On-line Measuring Method of Diameter of Shaft Parts Using Conic Invariants

A technology for quadratic curves and shaft parts, applied to measuring devices, optical devices, instruments, etc., to achieve high measurement accuracy, high measurement speed, and correction of distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

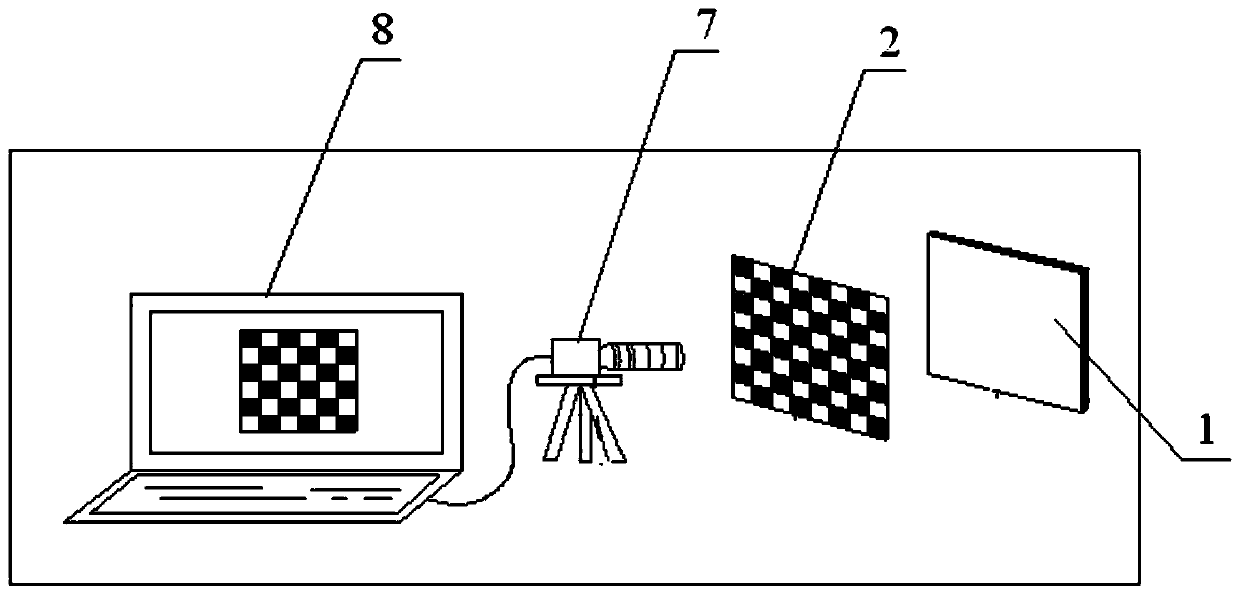

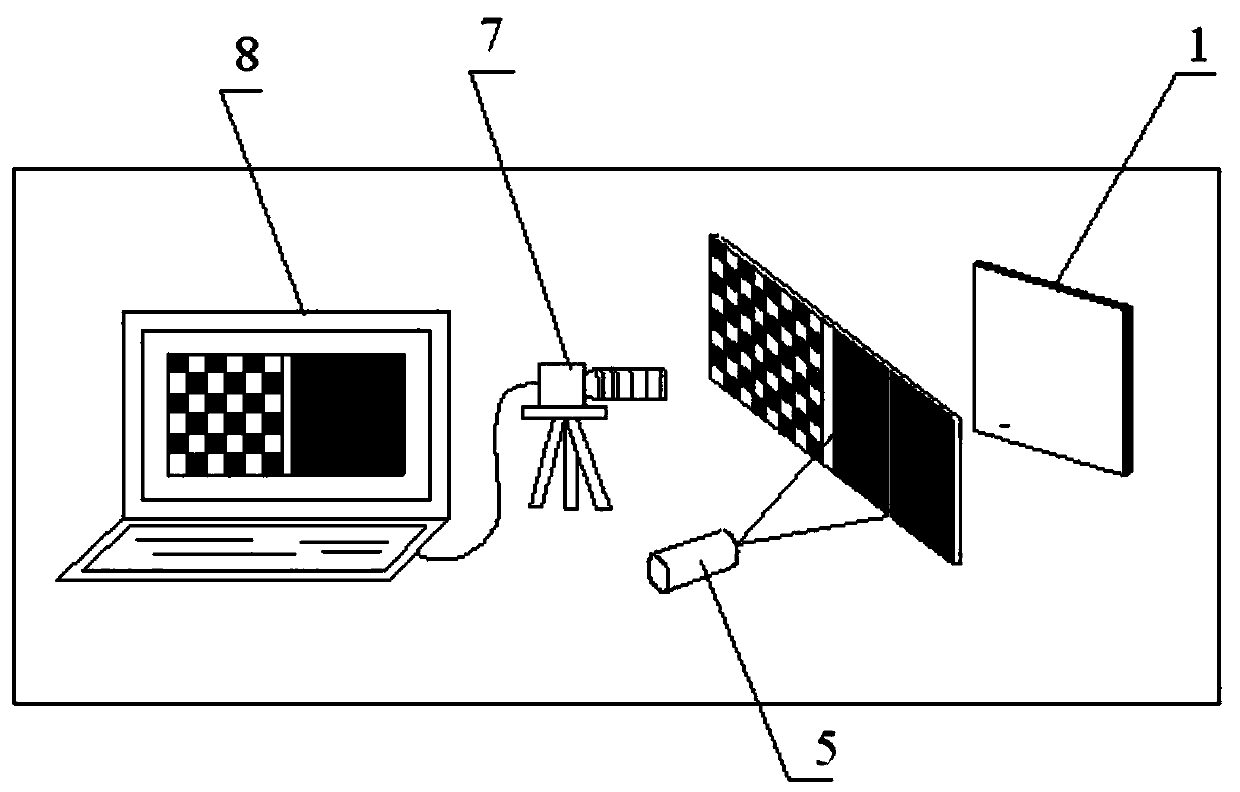

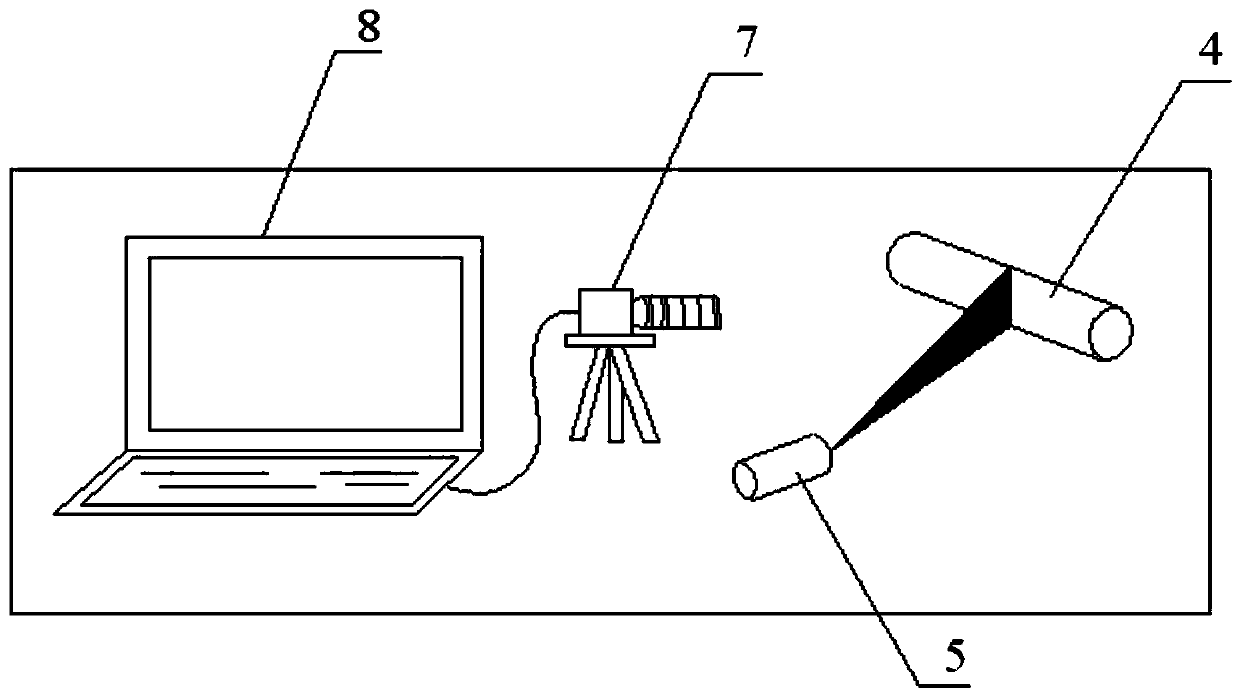

[0040] see Figure 1 to Figure 6 Shown:

[0041] The on-line measurement method for the diameter of shaft parts using the quadratic curve invariant provided by the present invention is as follows:

[0042] Step 1. Calibrate the internal parameters and distortion coefficients of the CCD camera. Based on the camera plane calibration algorithm proposed by Zhang Zhengyou, use the high-precision calibration board to calibrate the corner coordinates of the images in different postures to calibrate the internal parameters of the camera and the distortion coefficient of the lens. The specific process includes Follow these steps:

[0043] 1) Using the CCD camera 7 to collect nine images of the calibration board in different attitudes. When collecting images, the positional relationship between the backlight 1, the calibration plate 2 and the CCD camera 7 is as follows: figure 1 As shown, the nine calibration board images collected are as follows: Figure 4 shown;

[0044] 2), usin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com