Near-infrared light response electrostatically spun PCL/MoS2 nanofiber membrane and preparation method thereof

A near-infrared light-responsive, nanofiber membrane technology, used in pharmaceutical formulations, textiles and papermaking, medical science, etc., can solve the problems of limited therapeutic effect and low heat transfer efficiency, and achieve good biocompatibility and high mechanical properties. , good hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The near-infrared photoresponsive electrospun PCL / MoS was prepared according to the following steps 2 Nanofiber Membrane:

[0035] S1. At room temperature, dissolve 0.4g of PCL in 5mL of hexafluoroisopropanol organic solution, place it on a magnetic stirrer and stir for 12 hours, ultrasonicate for half an hour, put the fully mixed solution into a syringe, and conduct electrospinning by electrospinning. Spinning (voltage 15kV, speed 0.8mL / h, distance 15cm)

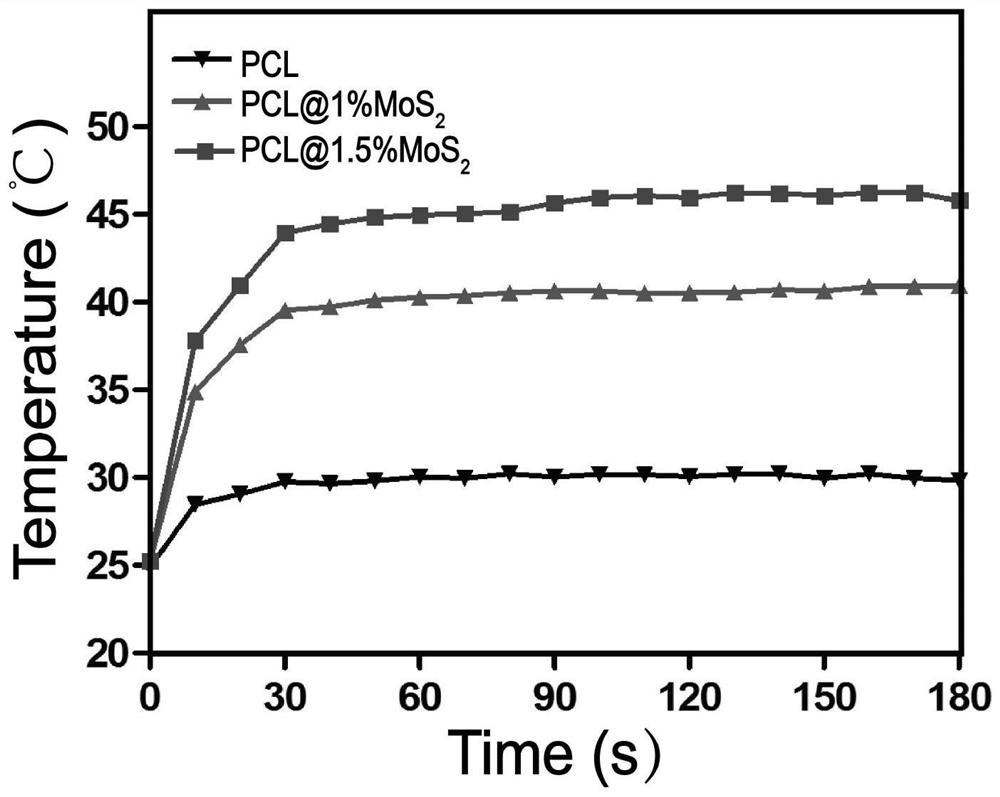

[0036] S2. Combine PCL and PCL / MoS 2 The fiber membrane is cut into a disc with a diameter of about 1.6cm, and the reuse power density is 0.5W / cm 2 808nm near-infrared light irradiation to verify its photothermal conversion performance. Lighting conditions: light power 1W, light distance 5.6cm, light time 180s.

Embodiment 2

[0038] The near-infrared photoresponsive electrospun PCL / MoS was prepared according to the following steps 2 Nanofiber Membrane:

[0039] S1. At room temperature, add 0.05g MoS 2 Dissolve in 5mL hexafluoroisopropanol organic solution, place on a magnetic stirrer and stir for 6 hours, then add 0.4g PCL, stir for 12 hours, ultrasonic for half an hour, put the fully mixed solution into a syringe, and use electrospinning Electrospinning (voltage 15kV, speed 0.8mL / h, distance 15cm)

[0040] S2. Combine PCL and PCL / MoS 2 The fiber membrane is cut into a disc with a diameter of about 1.6cm, and the reuse power density is 0.5W / cm 2 808nm near-infrared light irradiation to verify its photothermal conversion performance. Lighting conditions: light power 1W, light distance 5.6cm, light time 180s.

Embodiment 3

[0042] The near-infrared photoresponsive electrospun PCL / MoS was prepared according to the following steps 2 Nanofiber Membrane:

[0043] S1. At room temperature, add 0.075g MoS 2 Dissolve in 5mL hexafluoroisopropanol organic solution, place on a magnetic stirrer and stir for 6 hours, then add 0.4g PCL, stir for 12 hours, ultrasonic for half an hour, put the fully mixed solution into a syringe, and use electrospinning Electrospinning (voltage 15kV, speed 0.8mL / h, distance 15cm)

[0044] S2. Combine PCL and PCL / MoS 2The fiber membrane is cut into a disc with a diameter of about 1.6cm, and the reuse power density is 0.5W / cm 2 808nm near-infrared light irradiation to verify its photothermal conversion performance. Lighting conditions: light power 1W, light distance 5.6cm, light time 180s.

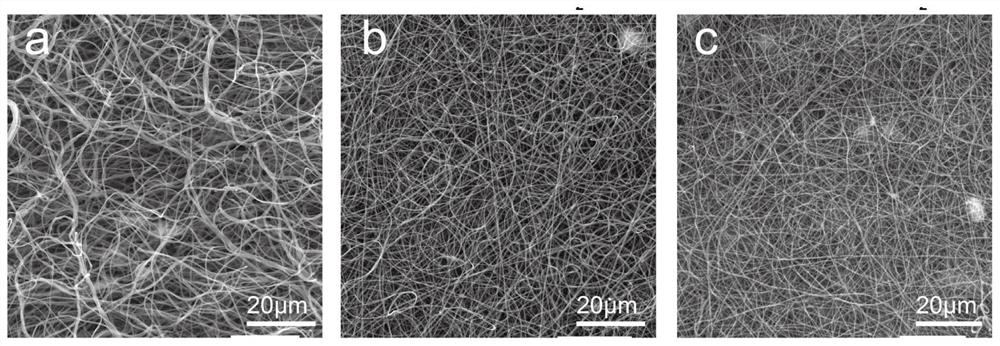

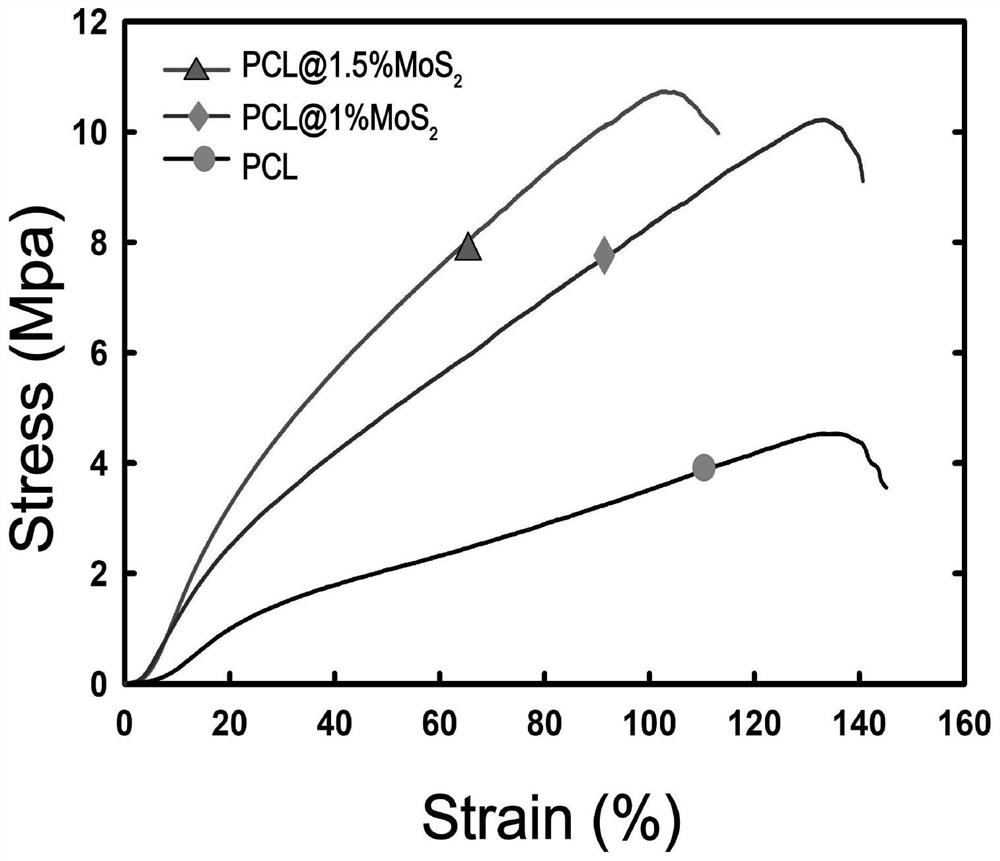

[0045] attached by figure 1 It can be seen that electrospun PCL and PCL / MoS 2 The fiber structure of the fiber membrane under the electron microscope is uniform, and the fiber surface i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com