Straw collecting and pulverizing device of corn harvester

A corn harvester and crushing device technology, which is applied to harvesters, crop processors, agricultural machinery and implements, etc., can solve the problems of harvesting equipment center of gravity deviation and high manufacturing cost, and achieve reasonable and compact structure, low cost, and power machine center of gravity balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

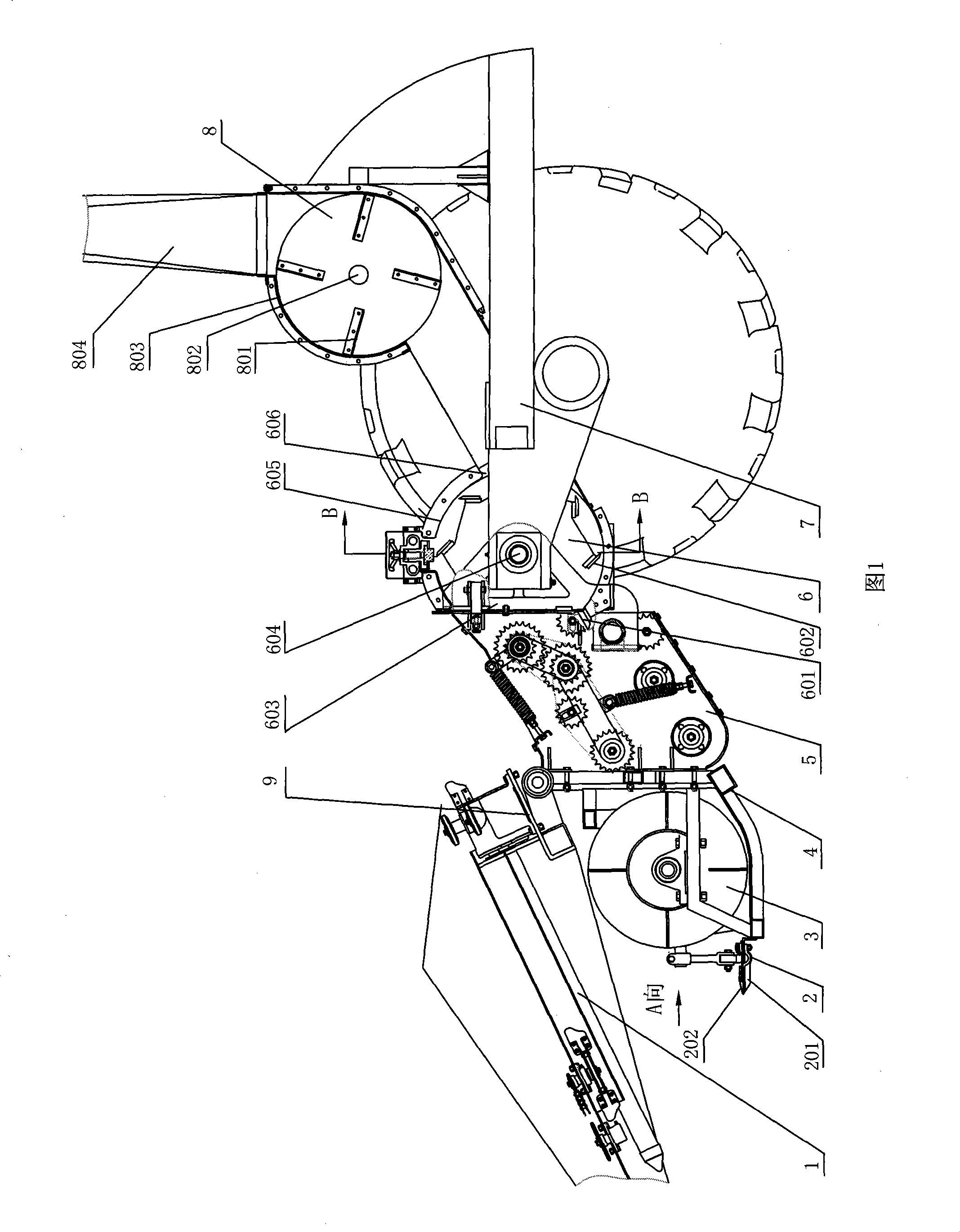

[0021] exist figure 1 Among them, a corn harvester straw collecting and pulverizing device includes a straw cutter 2, the straw cutter 2 is the front end of the fixing frame 4 installed under the ear picking roller 1 and connected with the header fixing frame 9, It is composed of a fixed knife 201 and a movable knife 202, and realizes the reciprocating shearing motion through the power transmission component, which can cut off the root of the corn stalk.

[0022] like figure 1 As shown, a corn harvester straw collecting and pulverizing device further includes a straw collector 3 , and the straw collector 3 is supported and installed at the rear end of the fixed frame 4 by a bearing corresponding to the straw cutter 2 .

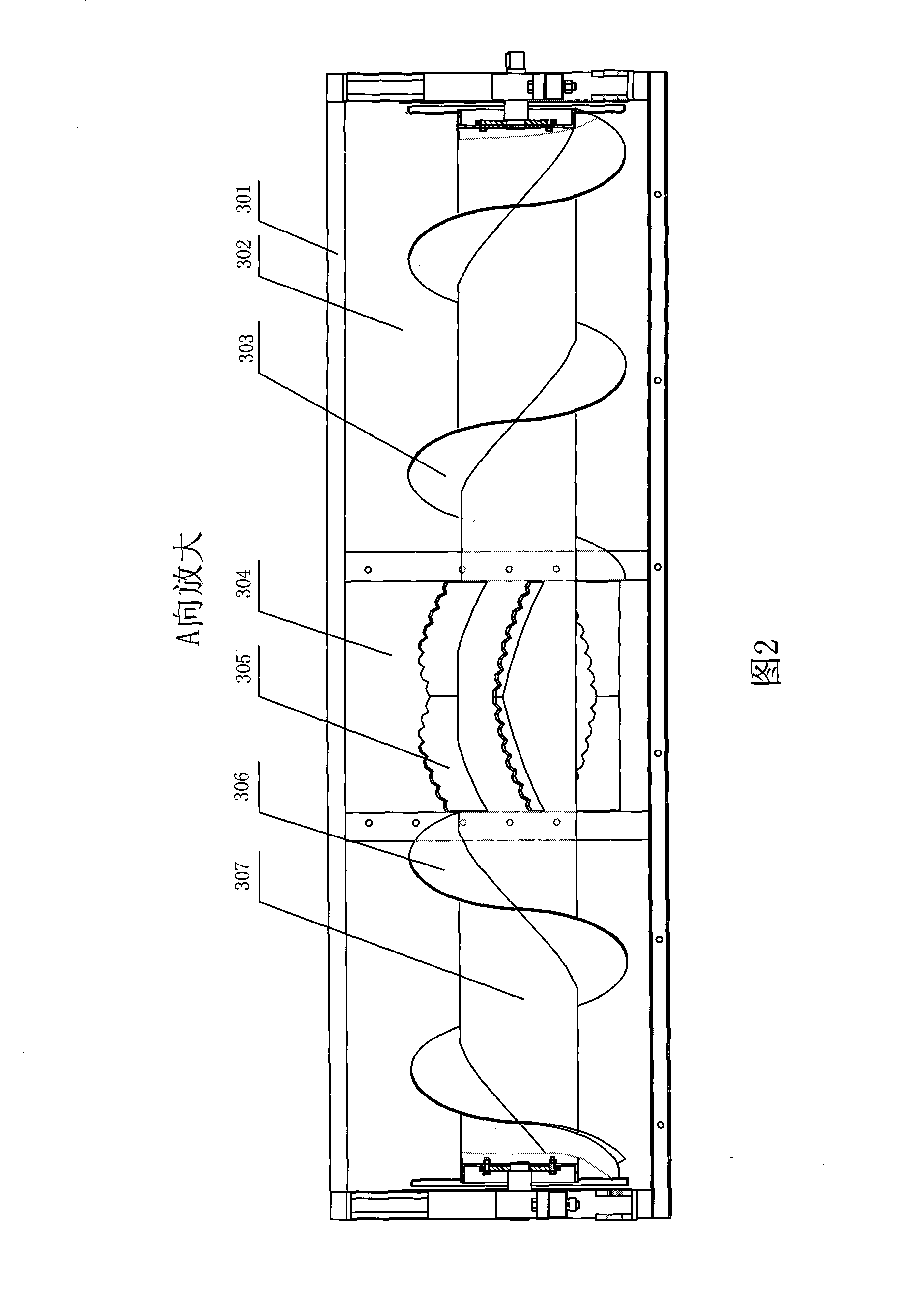

[0023] like figure 2 As shown, the straw collector 3 is composed of a cylindrical shell 301 and a rotating roller 307 rotatably supported on the shell. The cylindrical shell 301 is provided with a feeding port 302 and a feeding port 304. The rotating rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com