Fixing structure for transverse stabilizer bar of coach

A technology of stabilizer bars and fixed structures, which is applied to vehicle components, interconnection systems, suspensions, etc., can solve the problems of the space occupied by the stabilizer bars, high requirements for matching dimensions, and increased production costs of parts, so as to save a lot Space, simple fixed structure, and the effect of reducing installation size requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

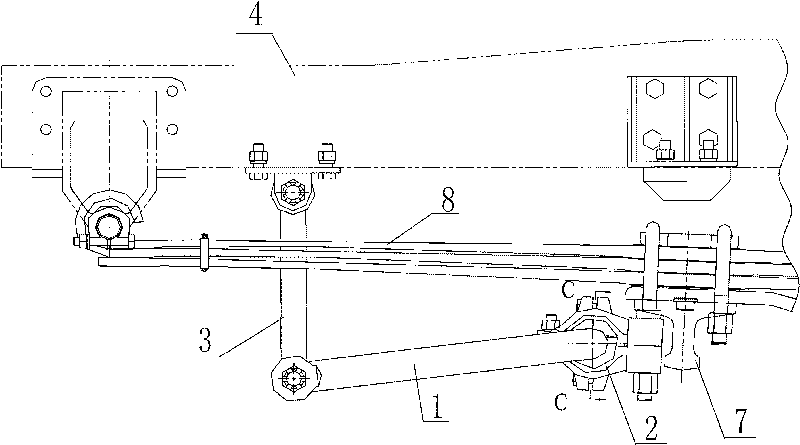

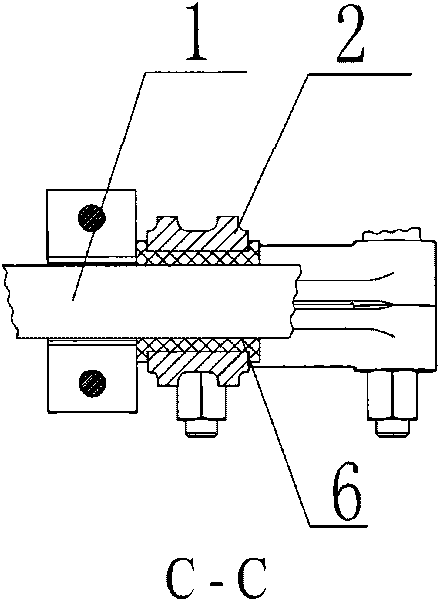

[0014] Embodiment 1: A passenger car stabilizer bar fixing structure, such as figure 1 , figure 2 As shown, the shaft of the stabilizer bar 1 is installed on the front axle I-beam 7 through the fixed bracket 2, and the bent end is hung on the frame longitudinal beam 4 through the suspender 3; the end of the suspender 3 The part is a universal ball joint; a polyurethane bushing 6 is provided between the stabilizer bar 1 and the fixed bracket 2 .

Embodiment 2

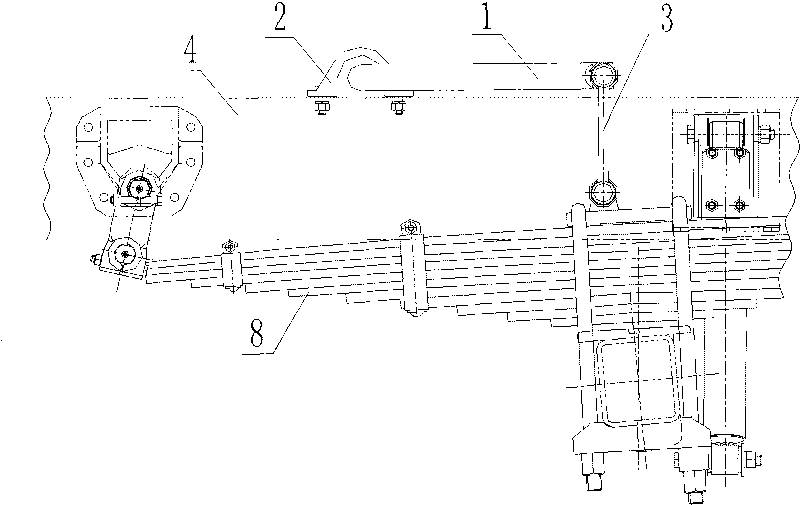

[0015] Embodiment two: a passenger car stabilizer bar fixing structure, such as image 3 As shown, the shaft of the stabilizer bar 1 is installed on the upper surface of the frame longitudinal beam 4 through the fixed bracket 2, and the bent end is connected with the rear axle 5 through the suspension rod 3, the suspension rod fixing frame, the leaf spring 8 and other parts. connection; the end of the boom 3 is a universal ball joint; a polyurethane bushing 6 is provided between the stabilizer bar 1 and the fixed bracket 2 .

[0016] The invention changes the traditional installation method of the lateral stabilizer bar, the fixing structure is simple, and the method is flexible and convenient, which not only ensures that the vehicle body will not have excessive lateral roll when turning, but also reduces the use of supporting parts, saves a lot of space, and reduces the The requirements for the installation size of the two ends of the stabilizer bar are lowered, and the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com