Knapsack traveling automatic fertilizer spreader

A piggyback and automatic technology, applied in the field of agricultural machinery, can solve the problems of labor-intensive and time-consuming, no fertilization machinery, etc., to achieve good fertilization effect, reduce energy consumption, and reduce hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

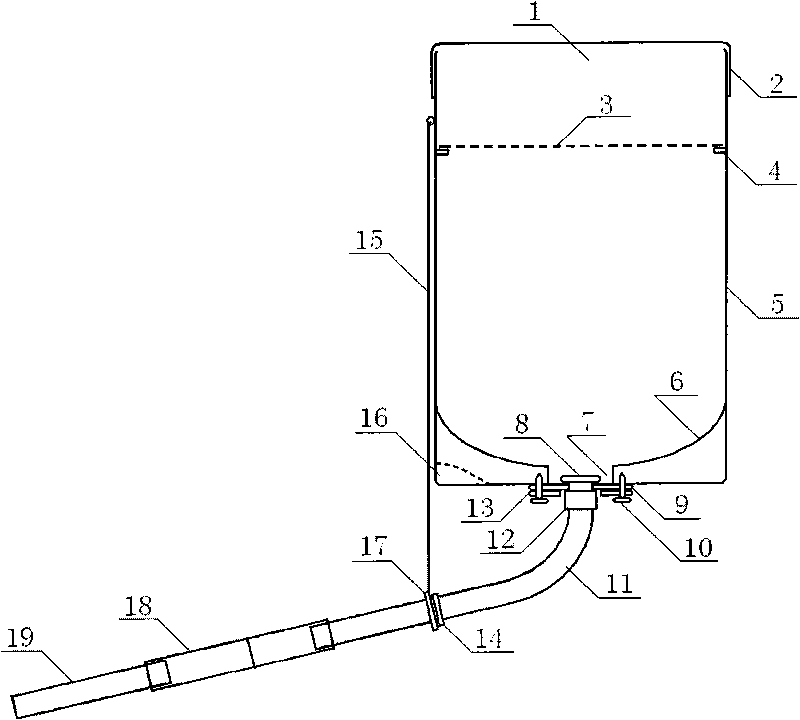

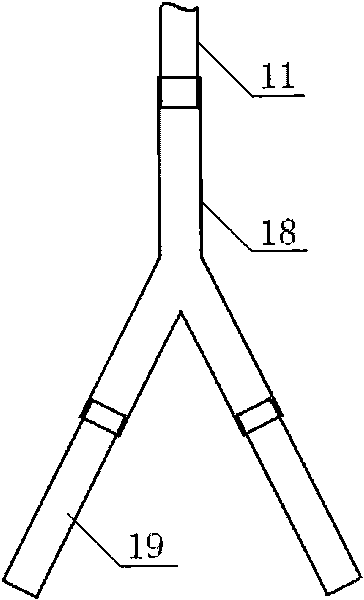

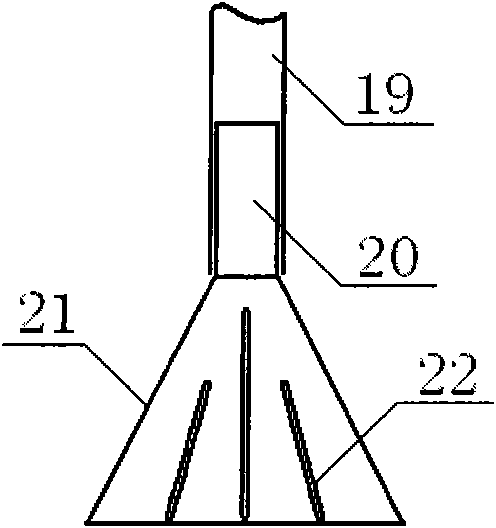

[0021] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, the material barrel 5 can be set to be similar to the sprayer cylindrical shape, and is provided with a strap (on the same side as the feed pipe 11, not shown in the figure), which is carried by the operator. The upper part of the material barrel 5 is an open structure, forming The bucket mouth 1 is provided with a bung 2 on the bucket mouth 1, which can prevent the volatilization of the fertilizer, and can prevent rainwater from falling into the bucket 5 while fertilizing while raining; Grid frame 4 is arranged, and filter screen 3 is placed on the scaffolding on grid frame 4, and filter screen 3 is used for filtering larger fertilizer block, to prevent clogging; The lowest part is the bottom hole 7 opened at the bottom of the material barrel 5, so that the lower part of the whole material barrel 5 becomes funnel-shaped, which is convenient for the fertilizer to flow to the bottom hole 7; In the part on the ...

Embodiment 2

[0025] Embodiment 2: as Figure 4As shown, the top of the material barrel 5 is provided with a material barrel mouth 1. Compared with Embodiment 1, the material barrel mouth 1 is relatively small, and the bottom of the material barrel 5 is provided with a concave bottom 23, which is convenient for the flexible holder described in Embodiment 1. Placed therein, it is convenient for the material bucket 5 to be placed on the ground; a card slot 16 is provided on one side of the material bucket 5 . In this figure, when the pull wire ring 17 moves forward to make the feed pipe 11 rise, the upper nozzle of the feed pipe 11 is inclined, and the fertilizer no longer enters the feed pipe 11 smoothly; at the same time, the lower raised feed pipe 11 , It also plays a certain role in hindering the flow of fertilizer, so that the fertilizer no longer flows. Like this, lifting feed pipe 11 has played the effect of spraying fertilizer switch. The rest of the structure is the same as that of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com