Process for manufacturing shampoo bed

A manufacturing process and technology of hair washing bed, which can be applied to hair or scalp washing device, clothing, application, etc. It can solve the problems that affect the cleanliness and sanitation of the bed board, shorten the service life of the bed board, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

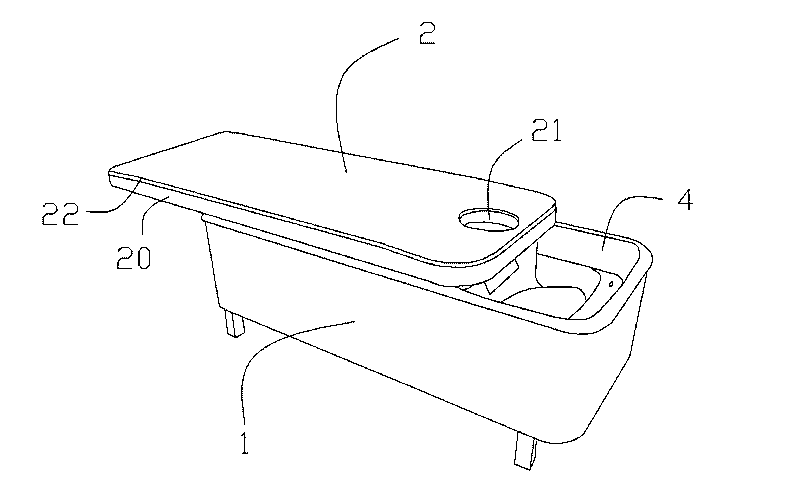

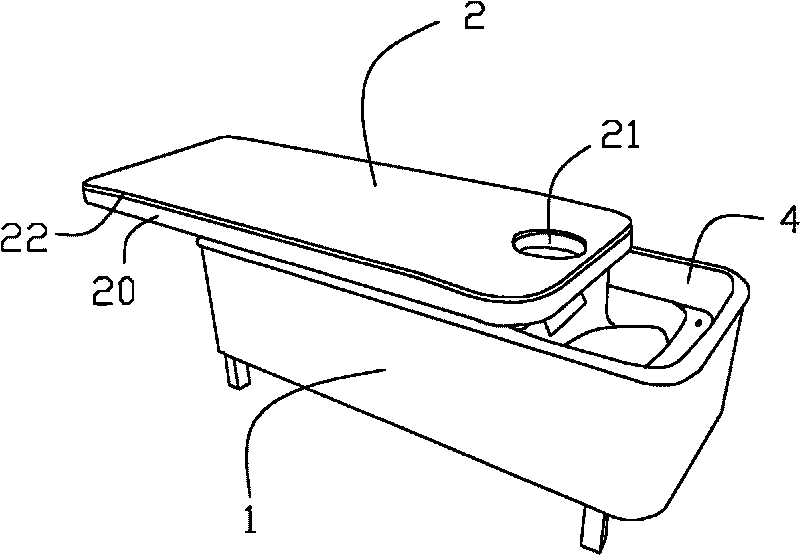

[0013] See figure 1 As shown, the manufacturing process of a shampoo bed of the present invention includes a bed body 1, a bed board 2 for lying on a person, and a shampoo basin 4, which is located in the bed body 1, and the bed board 2 is arranged above the shampoo basin 4, the bed board 2 is also provided with a water outlet 21 for sewage to flow out; the bed board 2 has a structure including a wooden board (not shown) and a sponge body arranged on the wooden board (Not shown), and the leather 20 used to cover the sponge body. The leather 20 is pressed and integrally formed by a mold, so that sewage does not flow into the sponge body, but flows away directly along the leather. , Or run along the water outlet; it is clean, hygienic, and has a long service life. Wherein, the leather bending part is a smooth arc surface 22, which is convenient for the sewage to flow away. The bed board is provided with a handle for pulling and pushing the bed board.

[0014] The manufacturing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com