Hydraulic buffer

A technology of hydraulic buffers and liquid chambers, applied in the field of hydraulic buffers, can solve problems such as obstructing circulation and affecting the telescopic action of a piston rod, and achieve the effect of preventing discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

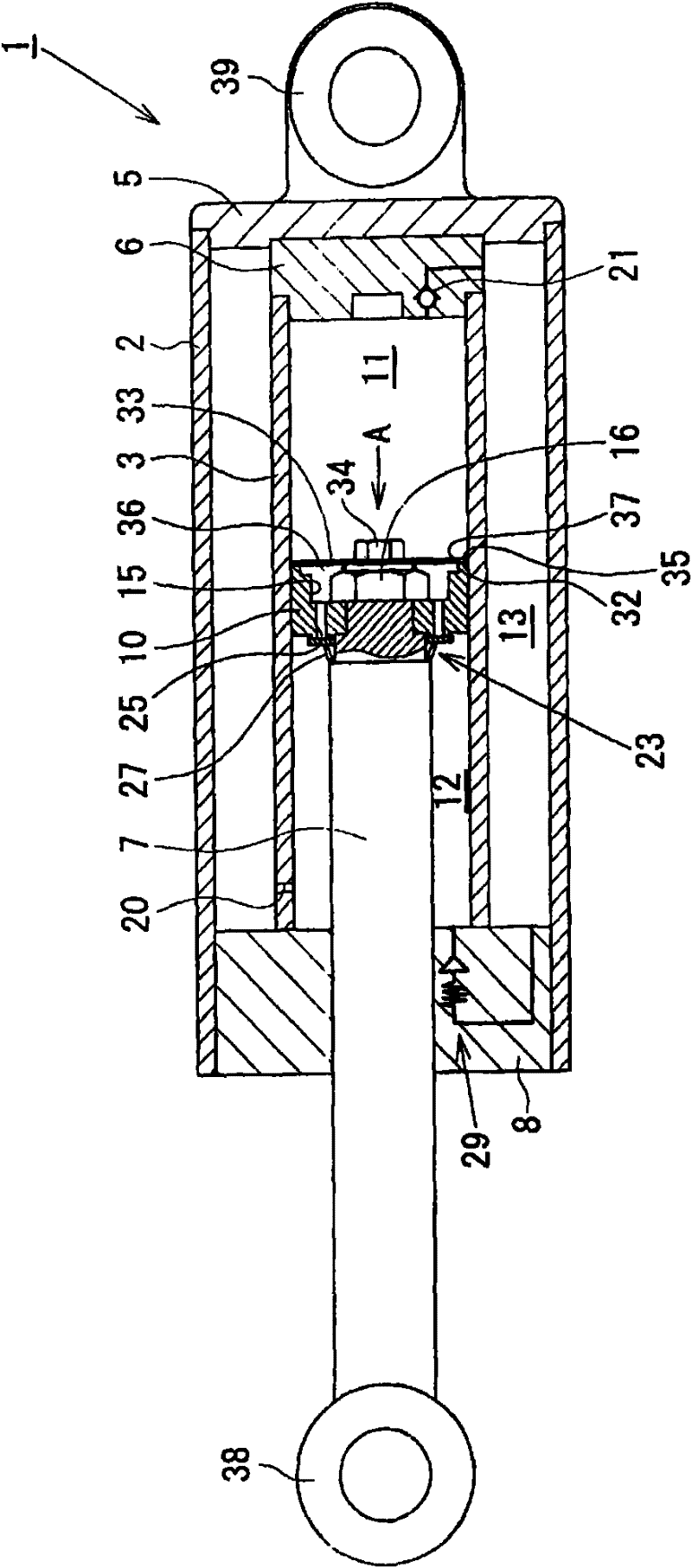

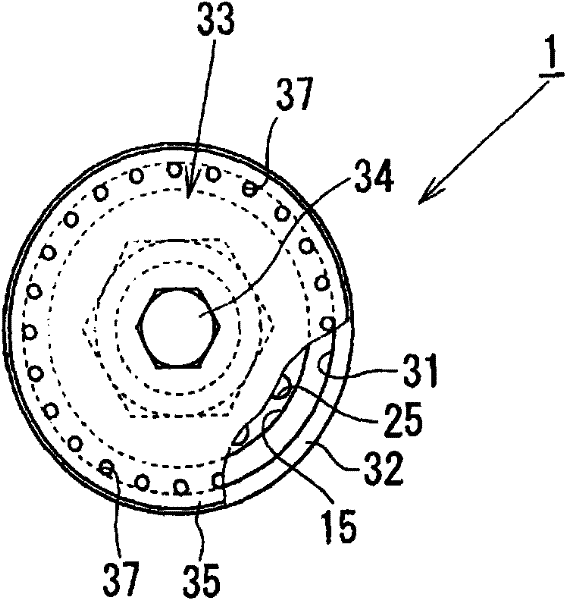

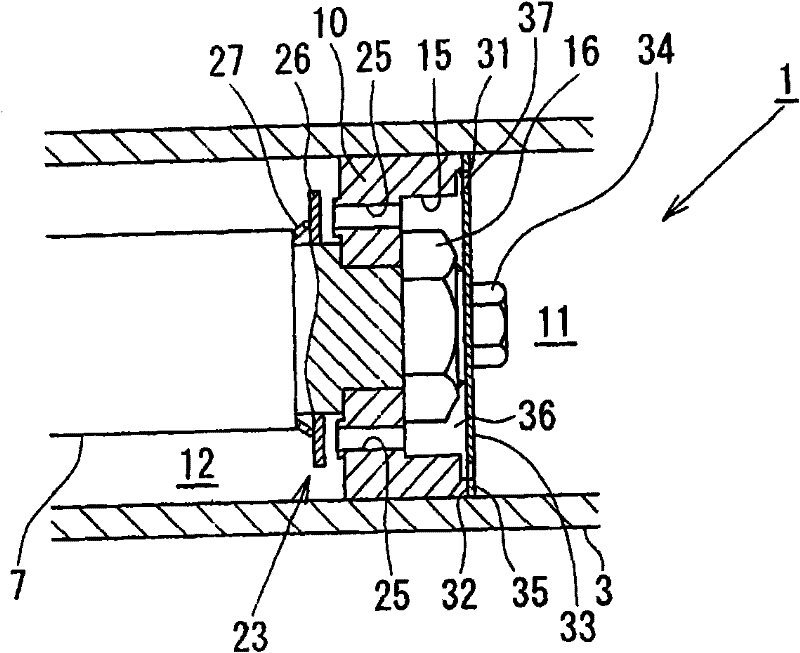

[0022] The following will be based on Figure 1-9 Preferred embodiments for implementing the present invention are described in detail. As an oil shock absorber using working oil as a working fluid, there is provided a hydraulic shock absorber according to an embodiment of the present invention. More specifically, the hydraulic damper according to the embodiment of the present invention can be used in a horizontal position, and is a so-called one-way flow type hydraulic damper in which hydraulic oil flows in only one direction. It can be used as a deflection shock absorber and left and right dynamic shock absorber for trolleys such as railway vehicles. Moreover, in the following introduction, for the convenience of introduction, the right side in the figure is taken as one end side, and the left side in the figure is taken as the other end side.

[0023] First, according to Figure 1~3 The oil shock absorber 1 of the first embodiment of the present invention will be describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com