Weft insertion method and weft insertion device of rapier loom

A technology of rapier looms and weft insertion devices, which is applied to looms, textiles, textiles, and papermaking, and can solve problems such as looping, fabric quality degradation, and inability to insert wefts next time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

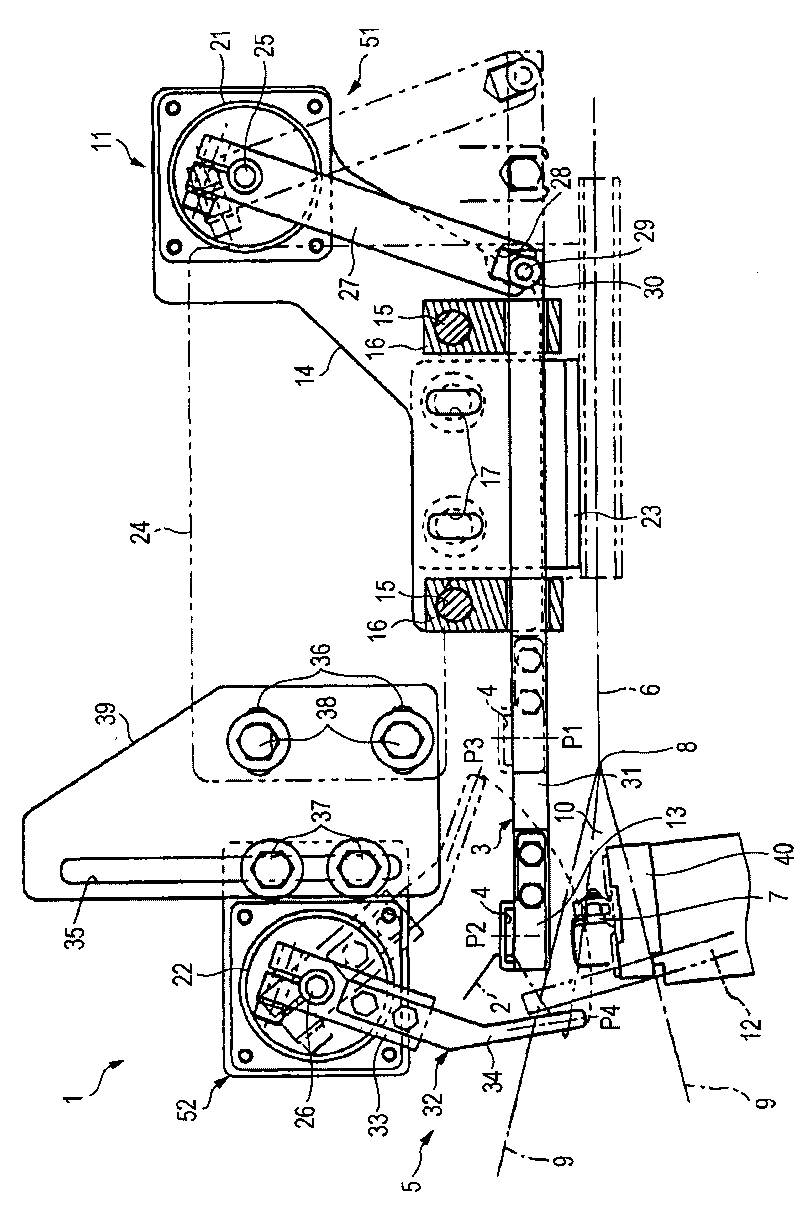

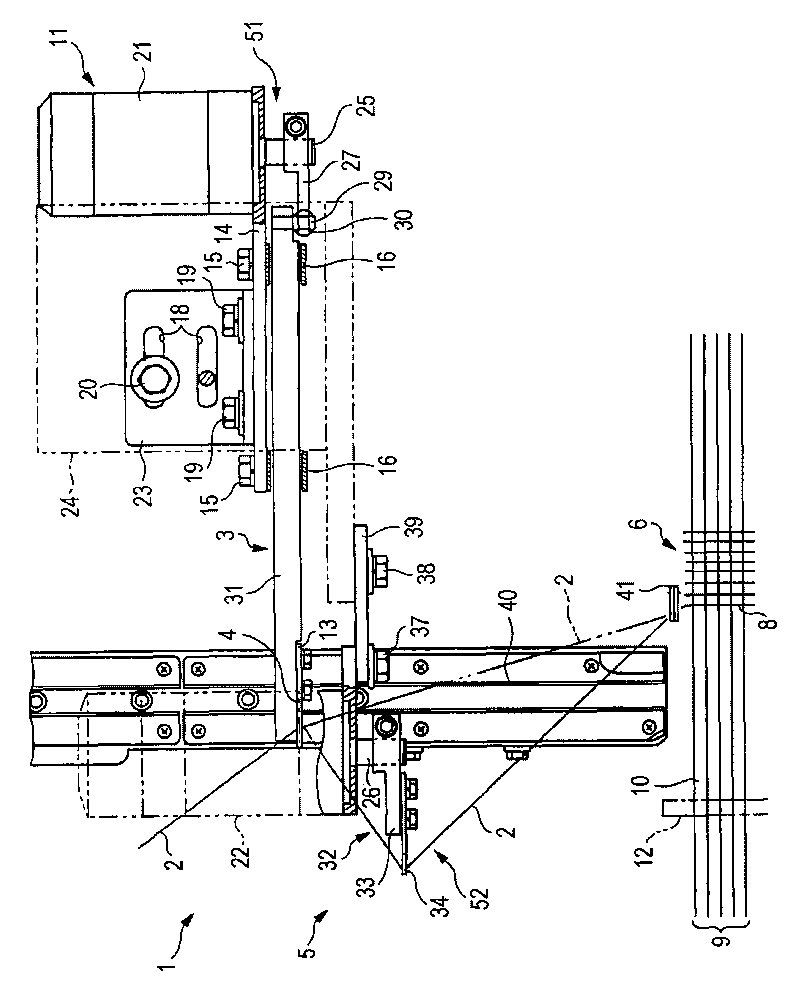

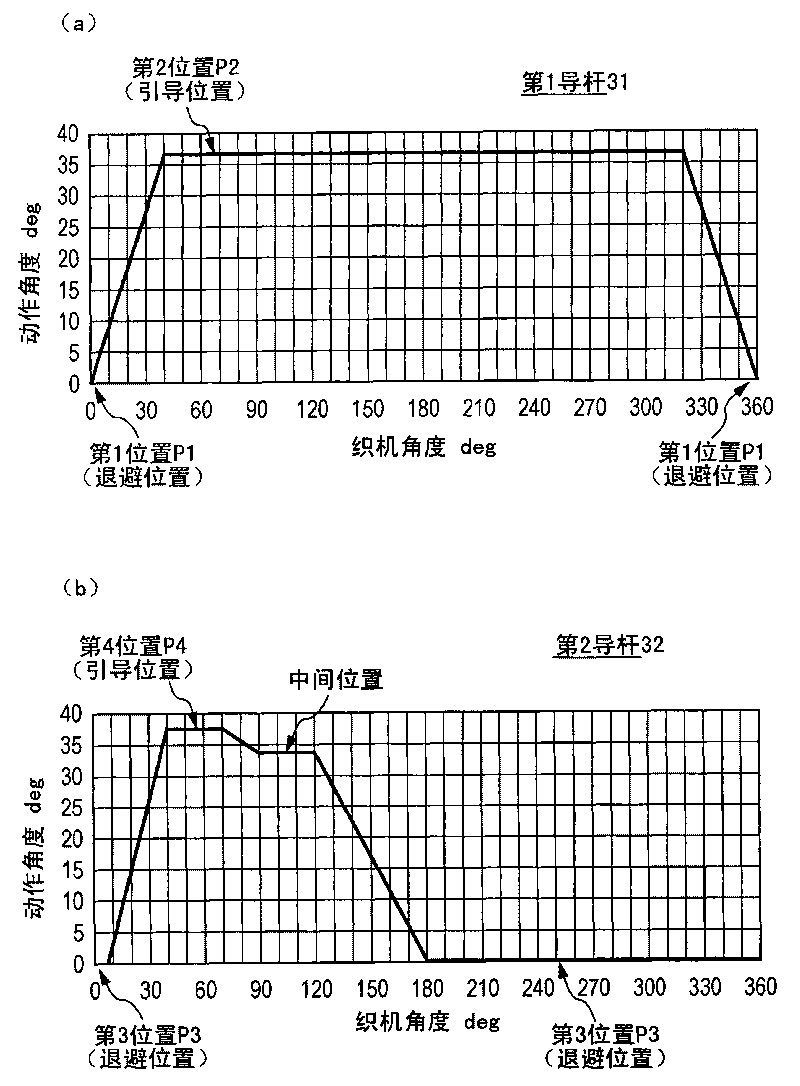

[0039] Figure 1 to Figure 4 An example of the weft insertion device 1 of the rapier loom according to the present invention is shown. In the rapier loom here, as an example, the rapier head 7 for insertion is inserted into the opening 10 of the warp yarn 9 from the yarn supply side, and the rapier head 71 for weft loading is inserted into the opening 10 of the warp yarn 9 from the opposite side of the yarn supply, A double-sided rapier loom in which the weft yarn 2 is delivered from the rapier head 7 to the rapier head 71 at an intermediate point in the opening 10 for weft insertion. Moreover, the weft insertion device 1 of the illustrated rapier loom is an example of one-color weft insertion of the weft yarn 2 supplied from a single yarn supply body by the rapier head 7 and the rapier head 71, and the weft yarn 2 is used as an example. flat yarn.

[0040] exist figure 1 and figure 2 Among them, the weft insertion device 1 includes a weft yarn guide mechanism 5 that guid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap