Edge clamping strip correcting device

A technology of regulation and edge clamping, which is applied in the field of mechanical adjustment devices for cathode plates, can solve problems such as loosening of edge clamps and hindering the recycling of cathode plates, so as to improve production efficiency and ensure normal and repeated use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

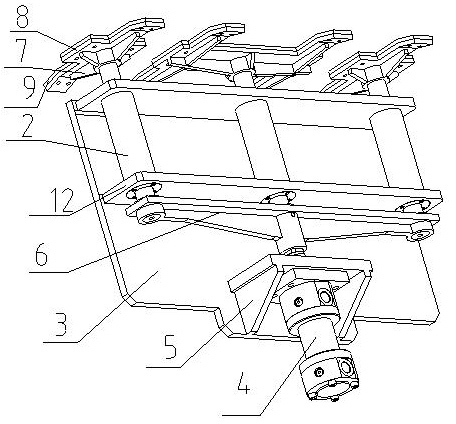

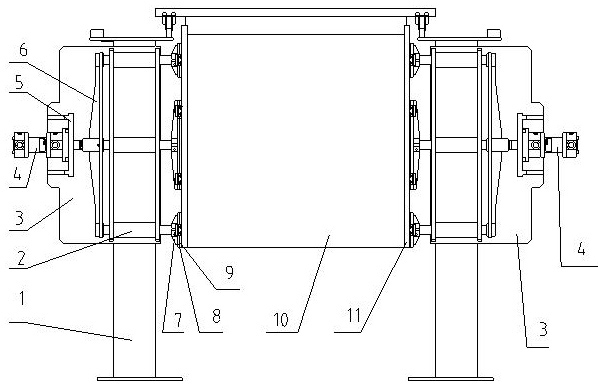

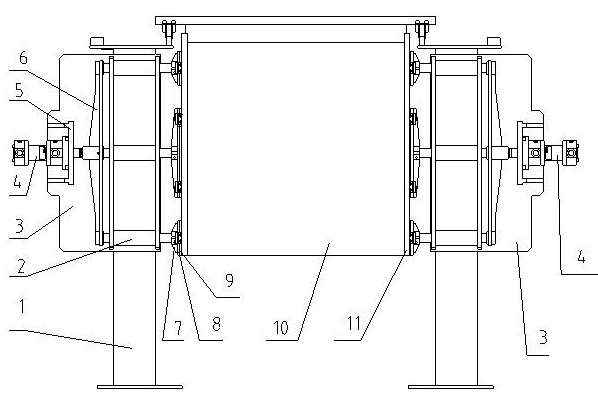

[0017] Embodiment: clamping strip regularizing device (referring to appendix figure 1 , 2 ), mainly consists of a cylinder 4, a cylinder support 5, a bottom plate 3, a sleeve body, a linkage plate 6, a guide column and a pressure plate 8, and the sleeve body includes 12 vertically placed fixed plates on both sides and 3 fixed On the sleeve 2 on the fixed plate 12, the sleeve 2 is vertically arranged; the guide column is matched with the sleeve 2 and the middle part of the guide column is sleeved in the sleeve, and one side of the guide column is fixed on the linkage plate 6 On one side of the guide column, the other side of the guide column is fixedly connected with the pressure plate 3; the other side of the linkage plate 6 is fixedly connected with the movable end of the cylinder 4, and the cylinder 4 is fixed on the cylinder support 5, and the cylinder support 5 and the sleeve The cylinders are all fixed on the bottom plate 3 arranged vertically. The inner side of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com