Method and device for automatically conveying and stacking corrugated boards

A corrugated cardboard and automatic stacking technology, which is applied in stacking receiving devices, transportation and packaging, and sending objects, etc., can solve the problems of manual counting, difficulty in popularization and application, and large factory floor space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

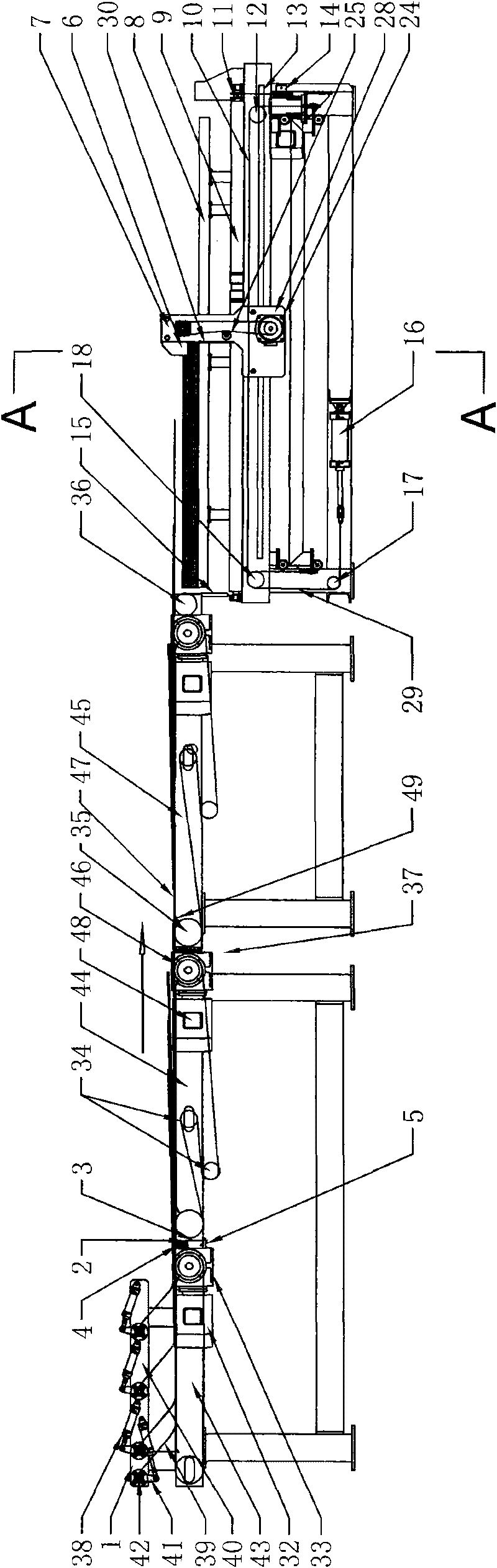

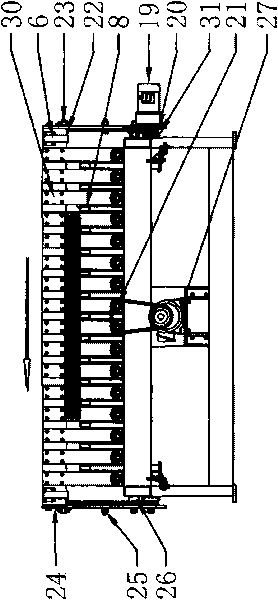

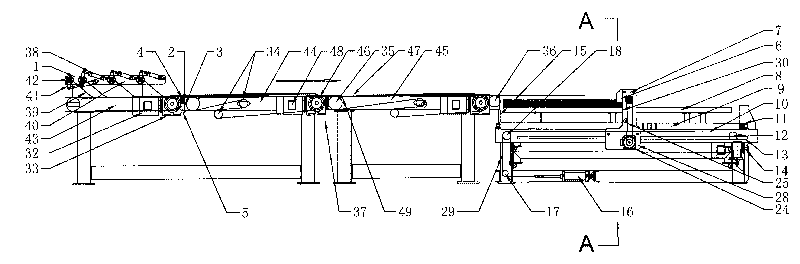

[0017] Attached below figure 1 And attached figure 2 To further illustrate the present invention, a preferred embodiment of the present invention is: the method for automatically stacking corrugated cardboard described in this embodiment, according to the length of the cardboard and the speed of the production line, the press assembly 1 pressurizes the corrugated cardboard in groups, and the platform conveying assembly 37 Self-adaptive conveying speed, so as to ensure that the corrugated cardboard is dislocated neatly and conveyed smoothly. After the corrugated cardboard is pressed by the paper press assembly 1, it is conveyed on the platform conveying assembly 37 into the suspension rail assembly 8, and the suspension rail assembly 8 stops at the initial receiving position driven by the induction cylinder 16 to collect the corrugated cardboard, and the paper stop assembly 7 will enter The corrugated cardboard on the hanging rail assembly 8 is sorted and aligned. When the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com