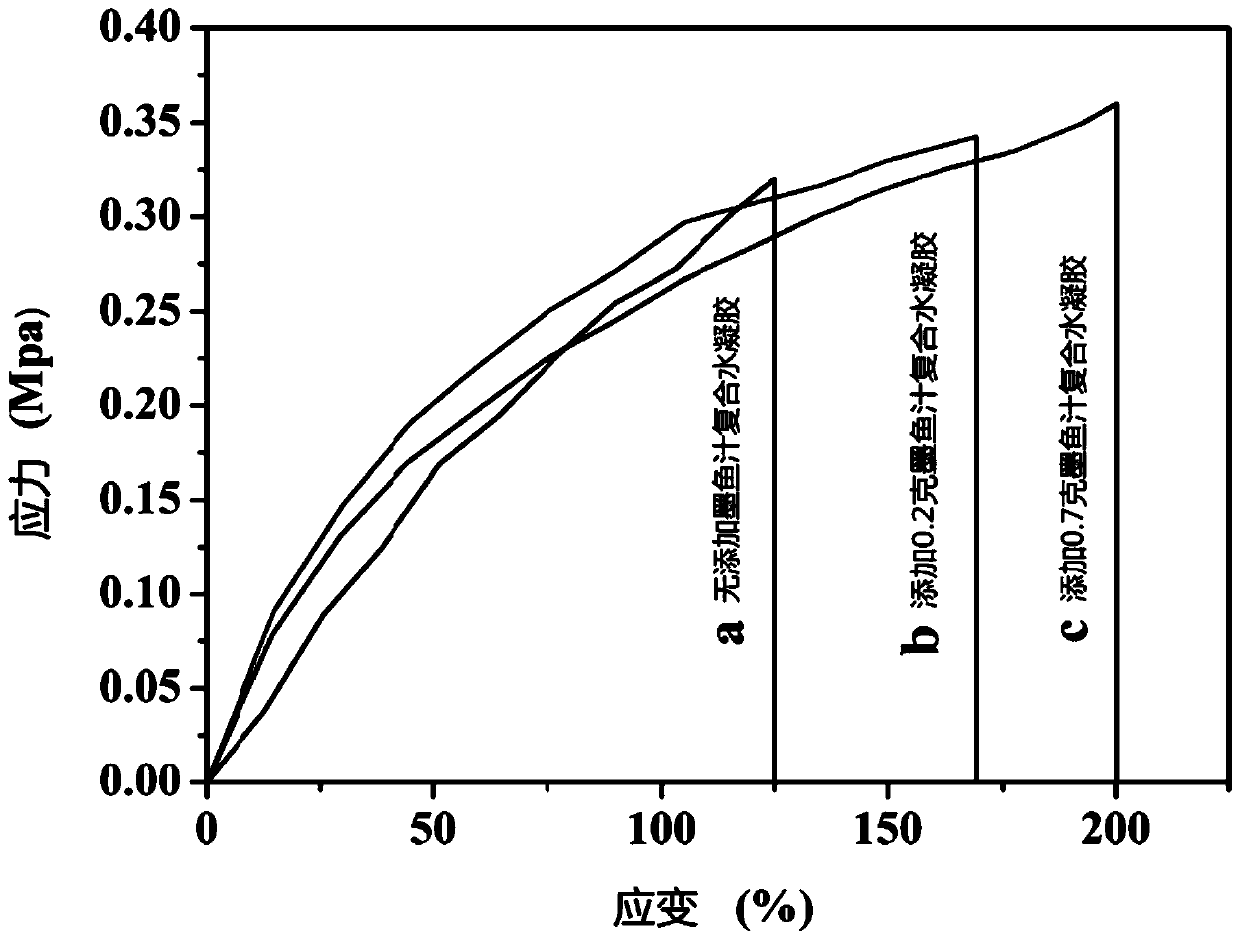

[0050] (3) Weigh 0.1g cuttlefish juice, 2g monoacrylamide, 0.03g N.N-methylene bisacrylamide, 0.04g ammonium persulfate, 0.08g polyethylene glycol dimethacrylate (PEGDA), 5.3g to Ionized water is uniformly mixed by ultrasonic waves. Then pass through nitrogen for 5 to 30 minutes to remove oxygen in the solution to obtain mixed solution B;

[0051] (4) Mix and stir the mixture A of step (2) and the mixed solution B of step (3), and use an ultrasonic instrument to sonicate for 40 minutes under the condition of ...

Embodiment 2

[0055] (1) Take 15g of polyvinyl alcohol (PVA), pour it into a three-necked flask, add 85ml of distilled water, take a constant temperature water bath at 100°C for 2 hours, stir at high speed to dissolve the PVA, and obtain a 15% aqueous solution of PVA;

[0056] (2) Weigh 14g of 15% polyvinyl alcohol (PVA) aqueous solution, grind the silica airgel to fine particles, and weigh 0.4g of silica airgel. The two were uniformly mixed to obtain mixture A.

[0057] (3) Weigh 0.2g cuttlefish juice, 2g monoacrylamide, 0.03g N.N-methylenebisacrylamide, 0.04g ammonium persulfate, 0.08g polyethylene glycol dimethacrylate (PEGDA), 5.3g to Ionized water is uniformly mixed by ultrasonic waves. Then pass through nitrogen for 5 to 30 minutes to remove oxygen in the solution to obtain mixed solution B;

[0058] (4) Mix and stir the mixture A of step (2) and the mixed solution B of step (3), and use an ultrasonic instrument to sonicate for 40 minutes under the condition of 45HZ to obtain a gel ...

Embodiment 3

[0062] (1) Take 15g of polyvinyl alcohol (PVA), pour it into a three-necked flask, add 85ml of distilled water, take a constant temperature water bath at 100°C for 2 hours, stir at high speed to dissolve the PVA, and obtain a 15% aqueous solution of PVA;

[0063] (2) Weigh 14g of 15% polyvinyl alcohol (PVA) aqueous solution, grind the silica airgel to fine particles, and weigh 0.4g of silica airgel. The two were uniformly mixed to obtain mixture A.

[0064] (3) Weigh 0.3g cuttlefish juice, 2g monoacrylamide, 0.03g N.N-methylene bisacrylamide, 0.04g ammonium persulfate, 0.08g polyethylene glycol dimethacrylate (PEGDA), 5.3g to Ionized water is uniformly mixed by ultrasonic waves. Then pass through nitrogen for 5 to 30 minutes to remove oxygen in the solution to obtain mixed solution B;

[0065] (4) Mix and stir the mixture A of step (2) and the mixed solution B of step (3), and use an ultrasonic instrument to sonicate for 40 minutes under the condition of 45HZ to obtain a gel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com