Automobile composite braking system

A compound braking and automotive technology, applied in electric braking systems, electric vehicles, vehicle components, etc., can solve problems such as pressure fluctuations in the master cylinder of the brake, affecting pedal feel, and violent vibration of the brake pedal, and achieve good braking. The effect of pedal feel, low cost combined, and strong dirt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

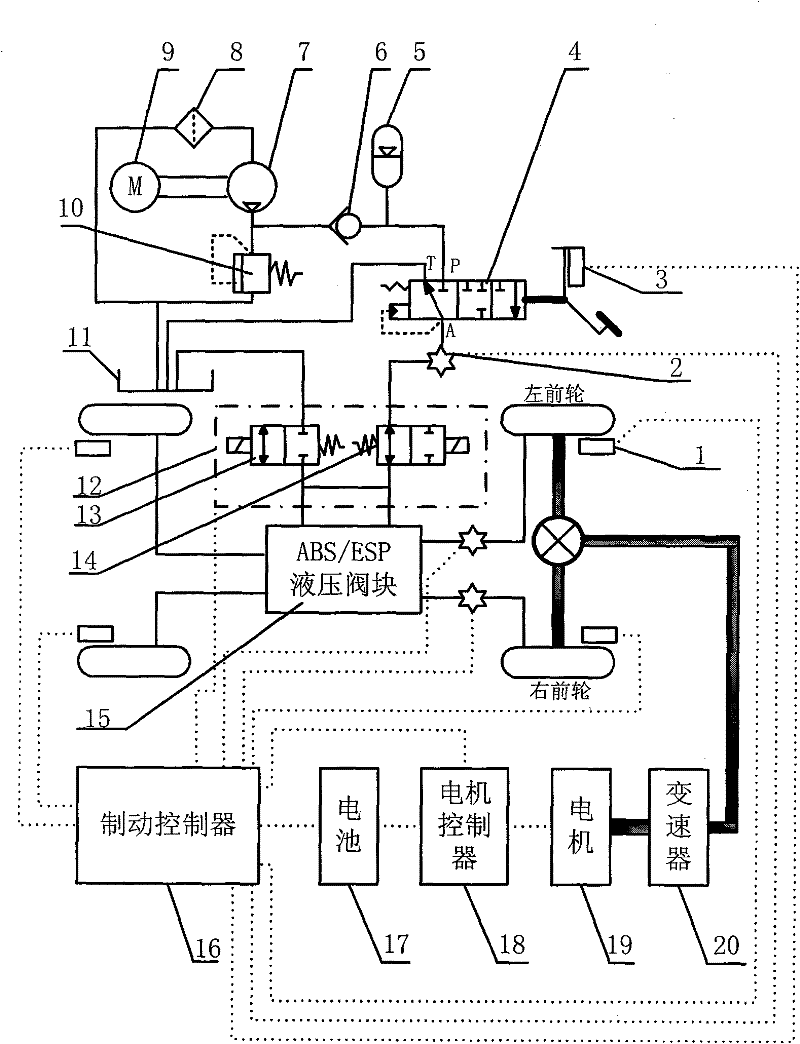

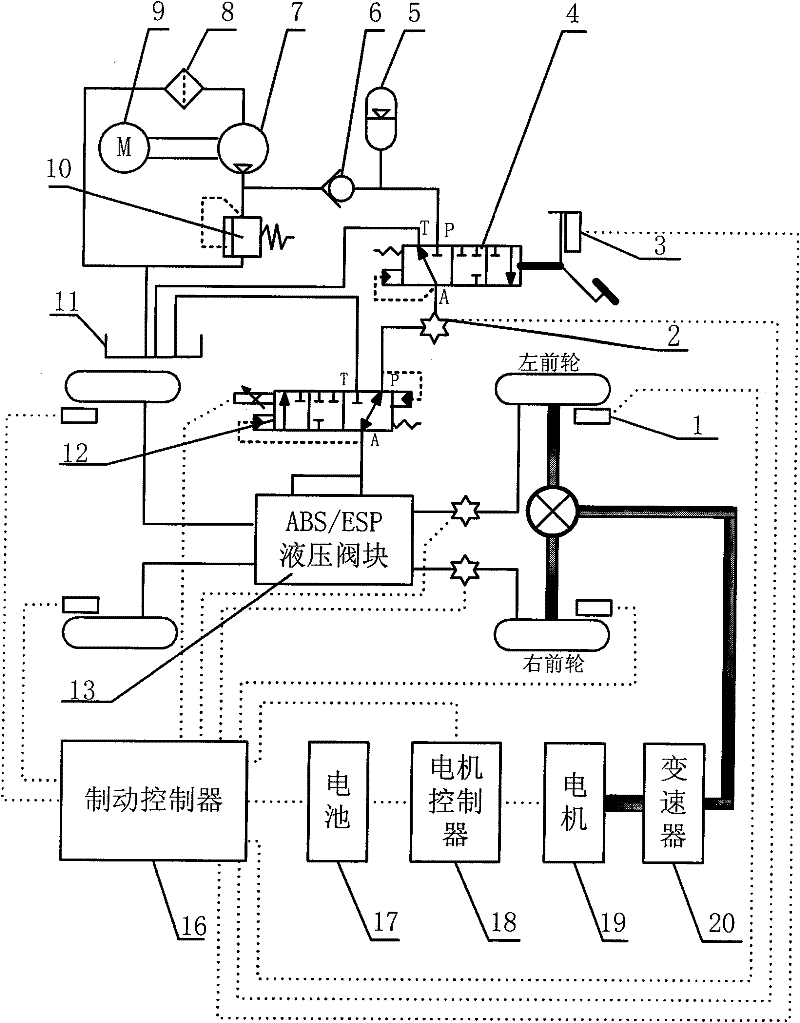

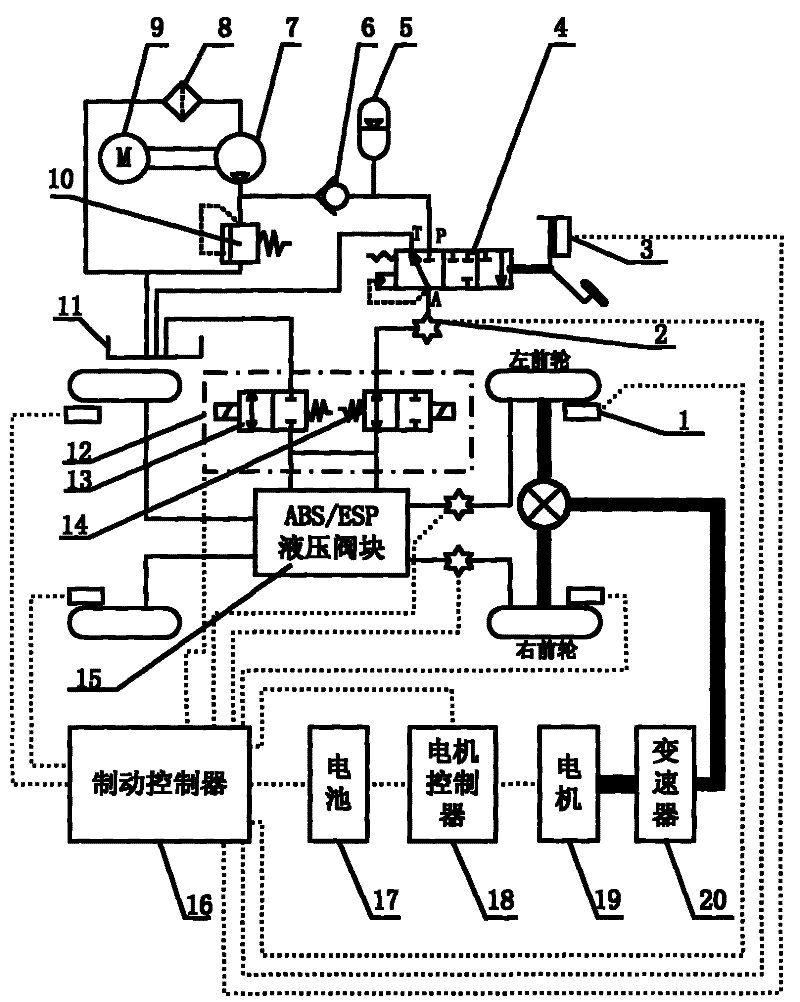

[0016] Such as figure 1 and figure 2 As shown, the composite braking system of the present invention includes a hydraulic braking subsystem and a motor braking subsystem, wherein the motor braking subsystem converts a part of the kinetic energy of the vehicle into electric energy and stores it in the battery through electric power generation, and the insufficient braking force is provided by the hydraulic pressure. brake subsystem provided.

[0017] The hydraulic braking subsystem includes a wheel speed sensor 1, a pressure sensor 2, a brake pedal displacement sensor 3, a pedal brake valve 4, a high pressure accumulator 5, a one-way valve 6, an oil pump 7, a filter 8, a DC motor 9. Relief valve 10, liquid storage tank 11, pressure regulating mechanism 12, ABS / ESP hydraulic valve block 15 and brake controller 16.

[0018] Wherein there are four whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com