Installation structure of sandwich color steel composite plate drop ceiling

A technology for installing structures and composite boards, which is applied to ceilings, building components, building structures, etc., and can solve problems such as high cost, large amount of glue used, and poor sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

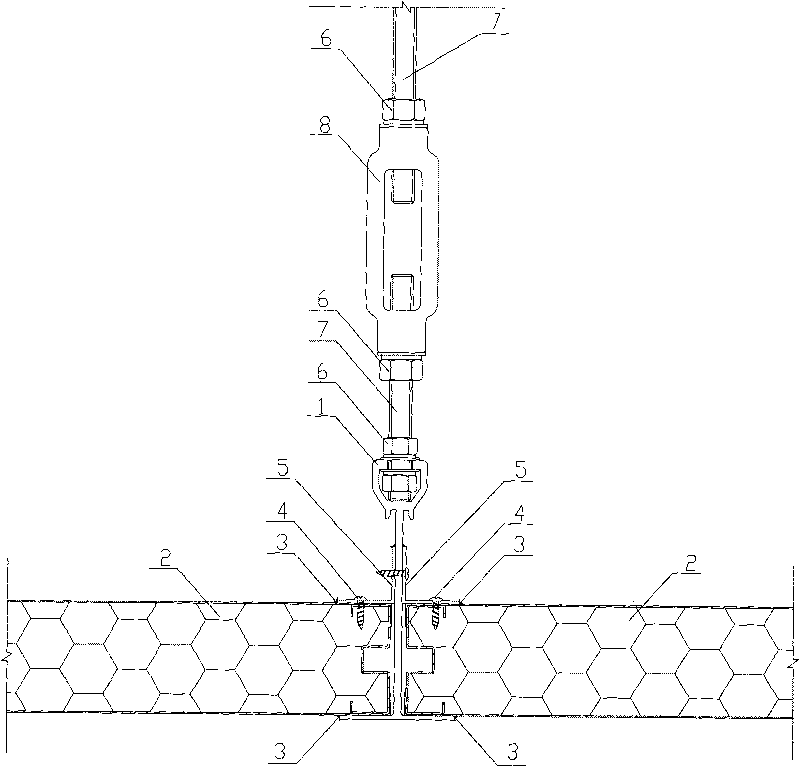

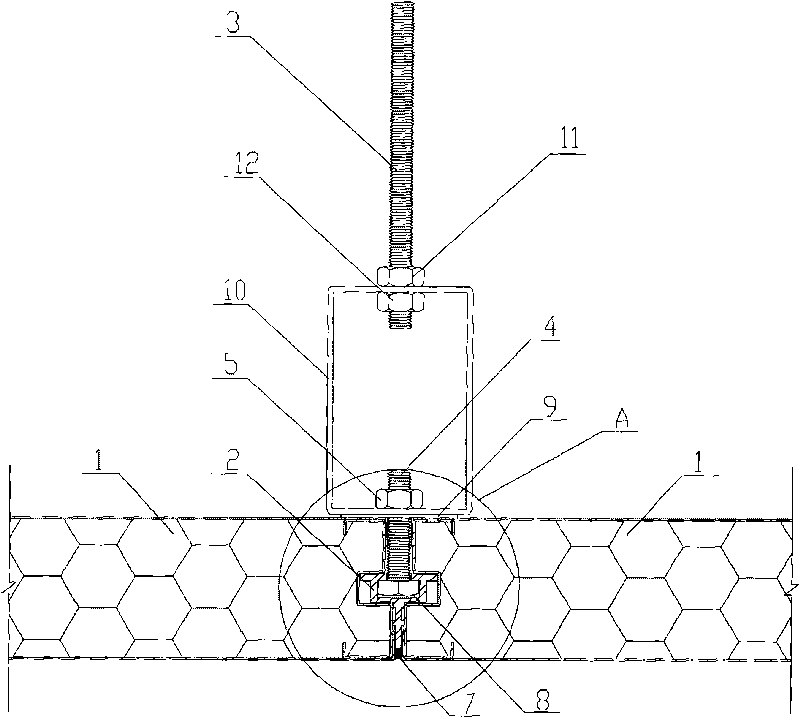

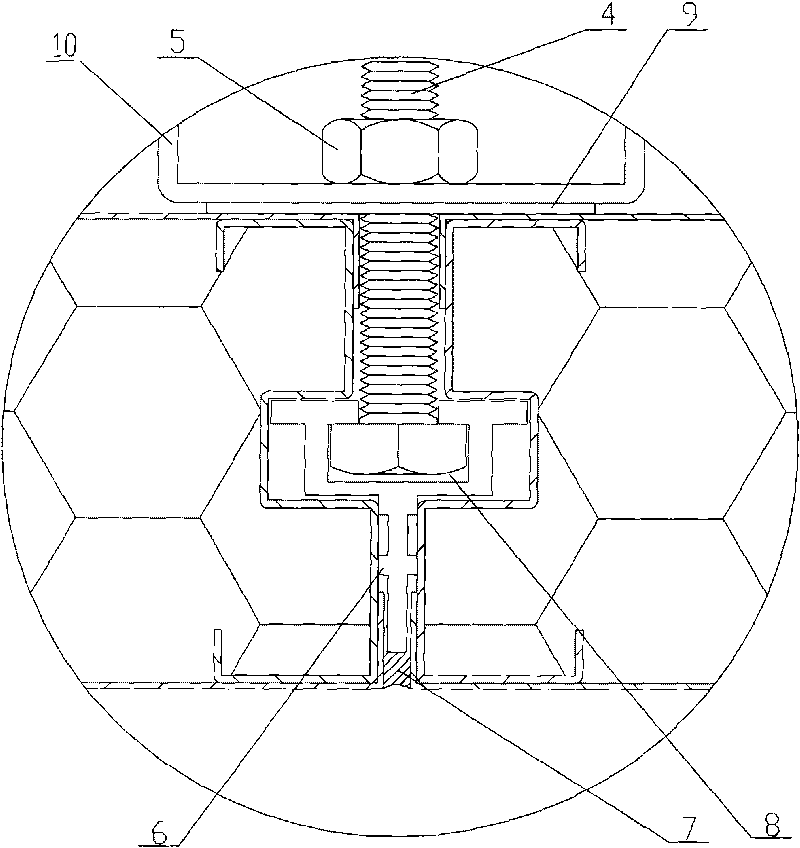

[0012] See figure 2 , image 3 , which includes a sandwich color steel composite panel 1, a hanging beam 2, a connecting piece, and a through-wire suspender 3. The hanging beam 2 is located inside the gap between two sandwich color steel composite panels 1, and the hanging beam 2 is not exposed to the sandwich core. On the upper surface and the lower surface of the color steel composite panel 1, the lifting point of the hanging beam 2 is located at the largest space in the gap between the two sandwich color steel composite panels 1, and the lifting point is connected to the upper part through the T-bolt 4 and the nut 5 The connecting piece is press-fitted on the upper surface of the sandwich color steel composite panel 1, the connecting piece is connected with the wire suspender 3, the lower end of the hanging beam 2 has a gap control divider 6, and the combination of two sandwich color steel composite panels 1 The gaps on the lower surface are sealed and connected by a seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com