Waste vulcanized butyl rubber desulfurization regeneration and preparation method and equipment thereof

A technology of regeneration equipment and vulcanization, which is applied in the chemical industry, can solve the problems of carbonization, complexity, and impact on product quality of rubber powder, and achieve the effect of overcoming carbonization, uniform desulfurization, and reasonable production process design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

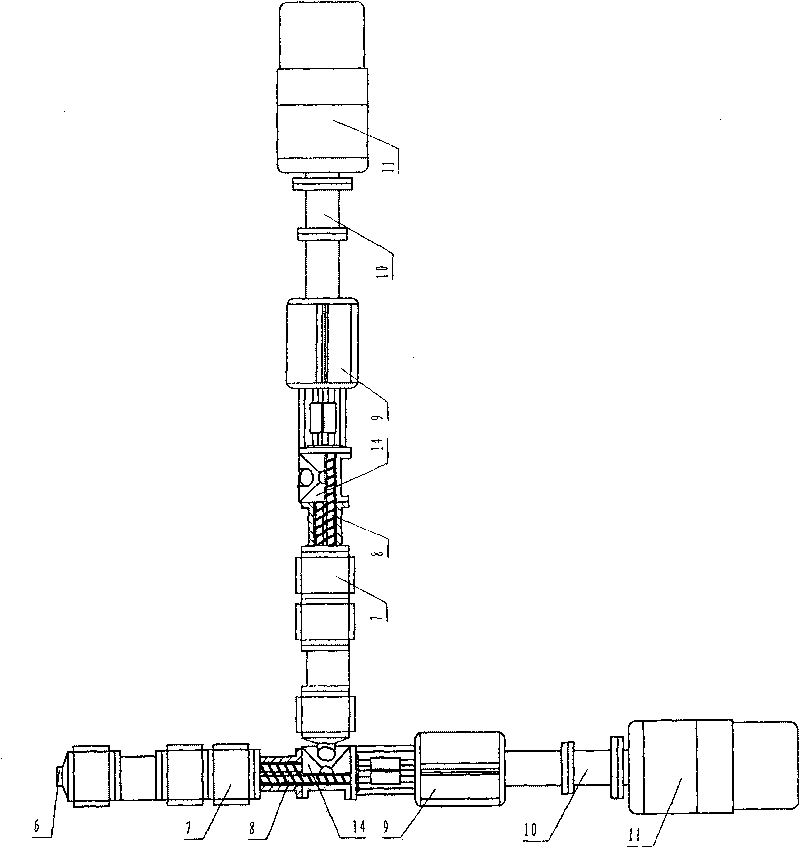

[0024] Choose two twin-screw extruders, the front twin-screw extruder is a twin-screw extruder with a screw diameter of 60mm, a screw length-to-diameter ratio of L / D=30, a compression ratio of 3, and a speed of 100 to 400 rpm. The rear twin-screw extruder is a twin-screw extruder with a screw diameter of 50 mm, a screw length-to-diameter ratio of L / D=30, a compression ratio of 3, and a rotation speed of 100 to 400 rpm. After the outlet head is connected to the feed port of the twin-screw extruder, the two twin-screw extruders are connected in series to form a twin-screw extrusion line (see attached figure 1 ).

[0025] The random sampling test indicators of waste vulcanized butyl rubber sheets or rings (car inner tubes of waste butyl rubber) to be recycled are: Mooney viscosity ML[(1+4)100°C] 67.25; tensile strength 10.01Mpa; Elongation 500.05%.

[0026] Preparation method: Put the waste vulcanized butyl rubber sheet into the front twin-screw extruder for forward and reverse...

Embodiment 2

[0028] The selected front screw extruder is a twin-screw extruder with a screw diameter of 60mm, a screw length-to-diameter ratio of L / D=30, a compression ratio of 3, and a rotation speed of 100-400 rpm. The rear screw extruder is a twin-screw extruder with a screw diameter of 50mm, the length-to-diameter ratio of the screw is L / D=30, the compression ratio is 3, and the speed is 100-400 rpm twin-screw extruder. The front twin-screw extruders are connected in series to form a twin-screw extruder.

[0029] The waste vulcanized butyl rubber (capsules of waste butyl rubber) to be regenerated is randomly sampled and tested as follows: Mooney viscosity ML[(1+4)100°C] 56.2; tensile strength 9.7Mpa; elongation at break 500.4% .

[0030] Preparation method: Add waste vulcanized butyl rubber into the front twin-screw extruder for forward and reverse multi-stage screw mixed extrusion. After the temperature of the material reaches 210° and the pressure is 3.0Mpa in the mechanism, the mate...

Embodiment 3

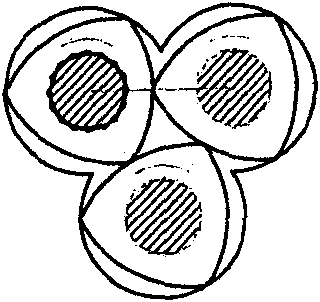

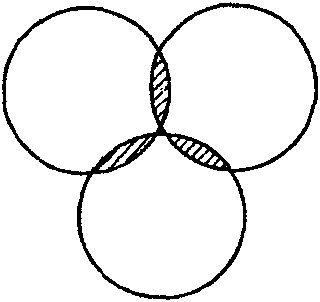

[0032] See attached figure 1, the preceding twin-screw extruder that the present invention selects is screw diameter 60mm, and screw rod length-diameter ratio L / D=30, and compression ratio is 3, and rotating speed is the twin-screw extruding mechanism of 100~400 revs / min, and the rear is three-screw extruder The variable-frequency speed-regulating three-screw extruder is meshed and connected in the shape of an inverted "pin", the diameter of the screw is 60mm, and the two extruders are connected in series to form a screw extrusion line.

[0033] The random sampling test indicators of waste vulcanized butyl rubber sheets (waste butyl rubber inner tubes) to be recycled are: Mooney viscosity ML[(1+4)100°C] 66.75; tensile strength 9.85Mpa; elongation at break 489.4% .

[0034] Preparation method: Put the waste vulcanized butyl rubber sheet into the front twin-screw extruder for forward and reverse multi-stage screw mixed extrusion. After the material temperature reaches 200° and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com