On-line non-contact measurement method for straightness of shaft parts

A technology for non-contact measurement and shaft parts, which is used in measurement devices, instruments, optical devices, etc., to achieve the effect of improving measurement speed, high measurement accuracy and measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

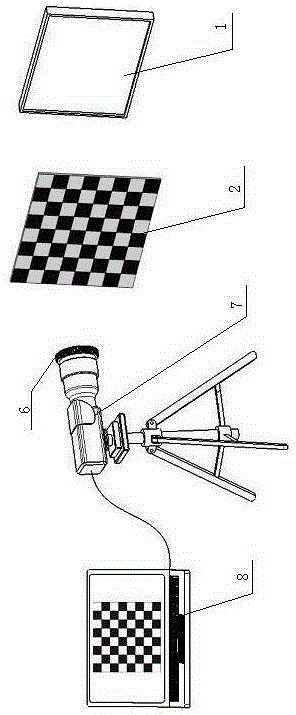

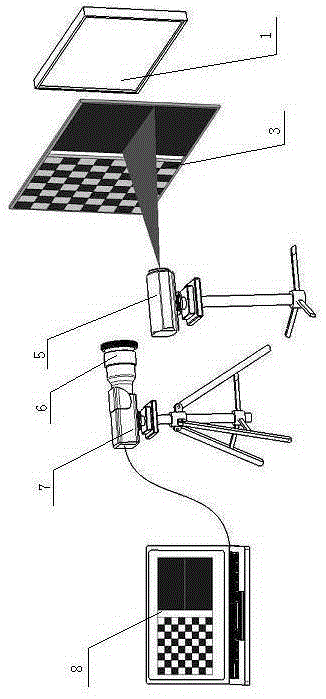

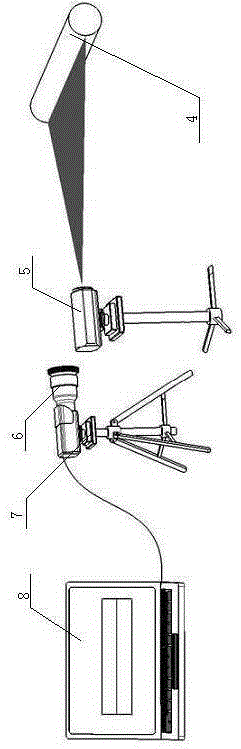

[0051] see figure 1 , the online non-contact measurement method for the straightness of shaft parts of the present invention, based on the structured light visual imaging system, establishes the measurement model of the straightness of shafts, and combines the light bar center line detection technology of line structured light, corner point detection technology and camera calibration Technology, etc. to realize the measurement of the straightness of the measured shaft, which includes the following steps:

[0052] 1. Calibrate the internal parameters and distortion coefficients of the CCD camera. Based on the camera plane calibration algorithm proposed by Zhang Zhengyou, the internal parameters of the camera and the distortion coefficient of the lens are calibrated by using the corner coordinates of the images of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com