Device and method for detecting wheel diameter of urban rail vehicle with sensor arc vertically installed

A vertical installation, urban rail vehicle technology, applied in the direction of rim measurement/measurement, can solve the problems of low measurement accuracy, slow measurement response speed, difficult engineering implementation, etc., to achieve high measurement accuracy, fast detection speed, and large measurement range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

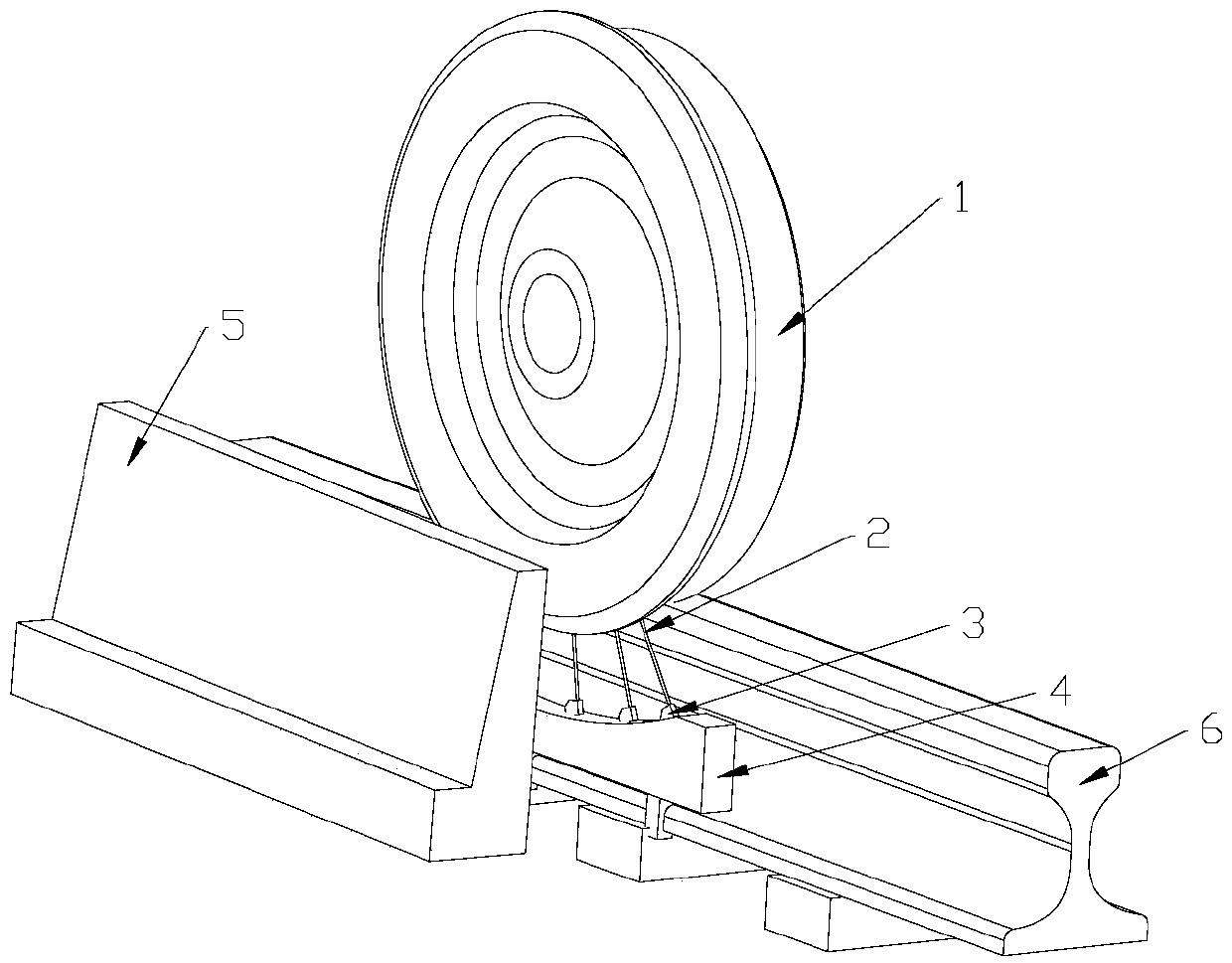

[0054] This embodiment is a device and method for detecting the wheel diameter of an urban rail vehicle in which the sensor arc is installed vertically.

[0055] Such as Figure 5 As shown, the probes of n laser sensors are arranged along the direction of the rail and evenly distributed on an arc with a chord length of L and a radius of R, and the detection beams of each laser sensor are vertical to the rail.

[0056] The external factors that affect the accuracy of the laser triangulation sensor mainly include the tilt of the measured surface, surface gloss, roughness, color, and scanning speed. The sensor adopts arc normal installation, so that the laser sensor probe can be aligned with the measured surface at the same time, effectively suppressing the error caused by the inclination of the measured surface; at the same time, it is conducive to the analysis of the optimization process of the installation parameters and reduces the difficulty of analysis.

[0057] The instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com