Bituminous mixture proportion design method based on tightest state

A mix ratio design, asphalt mixture technology, applied in the field of asphalt mixture ratio design, to achieve the effect of saving asphalt resources, simple design parameters, reasonable asphalt ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific examples, and the following examples are only used to illustrate the present invention rather than limit the present invention.

[0034] According to the method for designing the proportion of asphalt mixture based on the most compact state of the present invention, its design process specification is as follows:

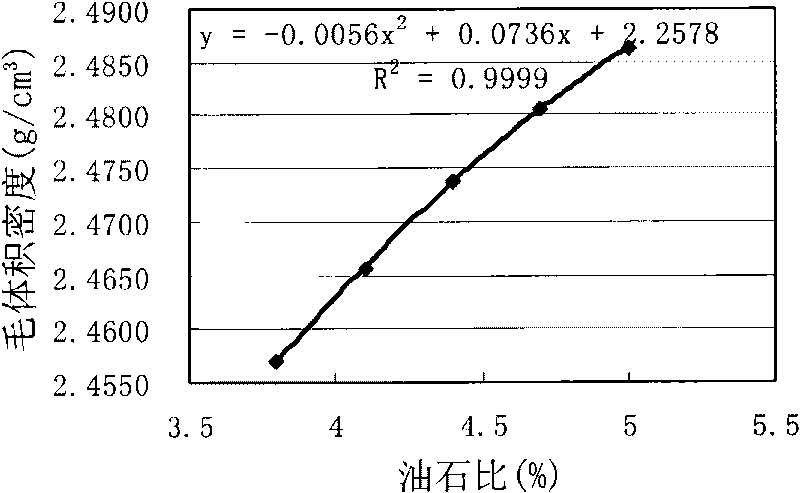

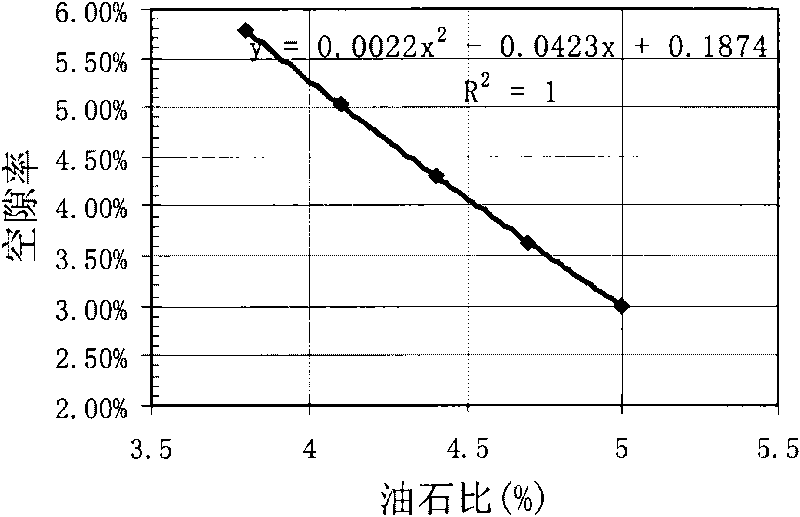

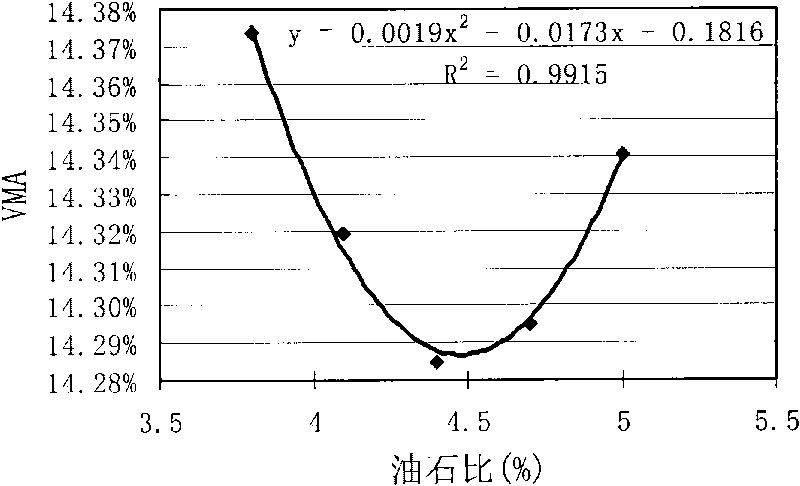

[0035] 1. Determine the range of the best asphalt-stone ratio covering the gradation based on experience, generally set 5-6 asphalt-stone ratios at intervals of 0.3-0.4% for testing, and the sample size of parallel test pieces under each asphalt-stone ratio is generally not less than 4 indivual.

[0036] 2. Weigh the required stones according to the proportion of stones, and make preparations before forming the test pieces according to the current standard "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering". Molding is carried out according to the select...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com