Glass evacuated collector tube with built-in compounded metal profile tube

A technology of vacuum heat collecting tubes and metal profiles, which is applied to solar collectors using working fluids, solar collectors, heating devices, etc., can solve the problems of large thermal resistance, long heat transfer path, and low heat transfer efficiency. Achieve the effects of simple connection, stable and durable quality, and wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

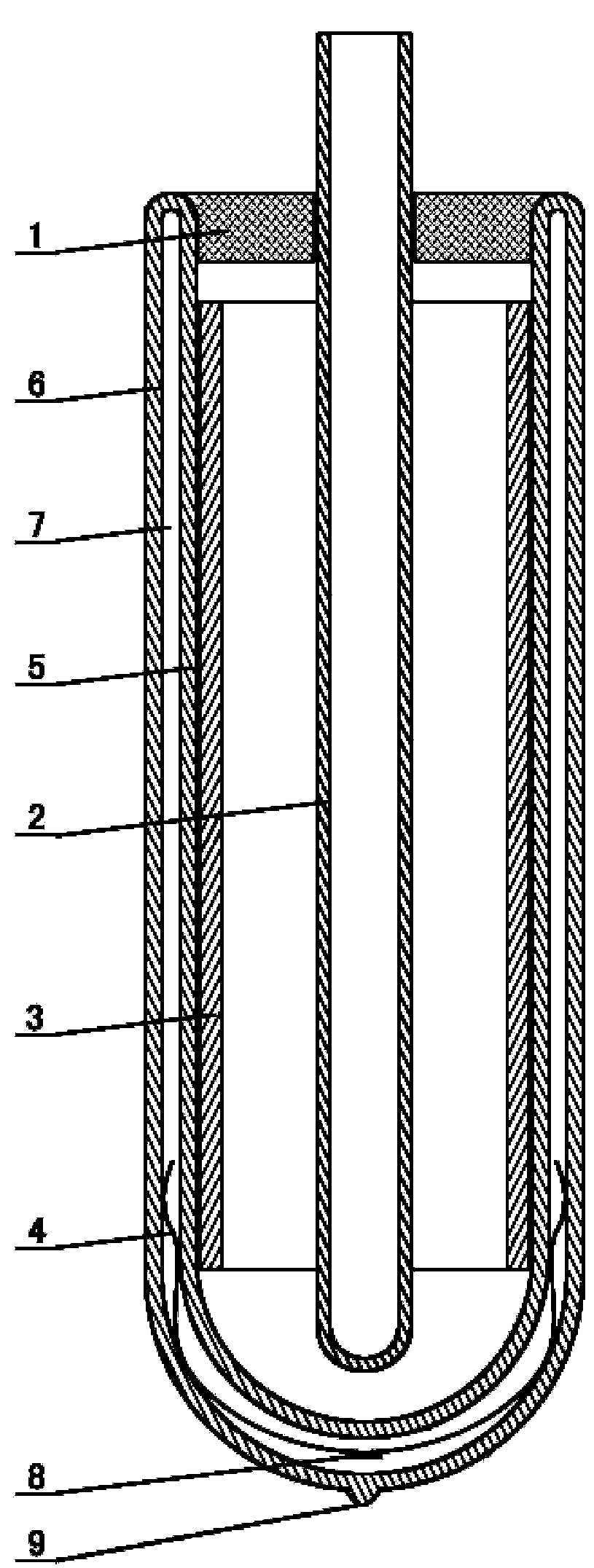

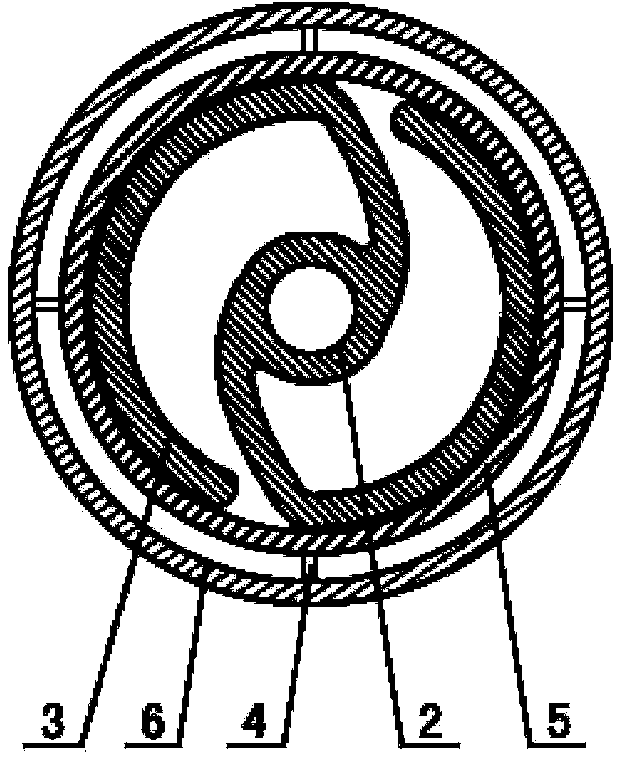

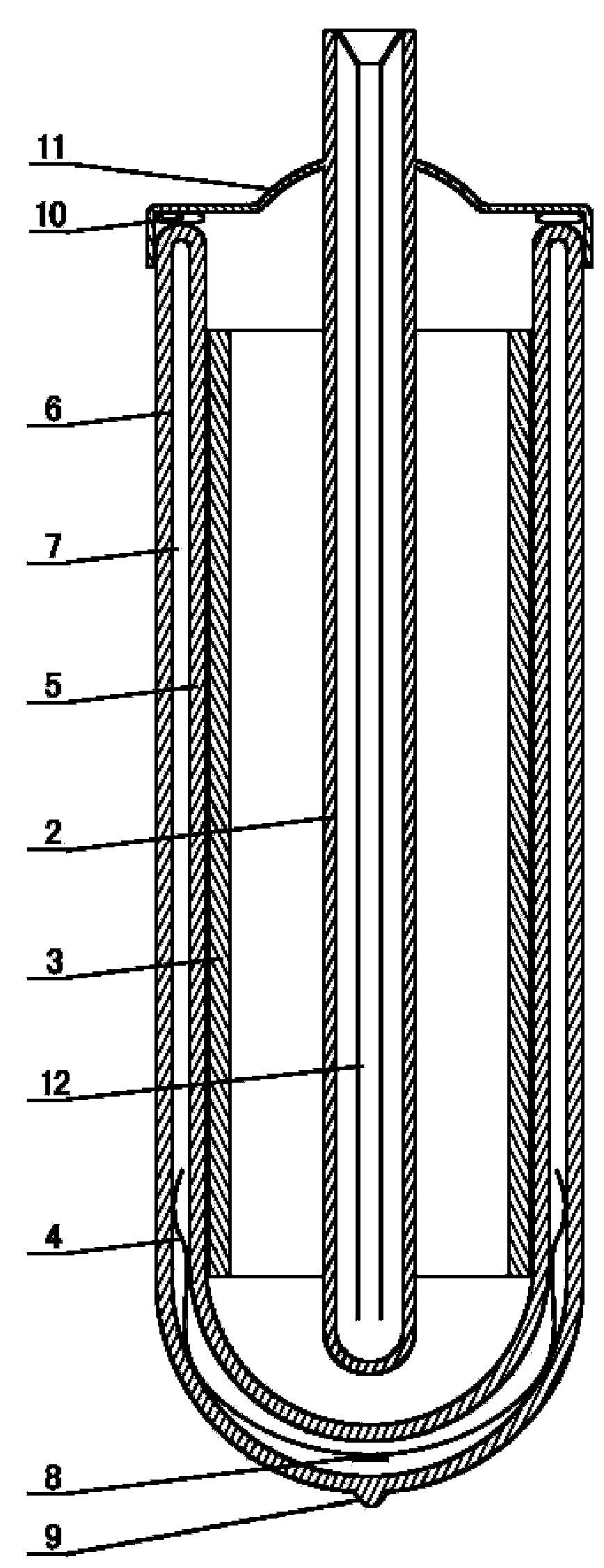

[0025] Such as figure 1 , figure 2 As shown: the glass vacuum heat collecting tube with metal profile tube installed inside the tube, the metal profile tube is a metal tube 2 with metal fins, one end is closed and the other end is open, and the metal tube 2 has two metal rib fins 3 . The glass vacuum heat collecting tube of the present invention comprises: an outer glass cover tube 6, an inner glass tube 5, a support bullet 4, a getter 8, and an exhaust nozzle 9, and one end of the opening of the inner glass tube 5 is connected with the outer glass cover tube 6, closed The other end is supported in the outer glass cover tube 6 by the support clip 4 with getter 8, and the exhaust nozzle 9 is sealed after vacuumizing the interlayer of the inner glass tube 5 and the outer glass cover tube 6 through the exhaust nozzle 9, A vacuum chamber 7 is formed. The metal profile tube is inserted in the nozzle of the glass vacuum heat collecting tube through the sealing plug 1 .

[0026] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com