Waste classification plastics collection box

A technology of waste classification and collection boxes, which is applied in the direction of waste collection and transfer, garbage collection, household appliances, etc., which can solve the problems of infiltration, unusable garbage can structure, stench, etc., and achieve the effect of preventing the emission of peculiar smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

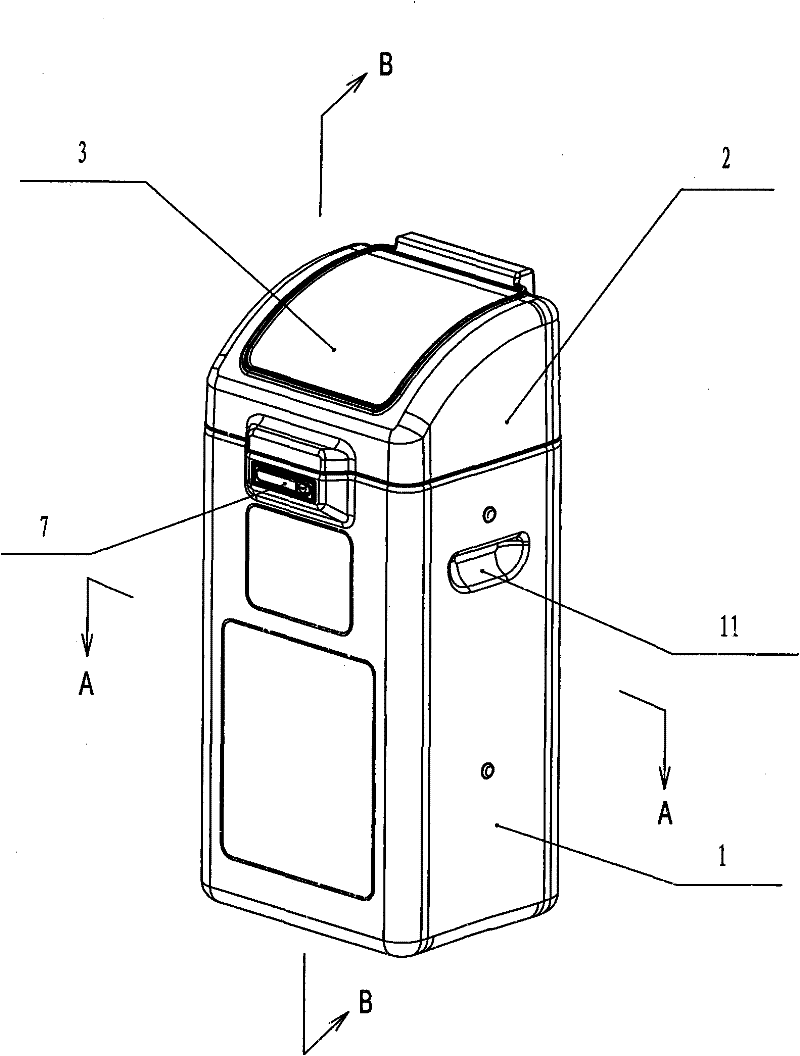

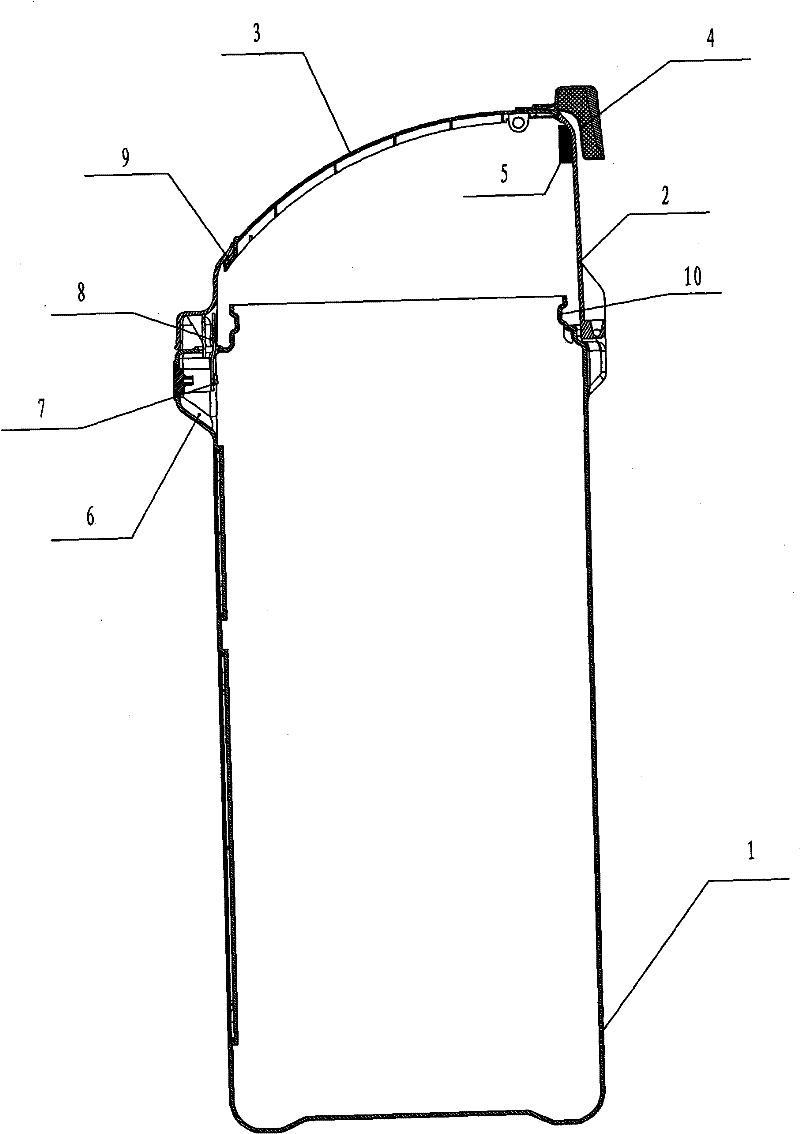

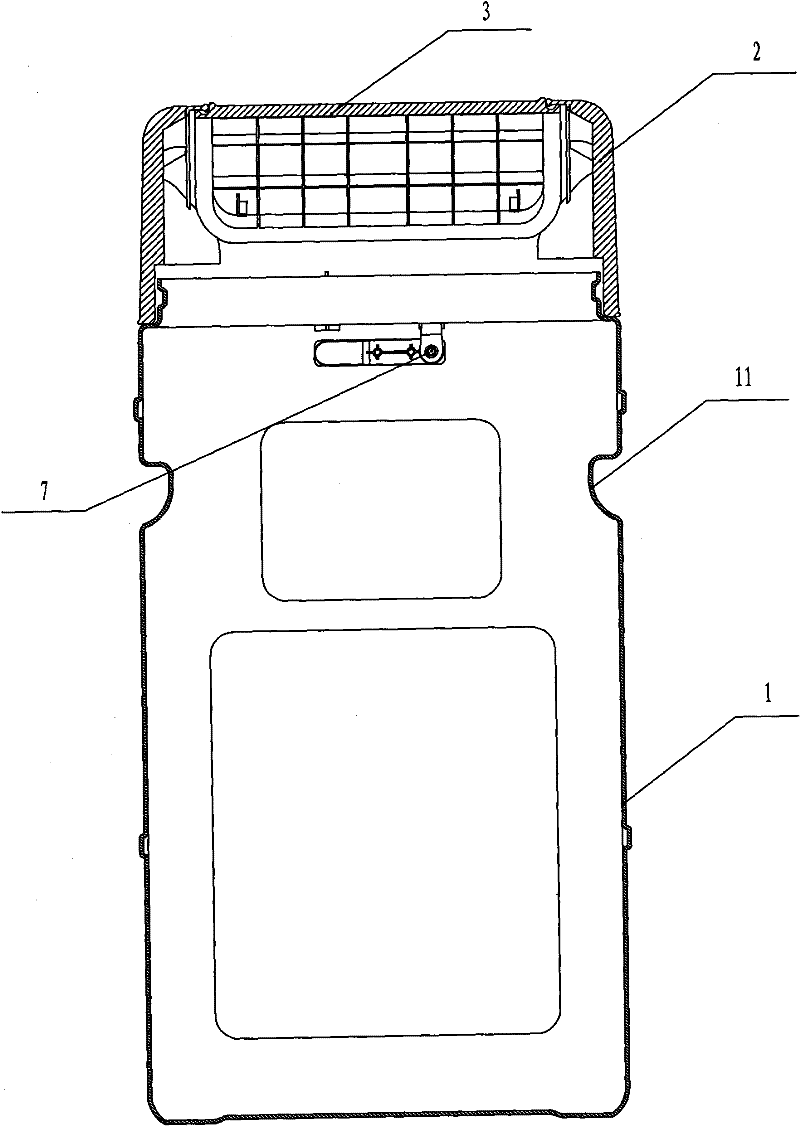

[0026] refer to figure 1 Shown, the waste sorting plastic collection box of the present embodiment comprises the lower barrel body 1 standing on the ground and the upper barrel body 2 hinged with the lower barrel body on one axis and unilaterally. The bucket cover 3 that fits in correspondingly to the feeding port and turns inwards; Figure 5 shown; as figure 2 As shown, the end of the lid is wrapped with an iron block 4 integrally injection-molded with the lid. The iron block is located behind the hinge point between the lid and the upper barrel body. The torque formed by the lid at the end of the iron block relative to the pivot point is greater than that of the lid The torque formed by the other end relative to the pivot point, while the weight of the iron block is greater than the weight of the bung from the pivot point to the front end of the bung; the inner wall of the upper barrel is also provided with a permanent magnet 5 corresponding to the iron block, and the perm...

Embodiment 2

[0031] This embodiment 2 is improved on the basis of embodiment 1. The difference between this embodiment 2 and embodiment 1 is that the plastic collection box of this embodiment 2 adopts a separate individual structure instead of connecting multiple collection boxes. together. Present embodiment 2 adopts the increased mechanism of independent individual structure mainly to be two major parts, i.e. drag hook and hanging box hook. The specific structure of the draw hook is: a draw hook that limits the opening angle of the upper barrel is also provided between the upper and lower barrels on the hinged side of the lower barrel and the upper barrel, and the two ends of the draw hook pass through the inner wall of the lower barrel respectively. Afterwards, it is connected with the upper barrel body. The hook is set to prevent the opening angle of the upper barrel body from being too large, and avoid the phenomenon that the upper barrel cover is turned over.

[0032]In order to fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com