Device and method for detecting wheel diameter of urban rail vehicles with sensors installed in a straight line and inclined

A technology for urban rail vehicles and a detection method, which is applied in the direction of rim measurement/measurement, can solve the problems of low measurement accuracy, slow measurement response speed, and difficult engineering implementation, and achieves high measurement accuracy, fast detection speed, and large measurement range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

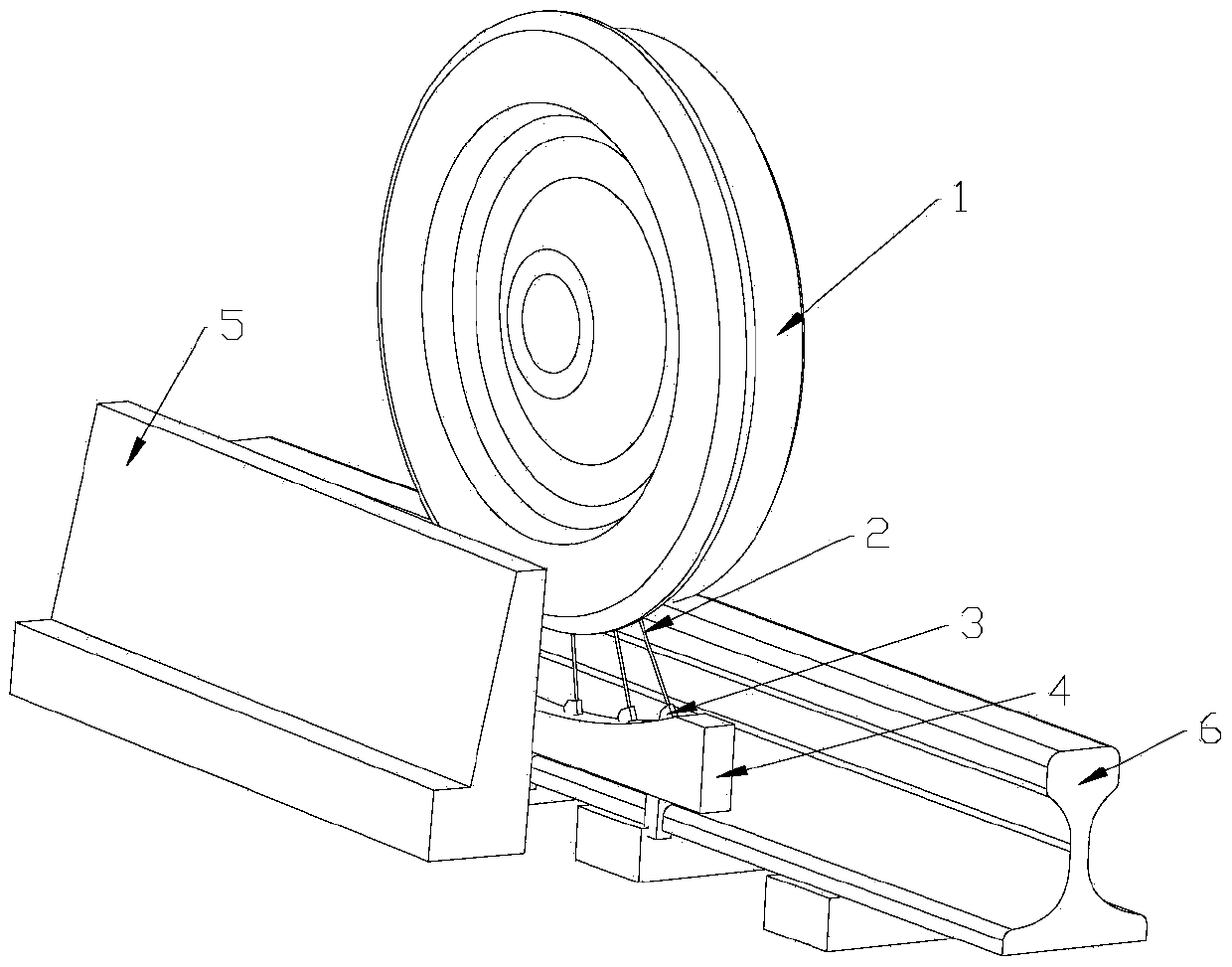

[0052] This embodiment is a device and method for detecting the wheel diameter of an urban rail vehicle in which the sensor is installed linearly and obliquely.

[0053] Such as Figure 5 As shown in , the probes of the laser sensors are arranged along the direction of the rail and evenly distributed on the horizontal line with a length of L, and the installation inclination angle θ of each laser sensor probe relative to the X-axis is set according to the coordinates of the laser sensor i , so that the laser sensor probes measure along different directions and the detection beams can reach the wheel at the same time.

[0054] The installation parameters of the laser sensor meet the following conditions: the number of laser sensors is n and 3≤n≤10, the length of the laser sensor installation horizontal line is E and n×30mm≤L≤1800mm, the installation point of the first laser sensor along the direction of the rail The vertical distance to the orbit is |y 1 |and|y 1 |≥100mm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com