Fuel pump

A fuel pump and fuel technology, applied in the direction of pumps, liquid fuel feeders, liquid fuel engines, etc., can solve the problems of reduced pump efficiency, fuel leakage, etc., and achieve the effects of inhibiting contact, inhibiting wear, and high pump efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0020] Embodiment 1 according to the present invention will be described based on the drawings.

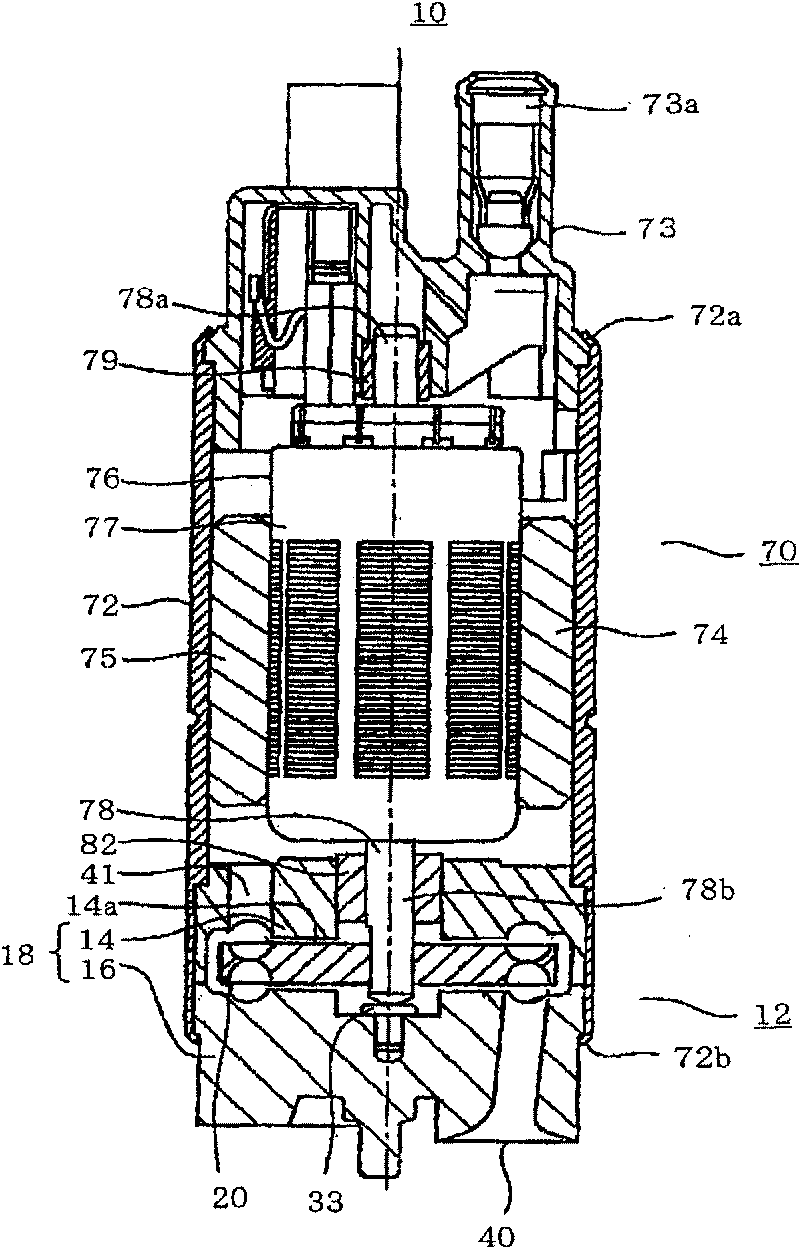

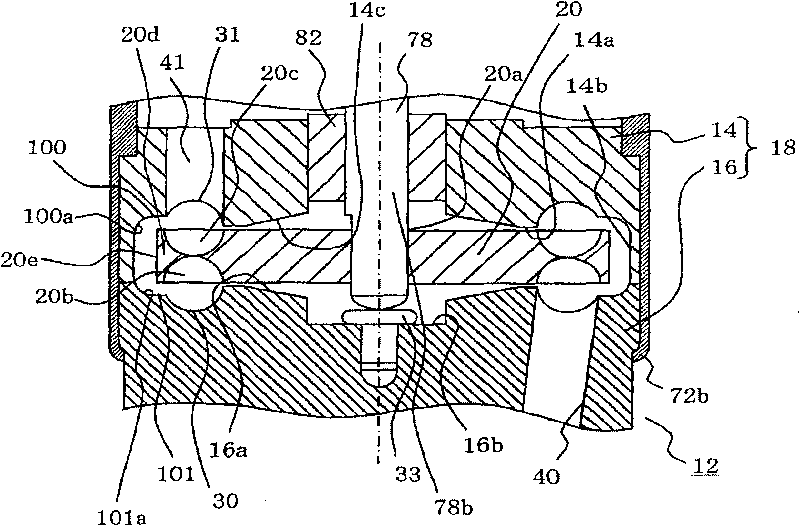

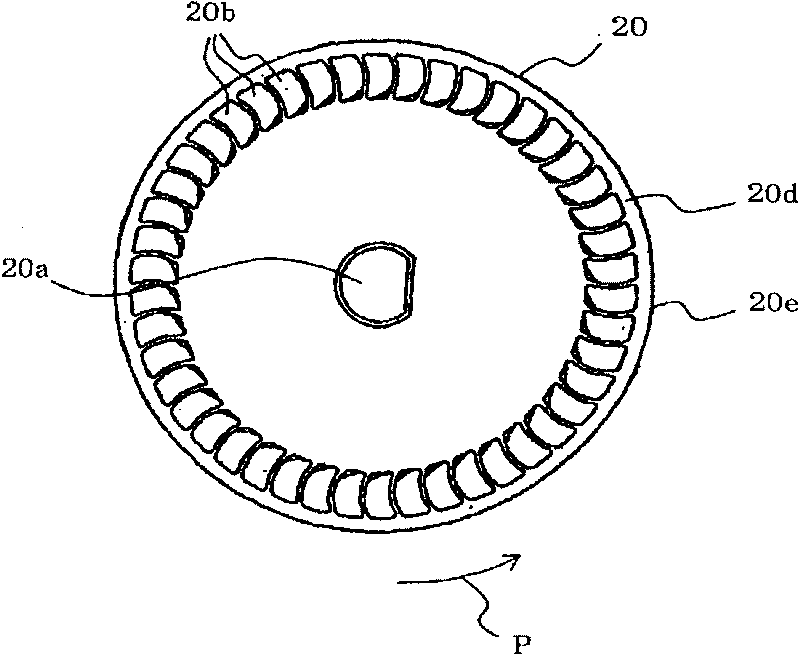

[0021] First, refer to figure 1 , illustrating the mechanical structure of the fuel pump. like figure 1 As shown, the fuel pump 10 is composed of a motor portion 70 and a pump portion 12 .

[0022] The motor unit 70 has a housing 72 , a motor cover 73 , magnets 74 and 75 , and a rotor 76 . The casing 72 is formed in a substantially cylindrical shape. The motor cover 73 passes the upper end 72a of the housing 72 (the figure 1 The top and bottom of the fuel pump 10 are crimped inwardly to be fixed on the casing 72 . A discharge port 73 a opening upward is formed in the motor cover 73 . Magnets 74 , 75 are fixed on the inner wall of housing 72 . The rotor 76 has a main body 77 (composed of laminated iron cores, coils, etc.) and a shaft 78 penetrating the main body 77 up and down. The upper end portion 78 a of the shaft 78 is rotatably mounted on the motor cover 73 via a beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com