Delta-MnO2/SiO2 composite nanofiber with light-driven thermal degradation function and preparation and application thereof

A technology of composite nanofibers and nanofibers, which can be used in fiber processing, metal/metal oxide/metal hydroxide catalysts, filament/wire forming, etc. Material application, secondary pollution and other issues, to achieve good photothermal conversion performance, significant light-driven thermocatalytic degradation function, and temperature reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Step 1. Preparation of SiO 2 nanofiber membrane

[0050] (1) Using TEOS, phosphoric acid and water as raw materials, the molar ratio of TEOS, phosphoric acid and water is 1:0.01:10, stirring at 25°C for 1 hour to obtain spinning solution A;

[0051] (2) Using PVA and water as raw materials, 1 g of PVA was dissolved in 10 ml of deionized water, and stirred at 60° C. for 3 hours to obtain spinning solution B;

[0052] (3) Take 1 g of spinning solution A, add it dropwise to spinning solution B, control the mass ratio of solutions A and B to be 1:1, and stir for 6 hours at 25°C;

[0053] (4) An electrospinning machine with a single propulsion pump and a single moving platform is adopted, and the moving speed of the platform is 60mm / min; the electrospinning voltage is +18Kv, and the flow rate is controlled to be 0.02ml / min, and the drum is used as the collecting device and the rotating speed is 500r / min, the distance between the electrospinning nozzle and the receiving dru...

Embodiment 2

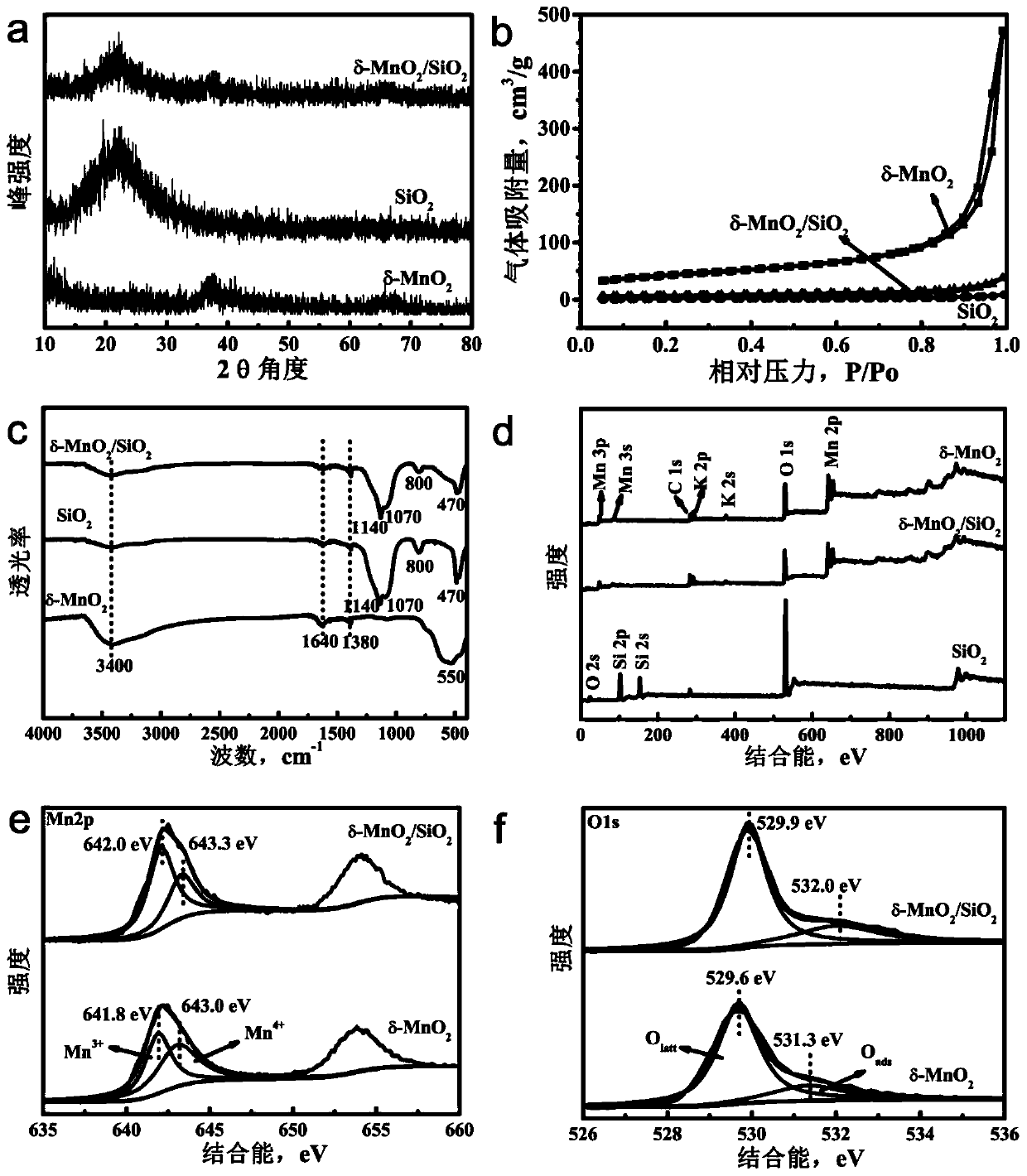

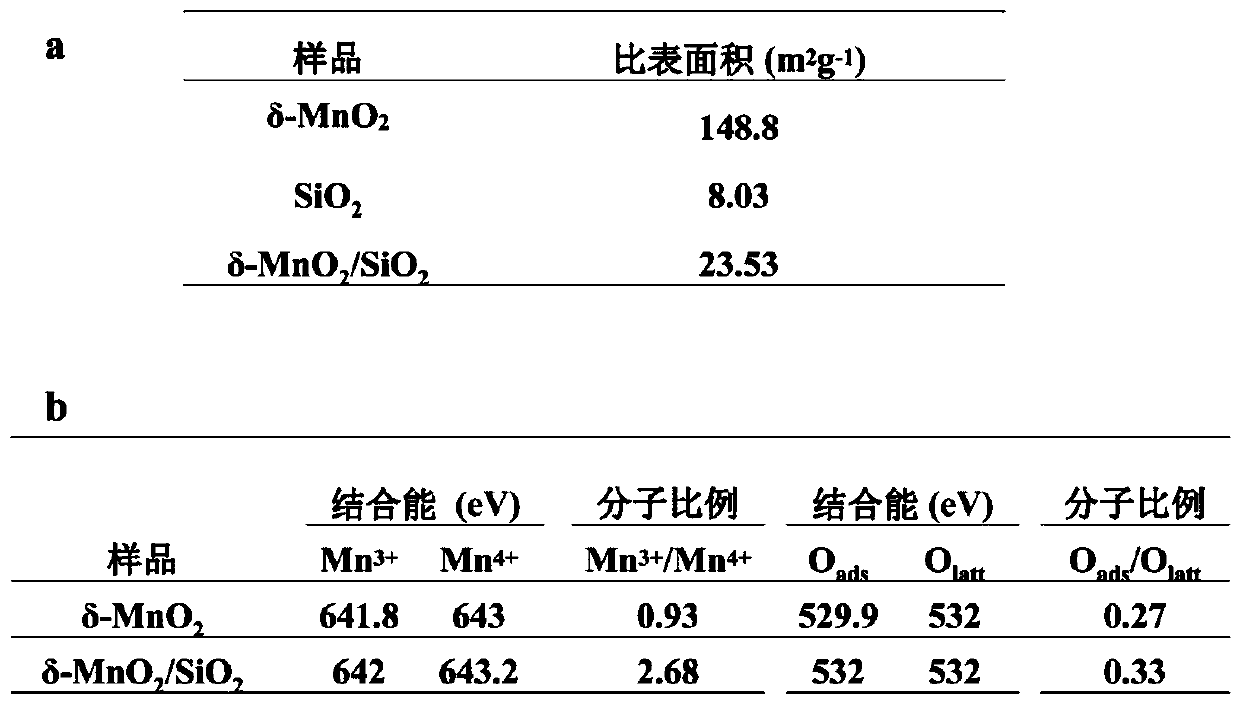

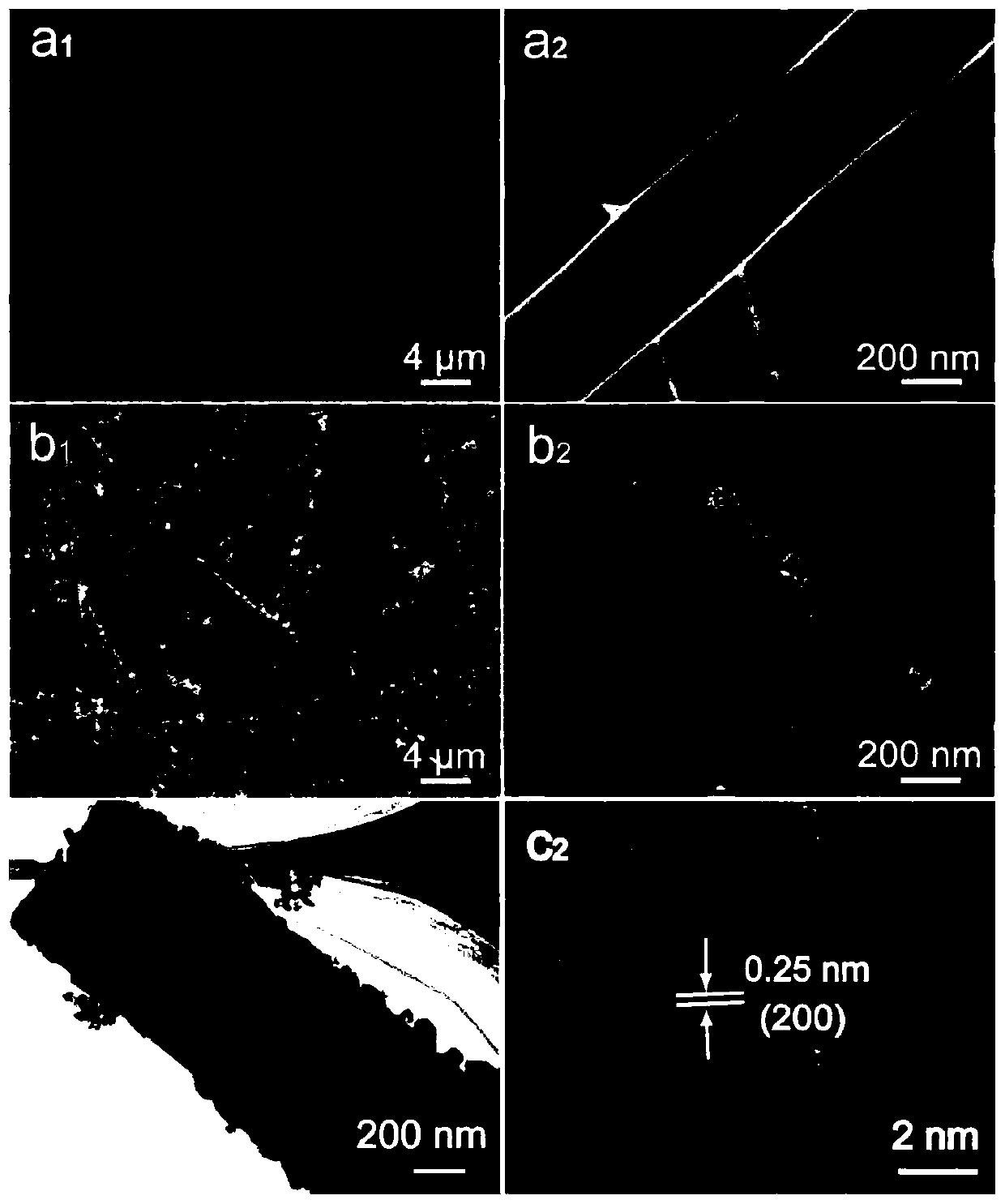

[0061] Get the δ-MnO prepared in Example 1 2 Particles, SiO 2 Nanofibers and δ-MnO 2 / SiO 2 Composite nanofibers were tested for photothermal conversion and static photothermal catalysis and dynamic photothermal catalysis experiments of toluene.

[0062] 1. Photothermal conversion performance test

[0063] Using a 300w xenon lamp to simulate sunlight, the cut 2cm×2cm δ-MnO 2 / SiO 2 Composite nanofibers, SiO 2 Nanofibers and δ-MnO 2 The particles were placed directly under the xenon lamp light source, with a distance of 15 cm, and at intervals of 1 min, the temperature under the irradiation of the xenon lamp was measured by a thermocouple.

[0064] Such as Figure 6 As shown in a, δ-MnO 2 / SiO 2 The composite nanofiber is irradiated by a 300w xenon lamp to simulate full-band sunlight, and the temperature rises rapidly to about 225°C within 5 minutes.

[0065] Such as Figure 6 b UV-Vis diffuse reflectance curve, δ-MnO 2 / SiO 2 Composite nanofibers have a certain d...

Embodiment 3

[0079] Step 1. Preparation of SiO 2 nanofiber membrane

[0080] (1) Using TEOS, phosphoric acid and water as raw materials, the molar ratio of TEOS, phosphoric acid and water is 1 / 0.01 / 10, stirring at 25°C for 3 hours to obtain spinning solution A;

[0081] (2) Using PVA and water as raw materials, 1.2g of PVA was dissolved in 10ml of deionized water, and stirred at 60°C for 6h to obtain spinning solution B;

[0082] (3) Take 1 g of spinning solution A, add it dropwise to spinning solution B, control the mass ratio of solutions A and B to be 1:1.5, and stir for 8 hours at 25°C;

[0083] (4) An electrospinning machine with a single propulsion pump and a single moving platform is adopted, and the moving speed of the platform is 60mm / min; the electrospinning voltage is +15Kv, and the flow rate is controlled to be 0.04ml / min, and the drum is used as the collecting device and the rotating speed is 500r / min, the distance between the electrospinning nozzle and the receiving drum is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com