Polyamide composition capable of being stably molded and processed

A polyamide composition and molding processing technology, applied in the field of engineering plastics, can solve problems such as difficulty in controlling the degree of reaction, gelation, and aggravated melt fracture

Pending Publication Date: 2020-11-17

JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] For branching agents or crosslinking agents with high reactivity, the processing difficulty is that it is difficult to control the degree of reaction in the melt extrusion process, especially when the branching agent or crosslinking agent cannot be mixed uniformly, local Vigorous reaction at high concentrations can form a gel-like product

However, industrial production conditions have very limited dispersibility for powdery or granular branching agents or crosslinking agents.

[0011] When the above-mentioned disclosed technology uses polytetrafluoroethylene, the melt is prone to fracture during processing

Problems caused by melt fracture include inability to pull pellets smoothly when blending with resins for melt extrusion, extrusion of melt pipes during blow molding, or cracking during blowing

However, the use of anhydride polymers or ionizing polymers may lead to gelation (due to localized violent reactions of highly reactive high-concentration anhydride polymers) or exacerbate melt fracture

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

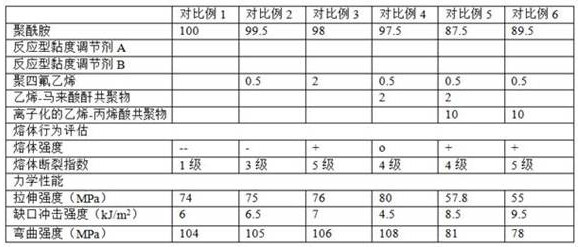

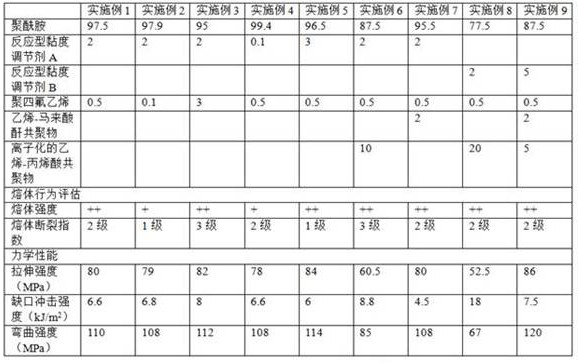

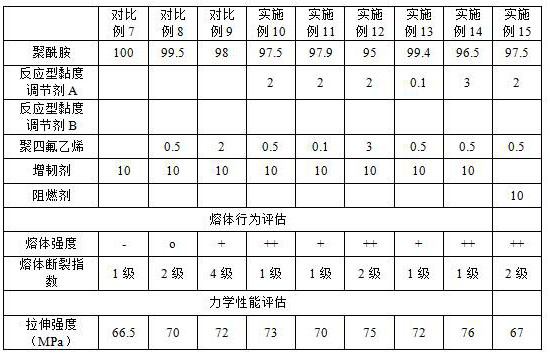

[0058] Table 1 Raw materials in Examples and Comparative Examples

[0059]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt tension | aaaaa | aaaaa |

| Melt tension | aaaaa | aaaaa |

| Melt tension | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a polyamide composition capable of being stably molded and processed. The polyamide composition comprises polyamide, a reactive viscosity regulator, fibrous polytetrafluoroethylene and an impact modifier. The polyamide composition provided by the invention has excellent melt strength and melt fracture resistance, has excellent processability, is especially suitable for extrusion blow molding, 3D blow molding or other blow molding, has balanced mechanical properties, and is suitable for producing any type of molded products, especially molded products with hollow structures.

Description

Technical field [0001] The invention belongs to the field of engineering plastics, and particularly relates to a polyamide composition that can be stably formed and processed. Background technique [0002] Polyamide is an engineering plastic with excellent high heat resistance, but it is not suitable for extrusion blow molding due to lack of sufficient melt strength. Extrusion blow molding has been widely used in the industrial production of hollow products. In order to use polyamide materials to meet the requirements of extrusion blow molding to produce hollow products with high heat resistance, it is necessary to adjust the melt viscosity of the polyamide materials and improve the melt strength. [0003] Patent US4804703 discloses the use of fiberizable polytetrafluoroethylene, ionized ethylene-α or β ethylenically unsaturated carboxylic acid polymers to make mineral-filled polyamides satisfy blow molding. [0004] Patent US5408000A discloses a flexible thermoplastic blow moldable...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L77/02C08L27/18C08L23/08C08K5/14C08K5/18

CPCC08L77/02C08L2205/03

Inventor 林洁龙杨波张超徐洪耀丁正亚肖军华王飞刘纪庆叶士兵安朋邱志强

Owner JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com