Trimming fixture

A technology for trimming burrs and jigs, which is applied in the field of jigs for repairing burrs of molded products. It can solve the problems of time-consuming and labor-intensive repairing of burrs, and reduce product output, so as to improve repair speed and save manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the above and other objects, features, and advantages of the present invention more comprehensible, some embodiments are specifically cited below and described in detail in conjunction with the accompanying drawings.

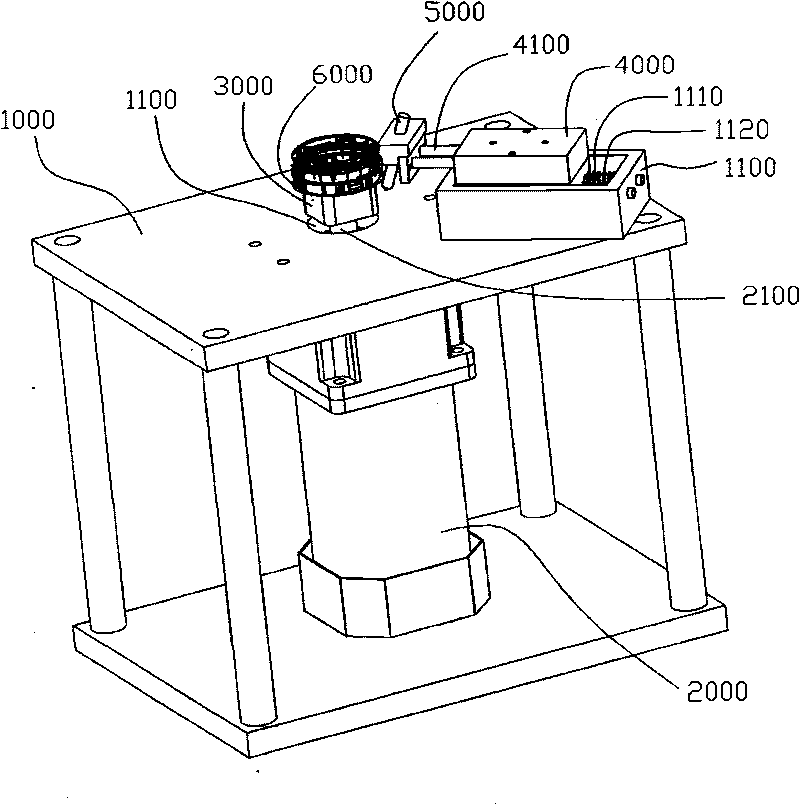

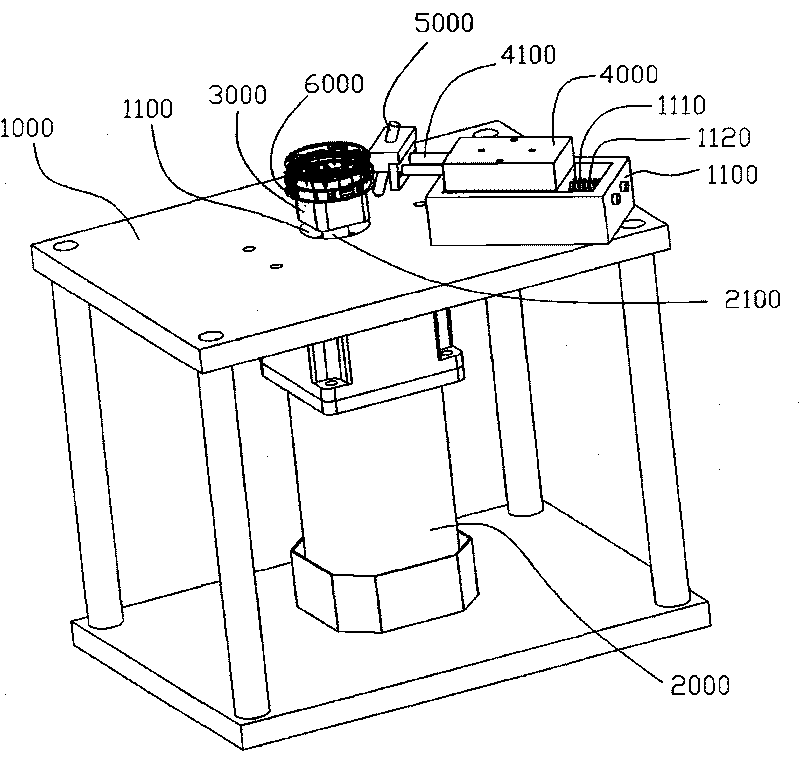

[0011] see figure 1 As shown, the present invention includes a substrate 1000, a motor 2000, a fixed seat 3000, a cylinder 4000, and a burr cutter 5000. In this embodiment, the burr cutter 5000 is a cylindrical cutter, and the burr cutter 5000 is fixed to the piston of the cylinder 4000. At the end of the rod 4100, the substrate 1000 is provided with a through hole 1100, the rotating shaft 2100 of the motor 2000 protrudes from the through hole 1100 and is fixedly connected to the fixing seat 3000, the fixing seat 3000 can be used to socket and fix the product 6000 to be processed, When the piston rod 4100 is stretched, the burr cutter 5000 can touch the burr of the product 6000 .

[0012] The present invention also includes a support fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com