Non-contact type on-line measurement device and method of large-size bearing roller way

A bearing raceway and measuring device technology, applied in the field of measurement, can solve the problems of large measurement error, clamping processing, unfavorable and timely correction, etc., to achieve the effect of improving accuracy and efficiency, meeting measurement requirements, and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] In this embodiment, the bearing to be tested is a double-row bearing with an inner diameter of 1900 mm, an outer diameter of 2250 mm, a bearing thickness of 300 mm, a raceway pitch of 140 mm, and a raceway section circle diameter of 80 mm.

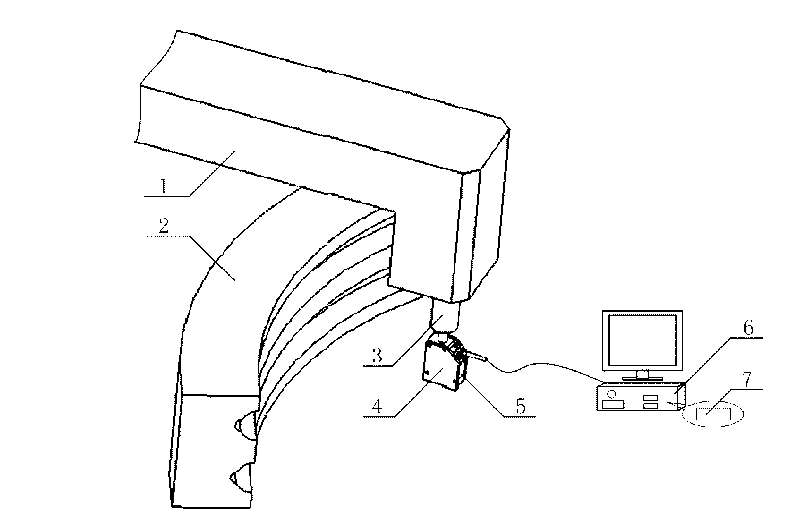

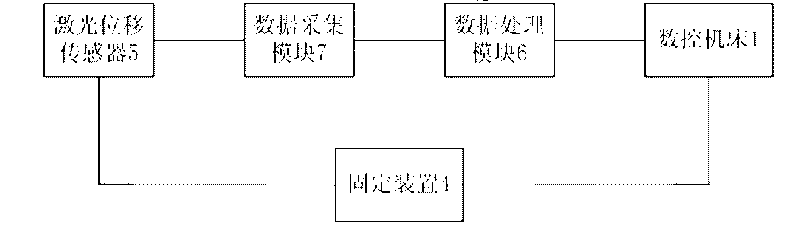

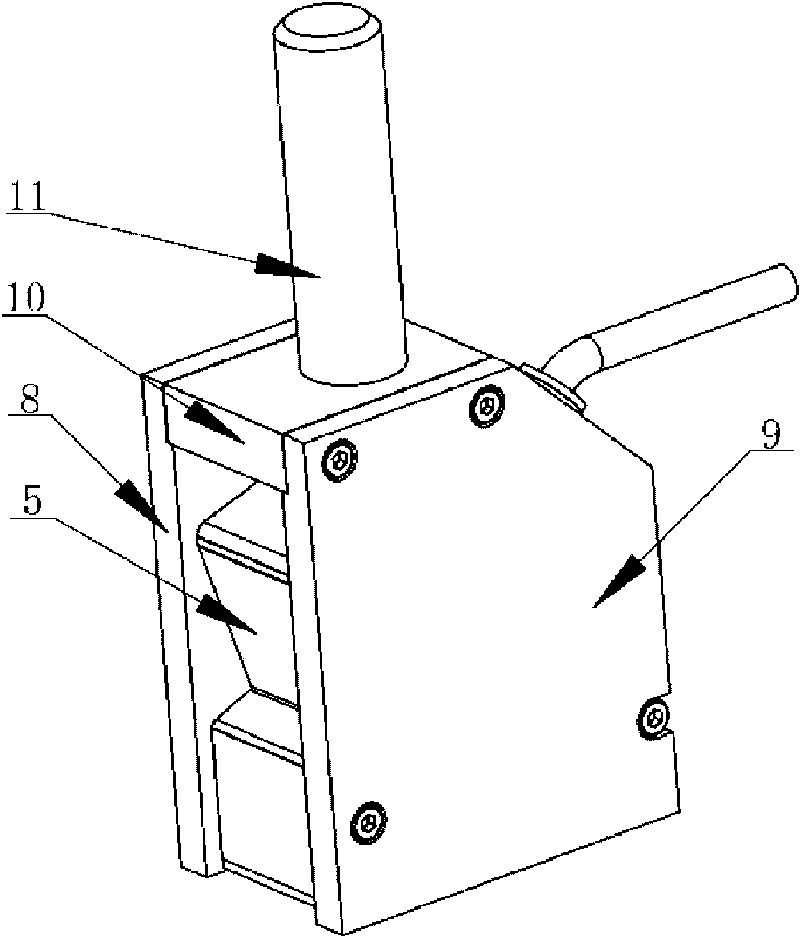

[0025] Such as figure 1 and figure 2 As shown, the non-contact on-line measurement device of the large-scale bearing raceway involved in this embodiment includes: a fixing device 4, a laser displacement sensor 5, a data processing module 6, and a data acquisition module 7, wherein: the laser displacement sensor 4 and the data acquisition module The module 6 is connected to transmit the distance point series data of the measured workpiece, the data acquisition module 7 is connected to the data processing module 6 to transmit the distance point series data of the bearing sleeve section, and the data processing module 6 cooperates with the vertical movement of the CNC machine tool 1 spindle to obtain the CNC machine tool holder 3 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com