Test bench for tightness of oil conduit of engine camshaft

A technology for testing benches and camshafts, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at leakage points, etc. It can solve the problems of preventive measures, lack of detection tools and methods, etc., and achieve Easy to operate, ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

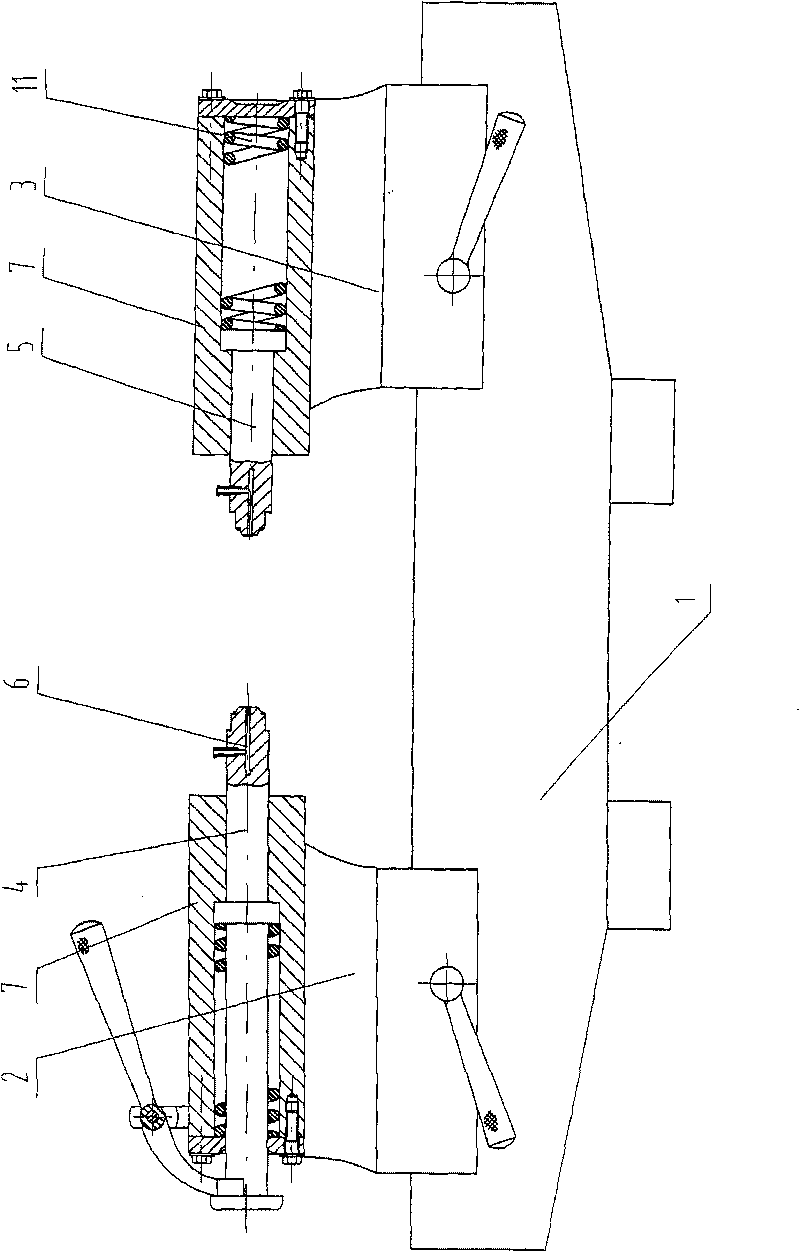

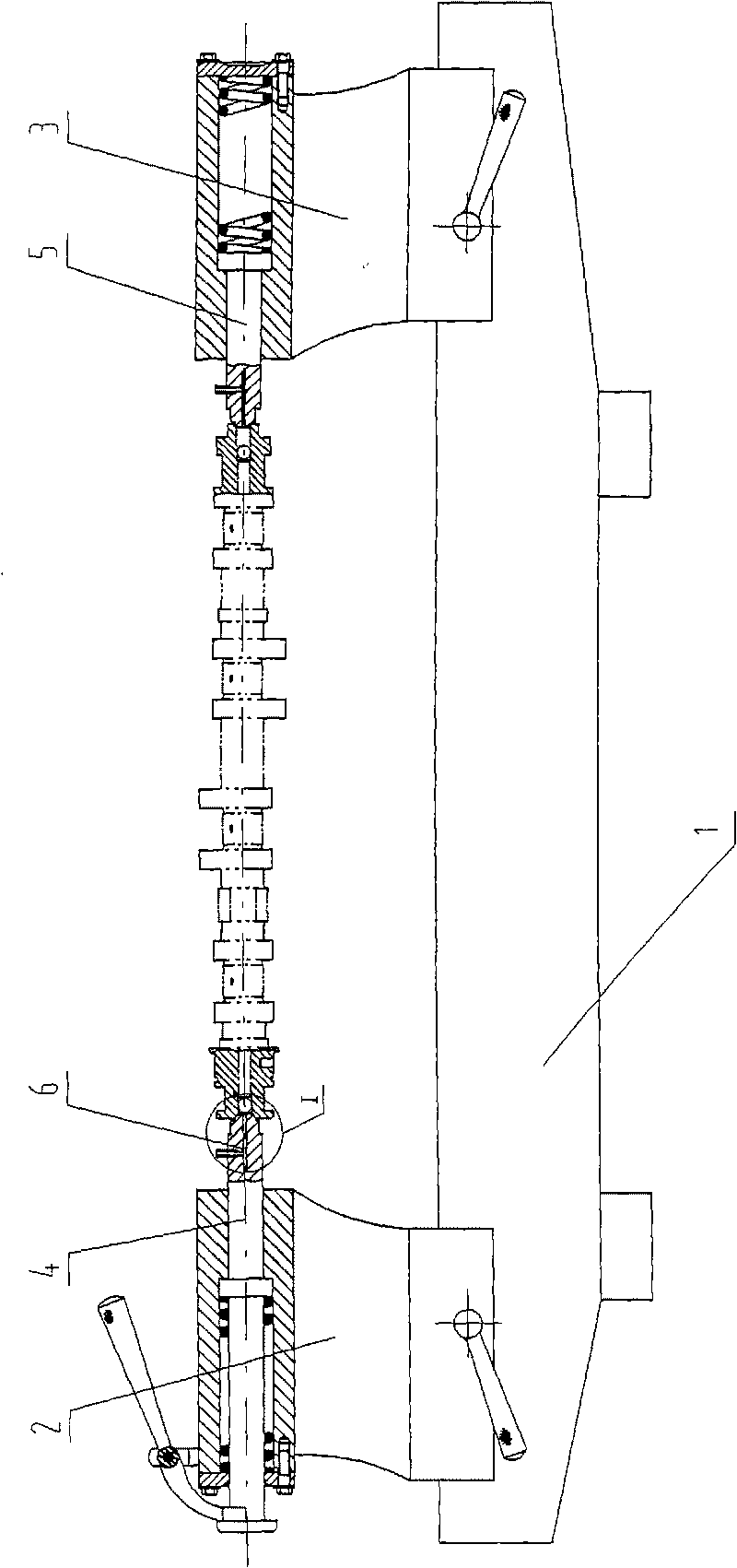

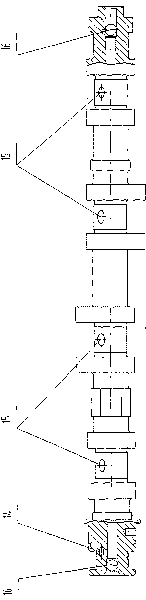

[0020] Examples such as figure 1 , 2 , 4, 5, and 6 show 1. a test bench for engine camshaft oil passage tightness, including a base 1, a front slide 2 and a rear slide 3, wherein the front slide 2 and the rear slide 3 can be Slide horizontally on the base 1, a front push rod 4 is set in the front slide table 2, a rear push rod 5 is set in the rear slide table 3, the shafts of the front push rod 4 and the rear push rod 5 The center line is on the same horizontal straight line, and the front end of at least one of the front ejector rods 4 and rear ejector rods 5 is provided with an air passage 6, and the air inlet of the air passage 6 is arranged on the front end side wall of the ejector rod. The air port is arranged on the end face of the front end of the ejector rod, the shape of the front end of the ejector rod matches the shape of the process hole 13 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com