Urea formaldehyde slow-release compound fertilizer and preparation method thereof

A slow-release technology for compound fertilizers and urea-formaldehyde, which is applied in the direction of urea compound fertilizers, inorganic fertilizers, fertilizer mixtures, etc., and can solve problems such as no slow-release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

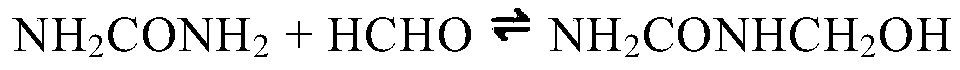

Method used

Image

Examples

Embodiment 1

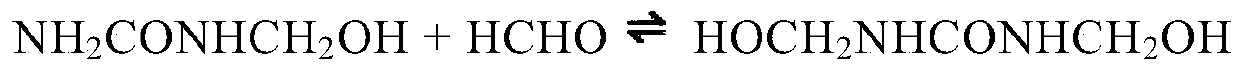

[0105] n(U) / n(F)=1.3:1, and the molar ratio of basic magnesium compound to urea is 1.3:10.

[0106] 1. Addition reaction: Add 1200L of deionized water and 300kg of urea into the reaction kettle, stir, add 27.6kg of magnesium oxide after the urea dissolves, the pH value of the solution is 10.3, then slowly add 35.8kg of concentrated sulfuric acid dropwise, and then add 312kg of formaldehyde solution, The measured pH was 8.5, and the reaction was carried out at 30°C-40°C for 1 hour;

[0107] 2. Condensation reaction: After the addition reaction is over, add 75.0kg of phosphoric acid, the measured pH is 2.5, heat up to 60°C, and react for 1.5h;

[0108] 3. Terminate the condensation reaction: add potassium hydroxide aqueous solution with a concentration of 15.8% (dissolved potassium hydroxide in 5 times of water), adjust the pH value to 8.5, and react at 60°C for 0.5h;

[0109]4. Vacuumize and dehydrate the reactant to obtain a viscous slurry material, send it into a box dryer, ...

Embodiment 2

[0122] n(U) / n(F)=1.4:1, the amount of formaldehyde added was 289.6kg, the reaction temperature of the condensation reaction and the termination condensation reaction were both 55°C, and the other conditions were the same as in Example 1. The pH of the addition reaction is 8.5, and the pH of the condensation reaction is 2.8 to obtain 564.0 kg of urea-formaldehyde slow-release compound fertilizer.

[0123] The measurement result of embodiment 2 is shown in table 3:

[0124] table 3

[0125]

Embodiment 3

[0127] n(U) / n(F)=1.5:1, the amount of formaldehyde added was 270.3kg, and other conditions were the same as in Example 1. The pH of the addition reaction is 8.6, and the pH of the condensation reaction is 3.0 to obtain 563.3 kg of urea-formaldehyde slow-release compound fertilizer.

[0128] The measurement result of embodiment 3 is shown in table 4:

[0129] Table 4

[0130]

[0131] In this embodiment, the AI reaches 62.5%, and the nitrogen release characteristic of the fertilizer is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com