Method for optimizing DMD exposure through dislocation superposition

An image and sub-frame technology, which is applied in the field of dislocation superimposition to optimize DMD exposure, can solve problems such as image edge jaggedness, and achieve the effect of improving graphic breakage and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

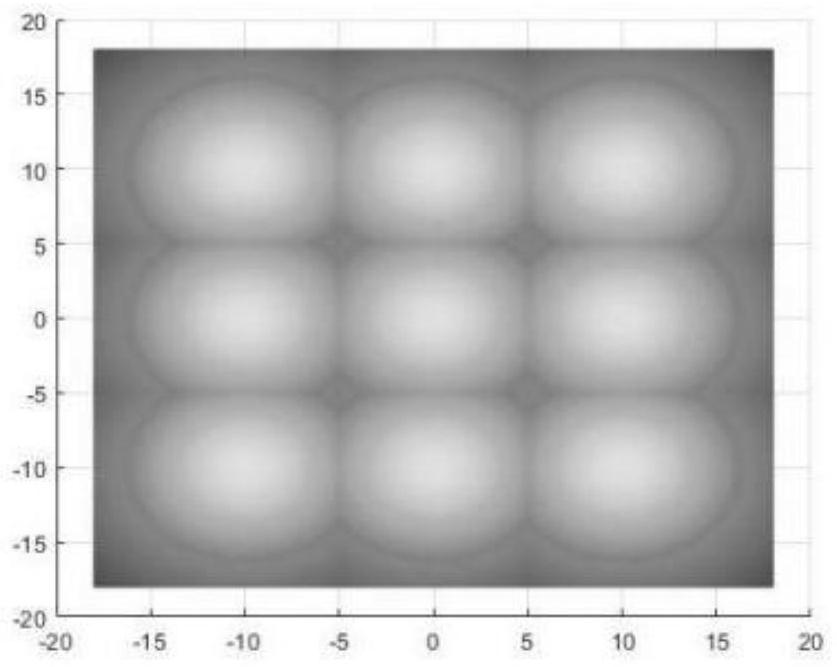

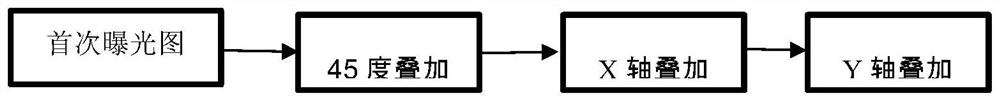

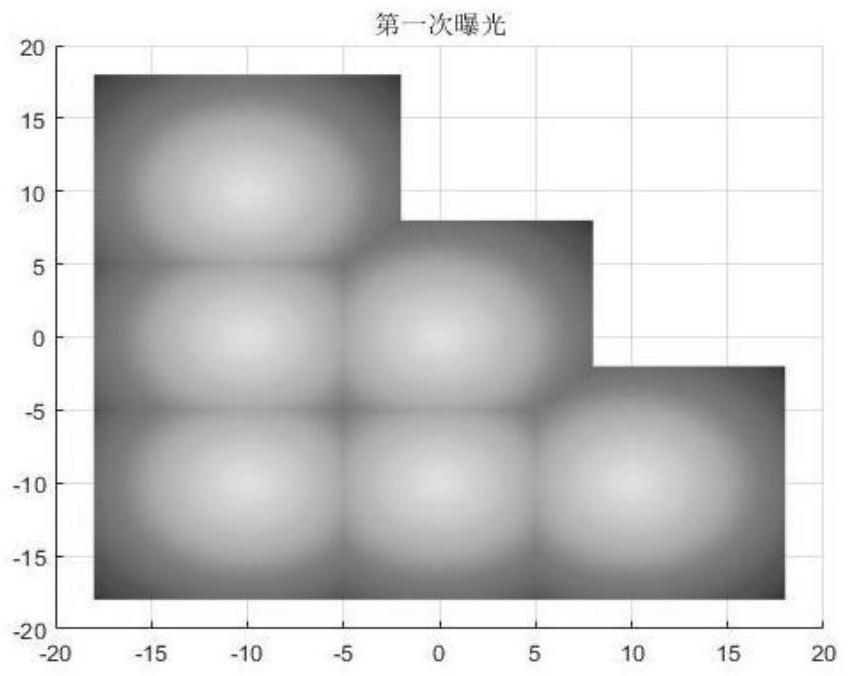

[0019] combine Figure 1 to Figure 6 Describe this implementation mode, a method for optimizing DMD exposure by dislocation stacking, such as figure 1 It is a mathematical model of DMD micromirror energy distribution.

[0020] The main reason for improving the problem of pattern breakage is the structure of the DMD itself. At present, the size of the usual DMD pixel unit is 13.68 μm, the effective pixel size is 12.68 μm, and there is a 1 μm interval between adjacent pixels. Therefore, under ideal conditions, the energy on each micromirror has a Gaussian distribution, and there are large defects in the center of the rectangle formed by every four adjacent pixels between every two pixels, causing pattern breaks.

[0021] The energy distribution of each micromirror of an ideal DMD is not uniform, figure 1 It is the energy distribution diagram of the DMD micromirror. The energy on each micromirror is Gaussian distributed, and the exposure energy is attenuated around the center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com