Steering handle device of motor cycle

A motorcycle and handle technology, which is applied in the field of motorcycle steering handle devices, can solve the problems that are unfavorable to the overall durability and safety of the motorcycle, the instrument panel 13 cannot operate normally, and the bends are prone to breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the drawings.

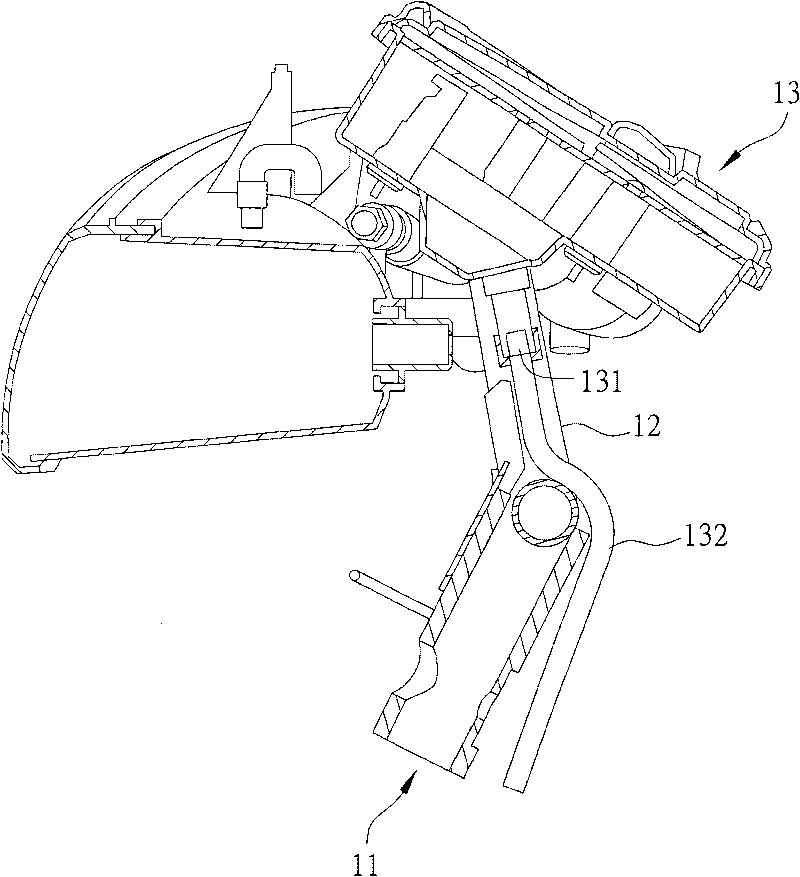

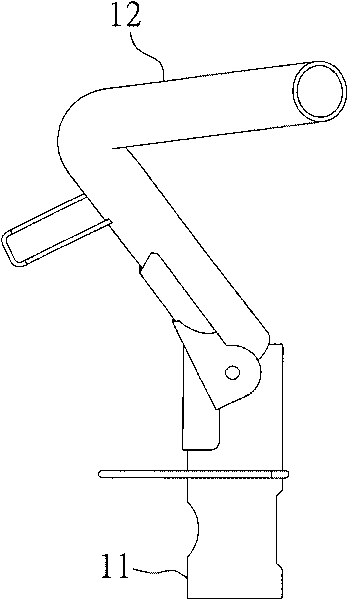

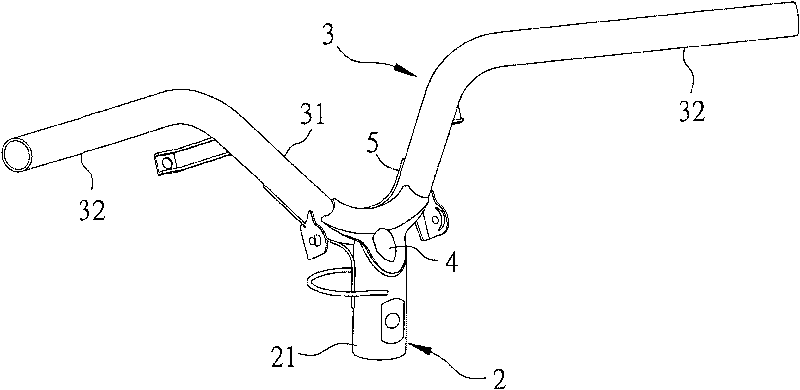

[0026] refer to image 3 , 4 , and refer to Figure 5 A preferred embodiment of the motorcycle steering handle device of the present invention is to have a body 103, a display panel 104 arranged on the body 103, and a display panel 104 spaced apart from the body 103. The steering joint 101 is used in conjunction with the instrument panel 100 of a wire 102 extending from the steering joint 101. The steering handle device of the motorcycle includes: a connecting pipe 2, a handle pipe 3, a first reinforcing piece 4, and A second reinforcing sheet 5 .

[0027] Before the present invention is described in detail, it should be noted that the steering joint 101 is defined with an extension axis 105 axially extending from the steering joint 101 , and an extens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com