Tube expander

A tube expander and tube expansion technology, which is applied to heat exchange equipment and other directions, can solve problems such as troublesomeness and low alignment accuracy, and achieve the effects of high adjustment accuracy, fast adjustment speed and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

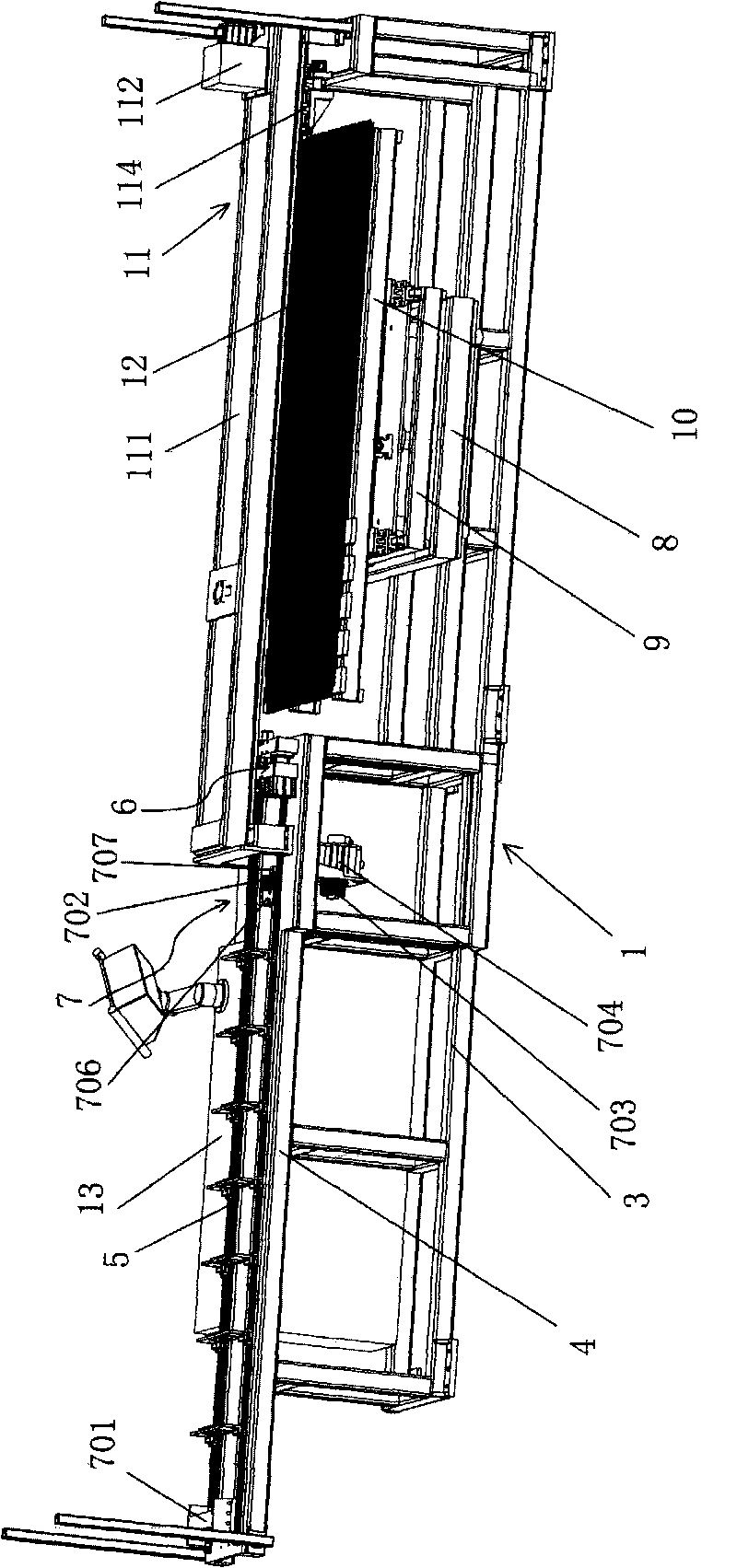

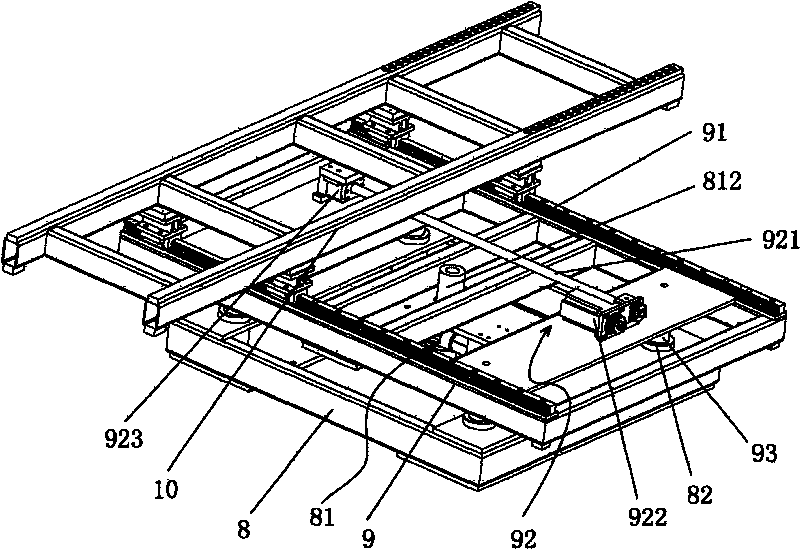

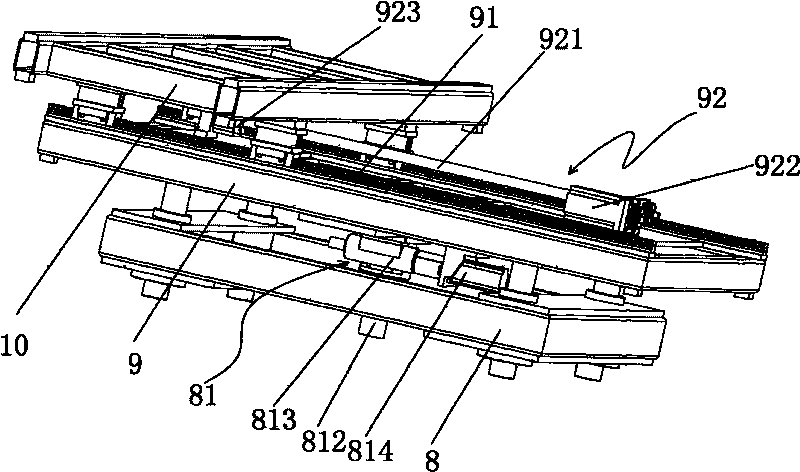

[0023] tube expander, such as figure 1 As shown, it is used to expand the metal tube of the heat exchanger 12 so that it is closely combined with the heat exchange fins to achieve a good heat conduction effect. The tube expander includes a body 1 and a control system 13 connected to the body 1, and the control system 13 is used to control the action of the whole tube expander.

[0024] Such as figure 1 , 5 As shown in . 5. The expansion rod 5 is a slender rod, and the end of the expansion rod 5 close to the clamping device 6 is provided with an expansion ball head. One end of the main frame 4 close to the workbench 2 is provided with a clamping device 6 , and the other end is provided with a push mechanism 7 for pushing the expansion rod 5 to slide. The clamping device 6 is provided with a plurality of expansion collets 604 through which the expansion rod 5 can pass.

[0025] Such as Figure 5 , 6 As shown, the pushing mechanism 7 includes a movable push plate 701 conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com