Adhesive tape dividing and cutting machine with environment protection function

A slitting machine and functional technology, applied in separation methods, dispersed particle filtration, dispersed particle separation, etc., can solve problems such as unfavorable normal operation of slitting machine, discomfort of staff, unfavorable environmental protection, etc. Sex, the effect of avoiding discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

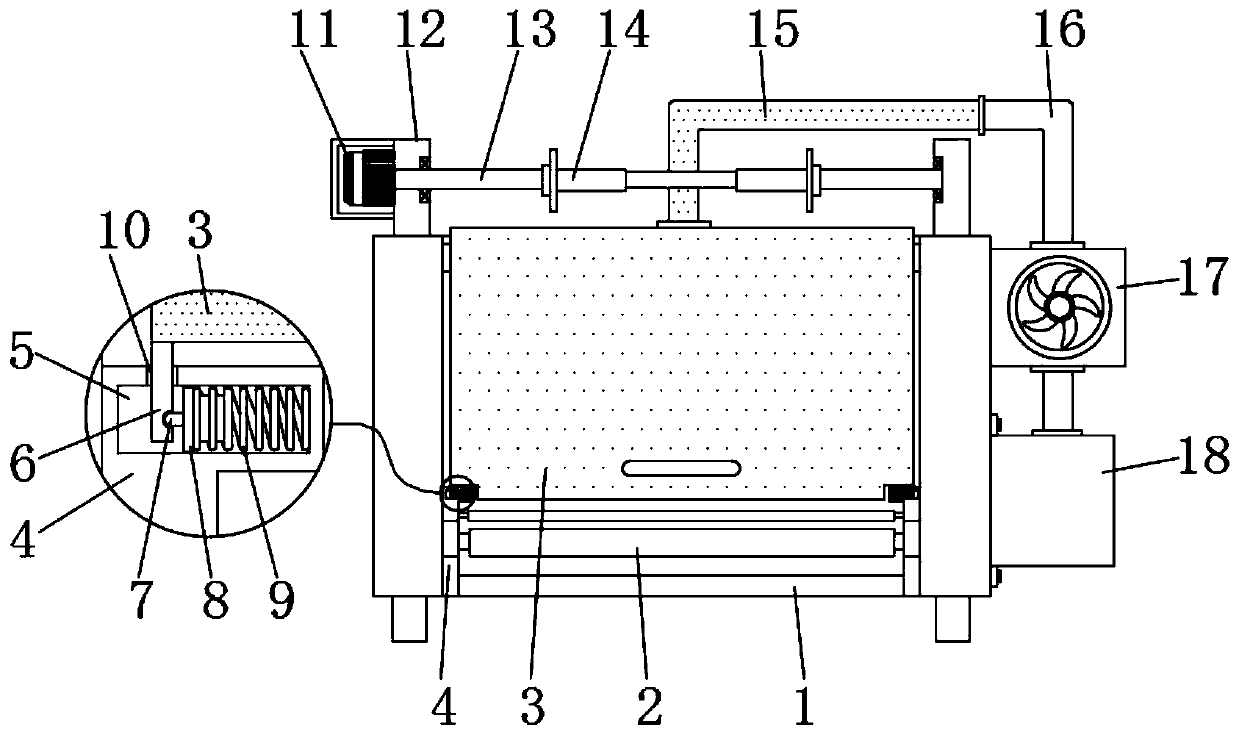

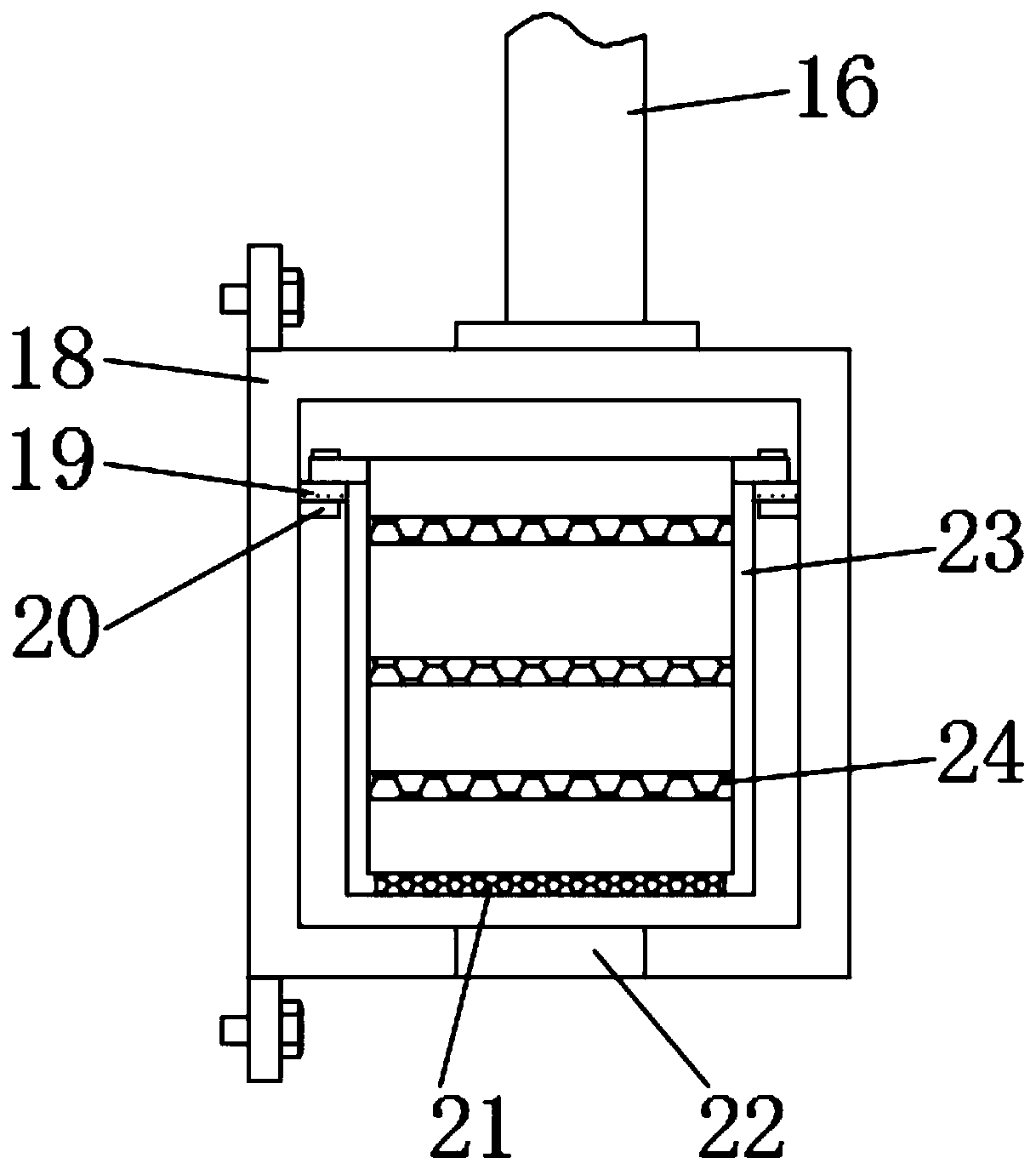

[0026] Embodiment one, with reference to figure 1 and figure 2 , an adhesive tape slitting machine with environmental protection function, comprising a slitting machine body 1, two supporting plates 4 are symmetrically welded on one side surface of the lower part of the slitting machine body 1, and a feeding device is installed between the two supporting plates 4 The upper part of the roller 2 and the support plate 4 is connected with the cover 3 through hinge rotation, and the middle position of the top surface of the cover 3 is connected with the hose 15, and the side surface of the slitting machine body 1 is fixed with an air filter box 18. And the top surface of the air filter box 18 is connected with an air guide pipe 16, and one end of the air guide pipe 16 is connected with the flexible pipe 15, and the surface of the air guide pipe 16 is equipped with a suction fan 17, and the inner wall of the air filter box 18 is welded with a frame 20 , and the top surface of the ...

Embodiment 2

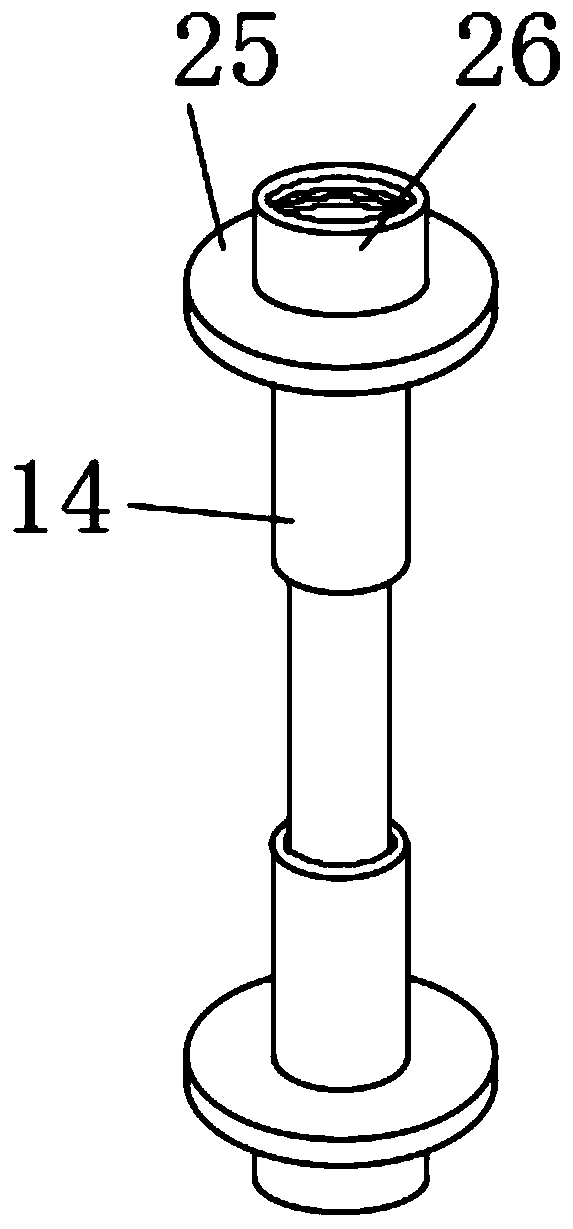

[0027] Embodiment two, refer to figure 1 and image 3The top surface of the slitting machine body 1 is symmetrically welded with two baffles 12, and the opposite surfaces of the two baffles 12 are connected with a winding rod 13 through bearing rotation, and a motor 11 is installed on the surface of one of the baffles 12, And the output end of the motor 11 runs through the baffle plate 12 and is connected to the winding rod 13 in rotation. A telescopic rod 14 is arranged between the winding rods 13 of the two baffle plates 12, and the two ends of the telescopic rod 14 are welded with a stopper 25. The surface of the disc 25 is welded with a threaded sleeve 26 corresponding to the winding rod 13, and one end of the winding rod 13 is provided with an external thread corresponding to the threaded sleeve 26. It is composed of two sleeves and a sleeve rod. The two ends of the sleeve rod are nested in the two sleeves. One end of the two sleeves is welded with a set of stop discs 25...

Embodiment 3

[0028] Embodiment three, refer to figure 1 and Figure 4 , the inner upper part of the two support plates 4 is provided with an inner cavity 5, and a spring 9 is installed in the inner cavity 5, and one end of the spring 9 is sleeved with an abutment column 8, and one end of the abutment column 8 is welded with a convex column 7 , and the top of the boss 7 is located on the top surface of the support plate 4 to open a relief opening 10, the relief opening 10 penetrates the inner cavity 5, and the bottom edge of the casing 3 is welded with a locking plate 6 corresponding to the two support plates 4, and One end of the locking plate 6 extends through the relief opening 10 to the inner cavity 5, a sliding cavity 27 is provided on one side surface of the locking plate 6, and an arc-shaped groove 28 is provided at one end of the sliding cavity 27 corresponding to the boss 7, and the locking plate 6 The side inserted into the inner cavity 5 is a smooth slope, the lower surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com