Laser hot pressing lay-up forming device for thermoplastic composite material sheet

A composite material and molding device technology, applied in the field of laser manufacturing equipment, can solve the problems of unfavorable light weight, different thickness of glue, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 A laser hot-press lay-up molding device for a thermoplastic composite material sheet.

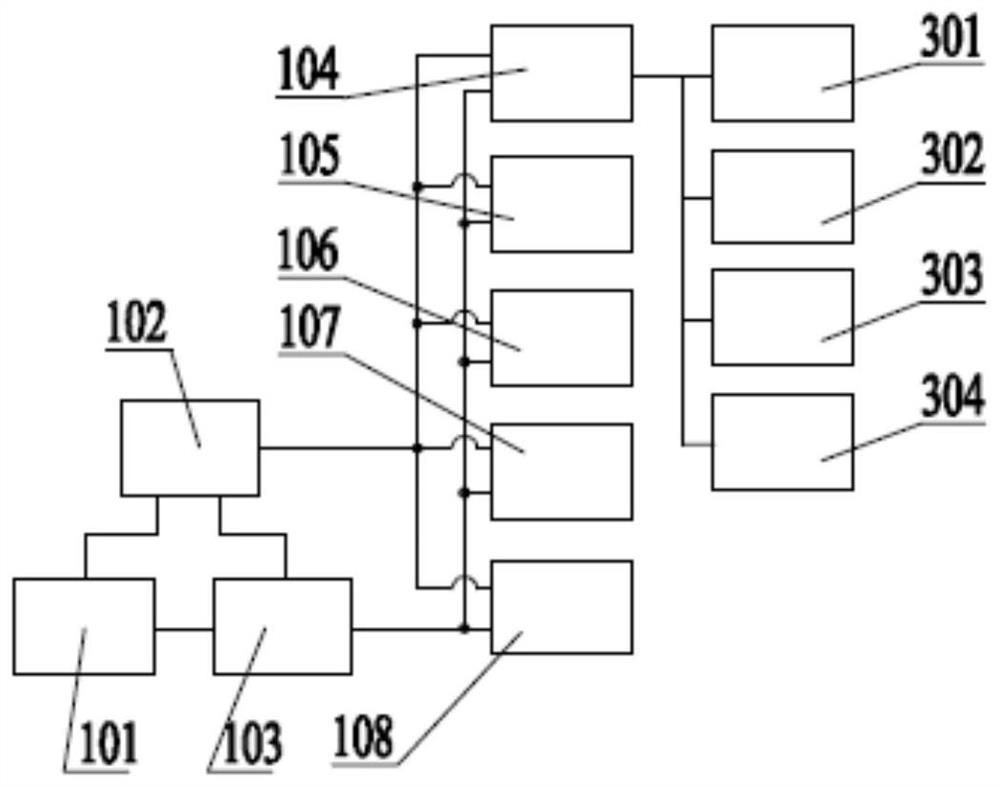

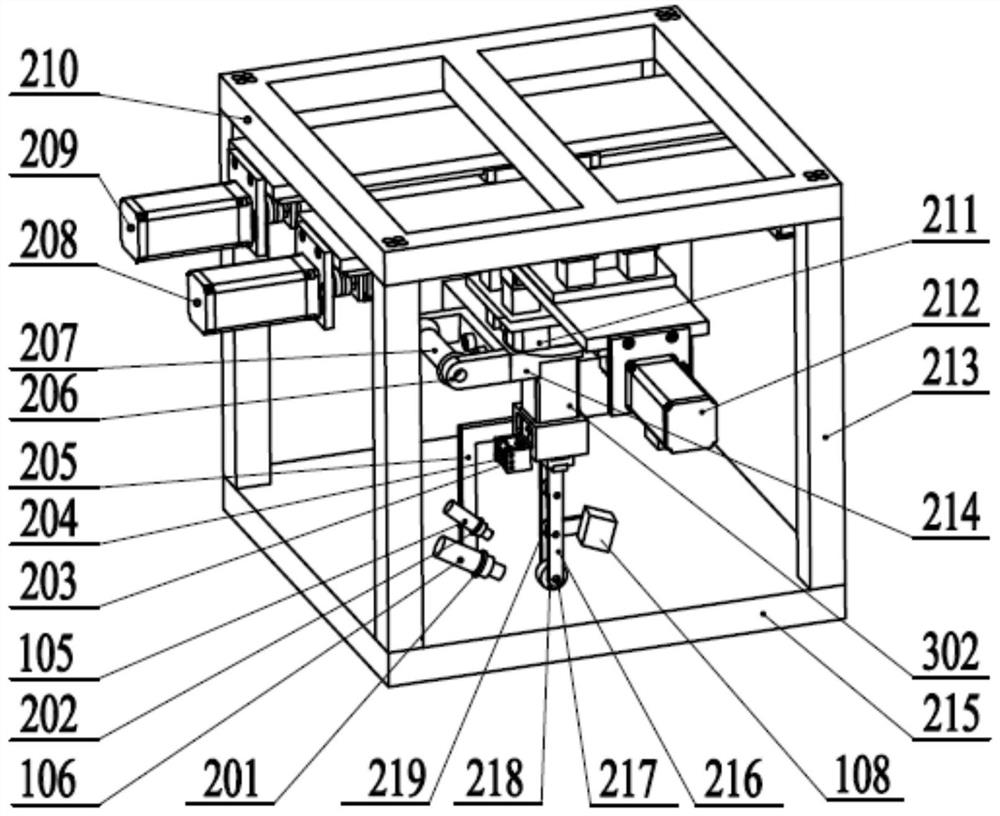

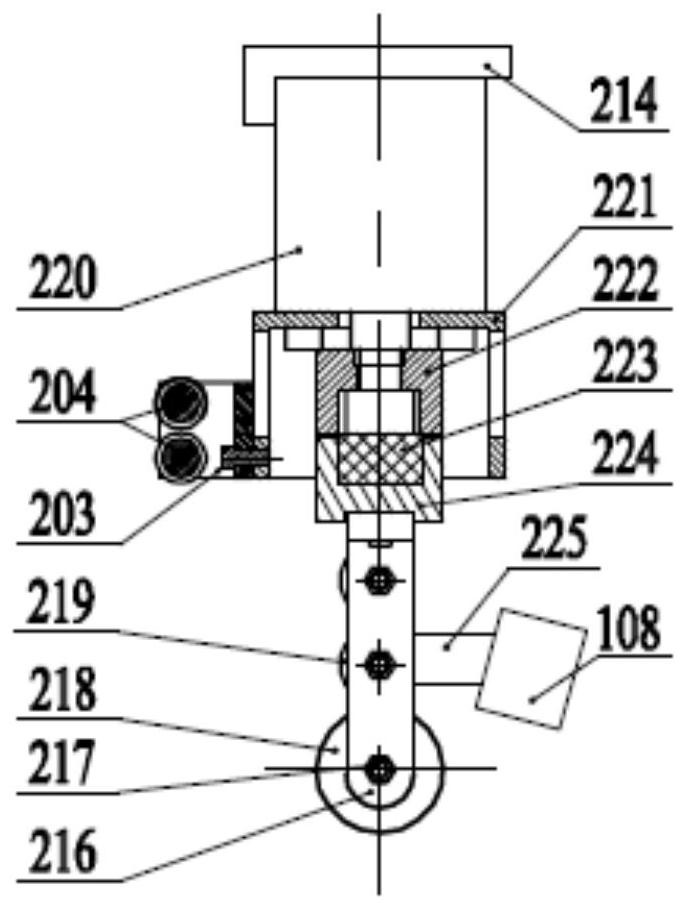

[0024] as attached figure 1 As shown, the present invention provides a thermoplastic composite sheet material laser hot pressing laying forming device, including a host computer 101, a power module 102, a control unit 103, a hydraulic unit 104, a temperature acquisition unit 105, a laser heating unit 106, a laying Platform 107 and curing degree measuring unit 108; the operator sets parameters such as laying trajectory, heating temperature, curing degree and laying pressure on the host computer 101, and sends control instructions to the control unit 103, and the power module 102 sends control instructions to the host computer 101 , the control unit 103, the hydraulic unit 104, the temperature acquisition unit 105, the laser heating unit 106, the laying platform 107 and the curing degree measurement unit 108 are powered, and the control unit 103 realizes the hydraulic unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com