Polymer composite microsphere, preparation method and drug loading application thereof

A technology of composite microspheres and polymers, applied in the direction of antineoplastic drugs, microcapsules, nanocapsules, etc., to achieve the effect of simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] According to the above technical solution, this embodiment provides a polymer composite microsphere and a preparation method.

[0043] Include the following steps:

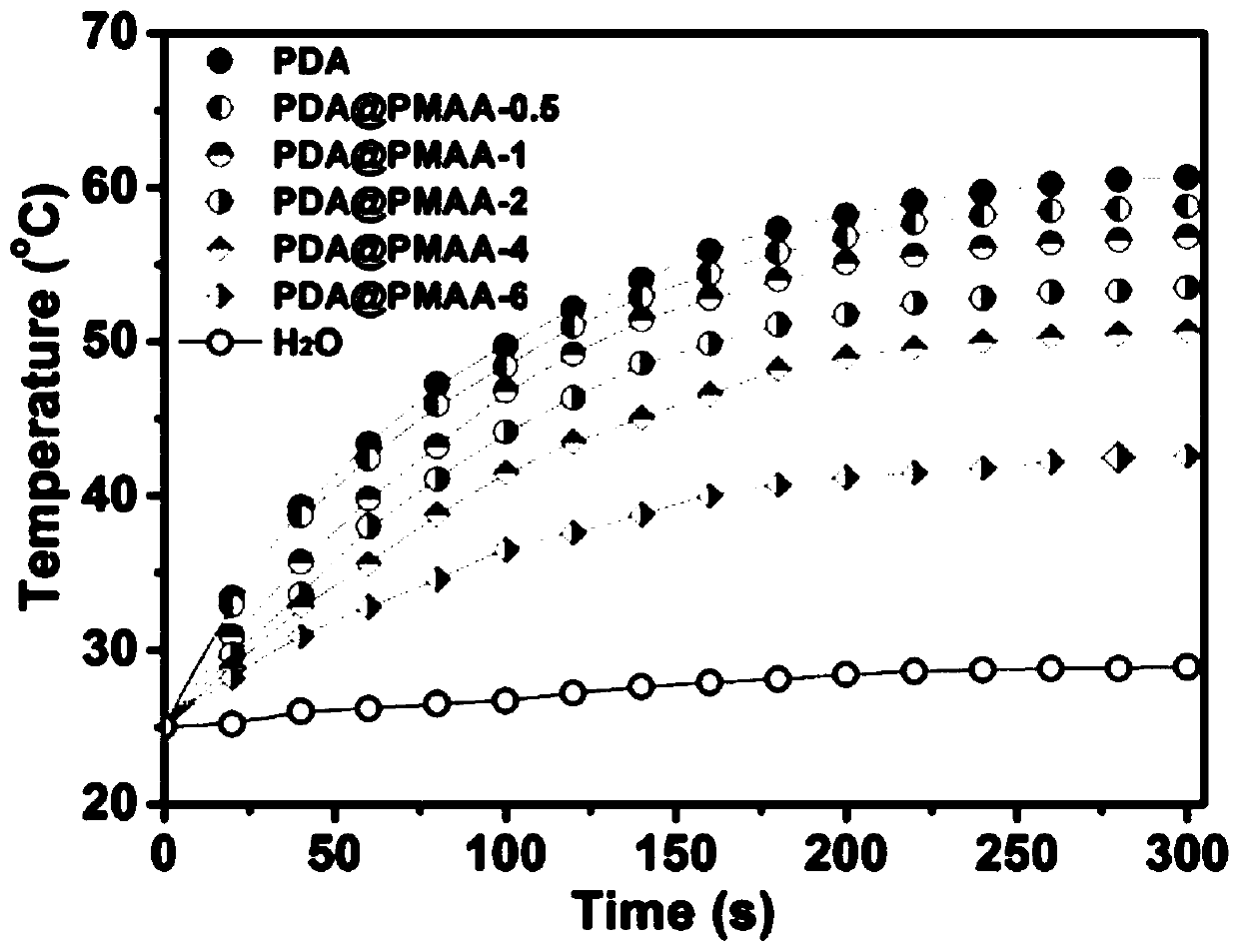

[0044] Step 1: adding dopamine hydrochloride (DA·HCl) to the solvent and reacting in a warm water bath to prepare PDA (polydopamine) nanospheres with good light-to-heat conversion performance. Take 40mL of ethanol, 90mL of water and 3mL of concentrated ammonia water, add them to a 250mL three-necked flask in turn and stir in a 30°C water bath for 30min, maintaining a mechanical stirring rate of 250rpm. Add 0.5gDA·HCl pre-dissolved in 10mL deionized water into the three-necked flask, and react for 24h. The product was centrifuged (50000rpm, 10min), and washed with deionized water until neutral. 50 mg of PDA nanospheres were separated by centrifugation.

[0045] Step 2: using the distillation precipitation polymerization method to coat the polymer shell on the PDA nanospheres obtained in step 1 to prepare ...

Embodiment 2

[0047] Same as the method in Example 1. However, the difference from Example 1 is: accurately weigh 50 mg MAA, 1.50 mg AIBN, 5.00 mg BAC and 50 mg PDA nanospheres, and the rest of the steps are the same. Obtain polymer composite microsphere PDA@PMAA-1 (the ratio of the mass ratio of MAA and PDA is 1), such as figure 1 As shown in (c), the particle size of PDA@PMAA-1 is 190nm.

Embodiment 3

[0049] Same as the method in Example 1. However, the difference from Example 1 is: accurately weigh 100mg MAA, 3.00mgAIBN, 10mg BAC and 50mg PDA nano-microspheres, and the rest of the steps are the same. Obtain polymer composite microsphere PDA@PMAA-2 (the ratio of the mass ratio of MAA and PDA is 2), as figure 1 As shown in (d), the particle size of PDA@PMAA-2 is 227 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com