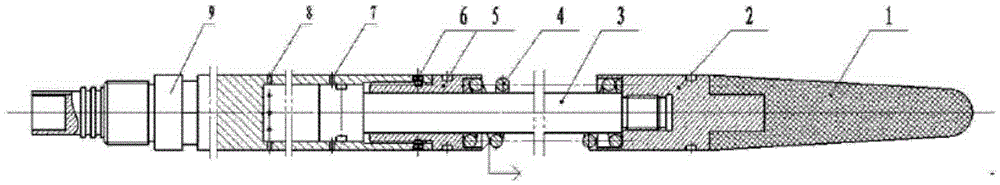

Guide buffer device for drill-pipe conveyed logging instrument

A buffer device and guide device technology, applied in construction and other directions, can solve problems such as buffer rubber cone breakage and instrument damage, and achieve the effects of improving fracture, prolonging the action time, and protecting from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

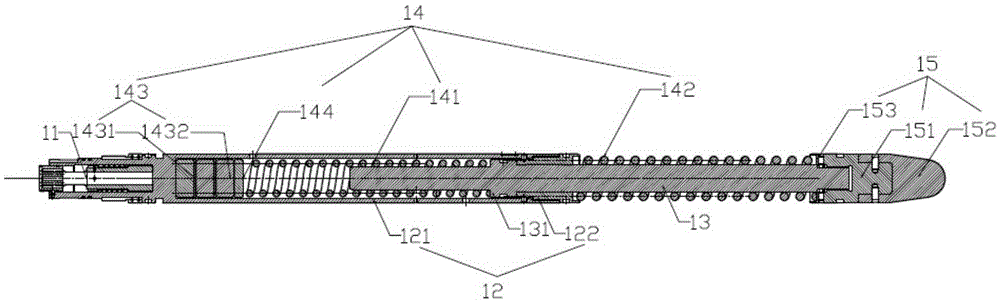

Embodiment 1

[0016] Embodiment one, such as figure 2 As shown, the present invention provides: a guiding and buffering device for a drill pipe conveying type logging instrument, including a connecting body 11, a fixing device 12, a core rod 13, a buffering device 14 and a guiding device 15, and the fixing device 12 includes a housing 121 and an installation The fixing ring 122 at one end of the housing 121, the connecting body 11 is installed on the other end of the housing 121, the rear end of the core rod 13 is placed in the cavity of the housing 121 through the fixing ring 122, and there is a convex part 131 in the middle of the core rod 13 to prevent the core After the rod 13 is installed, it is separated from the fixed ring 122. The guide device 15 is installed on the front end of the core rod 13 through the fastening screw 153. The buffer device 14 is installed on the outside of the core rod 13 and in the cavity of the shell 121. The buffer device 14 includes a The rear end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com