Blade modeling method for hydraulic torque converter

A technology of hydraulic torque converter and blade, applied in the field of hydraulic torque converter, can solve the problems of non-closed two-dimensional-three-dimensional curve, analytical description of the blade, inability to thicken, etc., to achieve strong adaptability, good flexibility, The effect of concise design parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

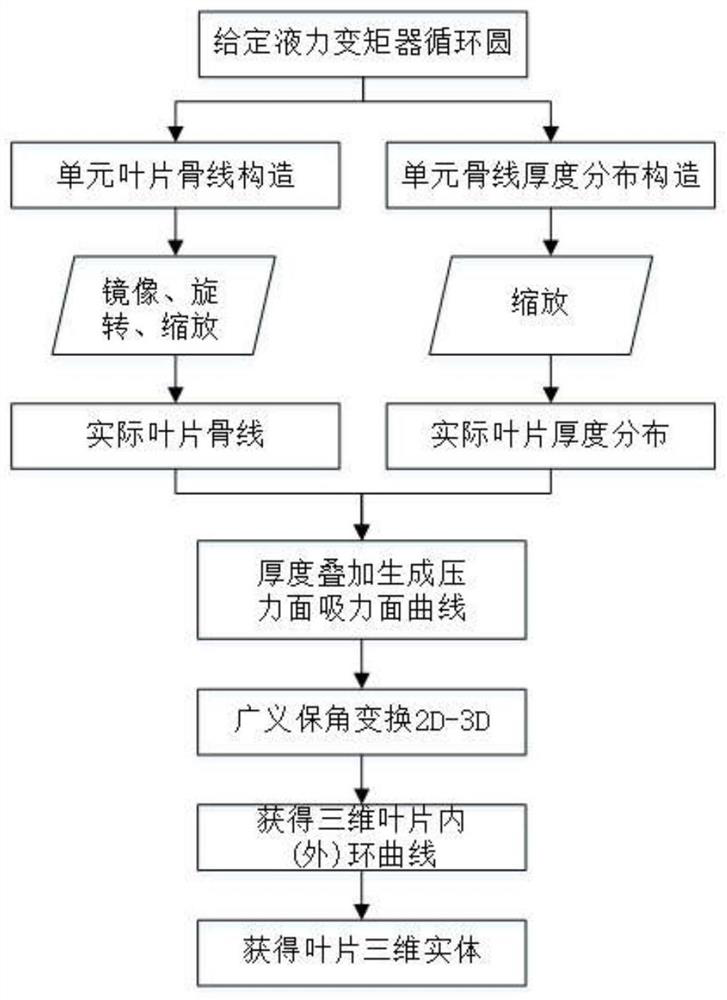

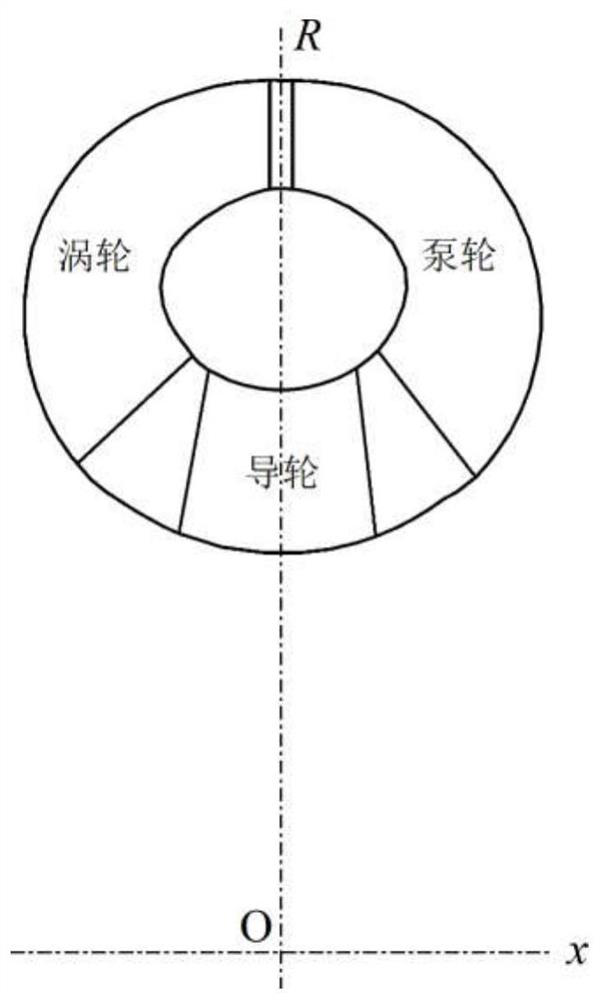

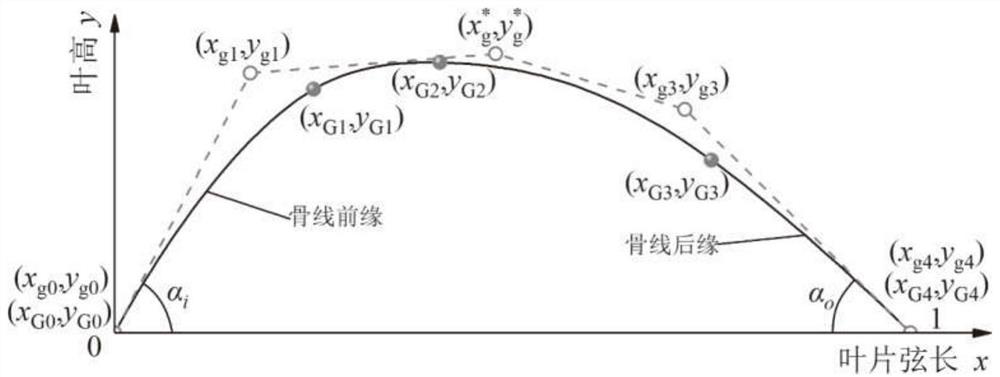

[0065] The invention provides a construction method of a two-dimensional blade profile of a hydraulic torque converter based on non-uniform rational B-splines. The core content of the invention is: using cubic non-uniform rational B-spline open curves and cubic non-uniform The B-spline closed curve constructs the unit blade bone line and the unit blade thickness distribution curve respectively, and then mirrors, rotates, and scales the unit blade bone line and the unit blade thickness distribution control point matrix to obtain the actual blade bone line and actual blade thickness distribution curve. The actual blade thickness is superimposed on the actual blade bone normal to obtain the two-dimensional profile of the pressure surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com