Fast positioning device of automobile glass tempered air grid

A glass tempering and positioning device technology, which is applied in glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high installation accuracy, low mold change efficiency, and large air grille volume, so as to ensure the corresponding size of the hole position Accuracy, the effect of reducing mold change time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

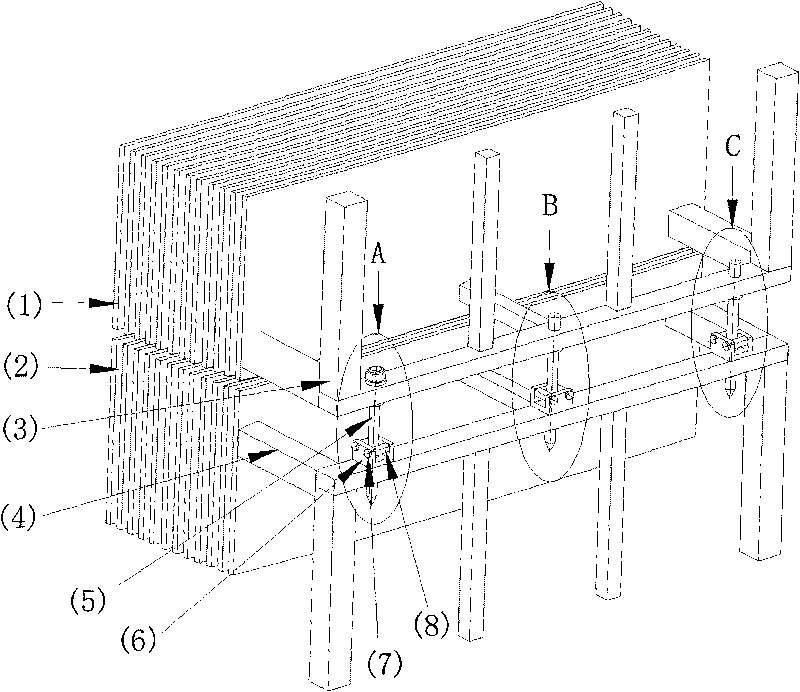

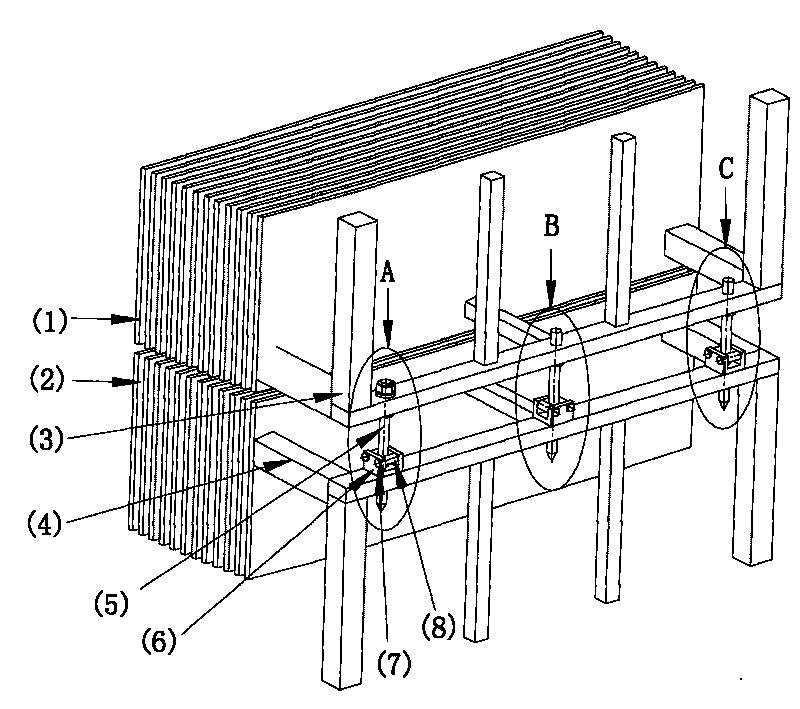

[0015] like figure 1 As shown, the design and application technology of the air grille quick positioning device, its process is: as shown in the figure, the convex air grille 1, the concave air grille 2, three pairs of guide devices A, B, C are respectively installed on the convex and concave air grille brackets, The other side of the grid is symmetrically installed, and there are six sets of guide devices in total, among which the guide column 5 is fixed on the bracket 3 of the convex wind grid. A positioning shaft pin 7 can be slipped and flexibly rotated, and the positioning shaft pin 7 and the positioning shaft 8 are fixed on the positioning shaft seat 6. The outer distance between the two positioning shafts 8 is equal to the diameter of the guide column 5, and its tolerance is that the diameter of the guide column deviates. Smaller than the pitch or slip fit of the positioning axis. The positioning shaft seat 6 is fixed on the concave wind grid support 4, and the guide c...

Embodiment 2

[0017] A quick positioning device for glass tempered air grilles of automobiles, the device includes three pairs of guide devices and air grilles, wherein the first pair of guide devices and the third pair of guide devices are respectively installed on the front and rear sides of the air grilles to locate the front and rear positions of the air grilles, the first Two pairs of guiding devices are installed on both sides of the middle of the air grille to locate the left and right positions of the air grille. The guide device includes a guide column, a positioning shaft seat, a positioning shaft pin and a positioning shaft. There are two positioning shafts, which are arranged in parallel on the positioning shaft seat, fixed by the positioning shaft pin, and the positioning shaft is on the positioning shaft pin It can be slipped and rotated flexibly. The guide column is connected to the positioning shaft seat; the air grid includes a convex grid, a concave grid, a convex grid bra...

Embodiment 3

[0019] A quick positioning device for glass tempered air grilles of automobiles, the device includes three pairs of guide devices and air grilles, wherein the first pair of guide devices and the third pair of guide devices are respectively installed on the front and rear sides of the air grilles to locate the front and rear positions of the air grilles, the first Two pairs of guiding devices are installed on both sides of the middle of the air grille to locate the left and right positions of the air grille. The guide device includes a guide column, a positioning shaft seat, a positioning shaft pin and a positioning shaft. There are two positioning shafts, which are arranged in parallel on the positioning shaft seat, fixed by the positioning shaft pin, and the positioning shaft is on the positioning shaft pin Can be slip-fit and flexibly rotated. The guide column is connected to the positioning shaft seat; the air grid includes a convex grid, a concave grid, a convex grid bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com