Lens module

A lens module and coil group technology, applied in installation, optics, instruments, etc., can solve problems such as falling off, magnet 14 cannot be attached tightly, small size, etc., and achieve the effect of simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0119] A preferred embodiment is listed below to illustrate the present invention, but those familiar with the art know that this is only an example, and is not intended to limit the invention itself; function or a lens module with Auto Macro function.

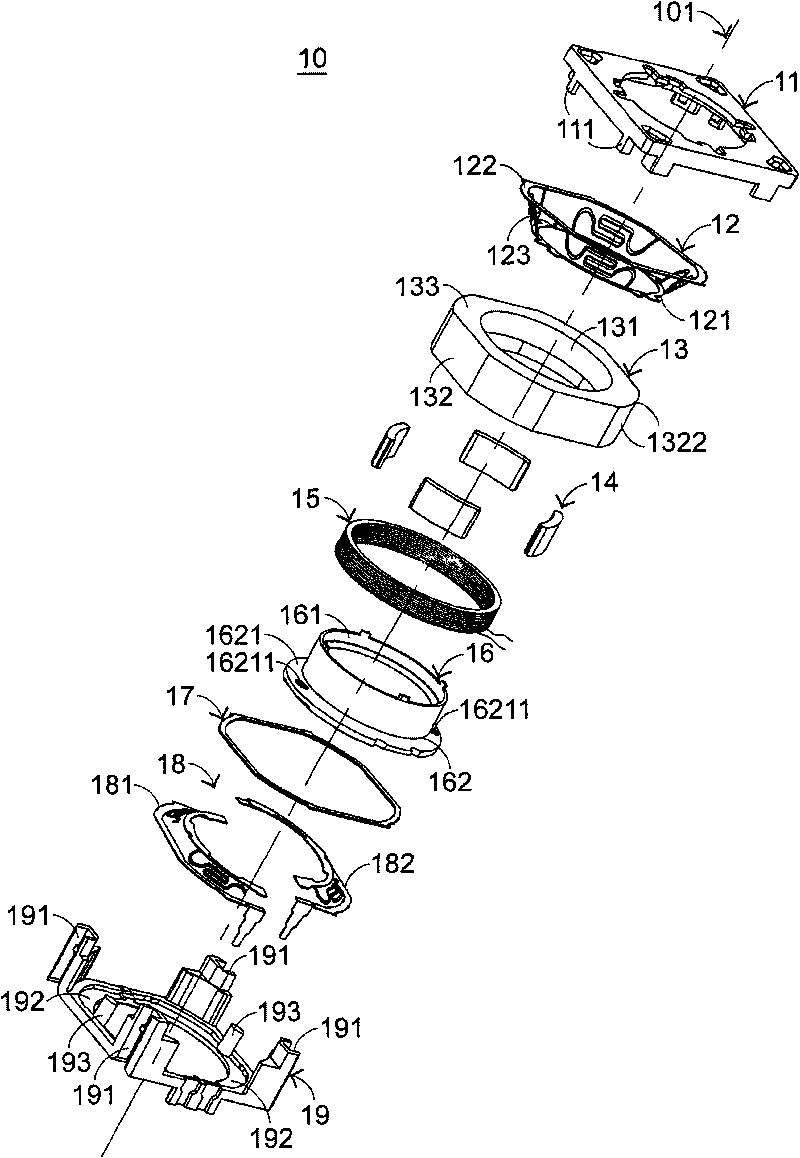

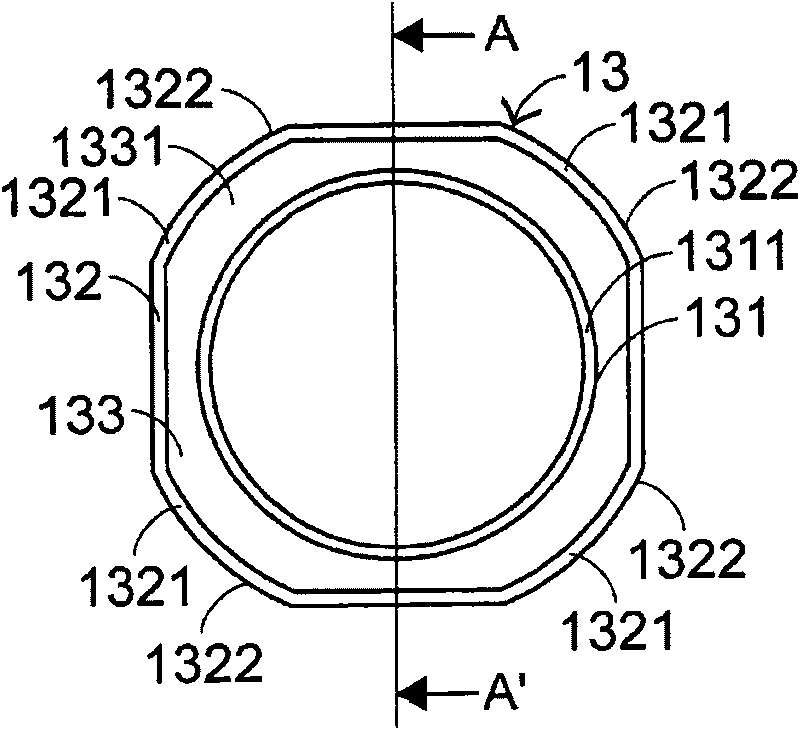

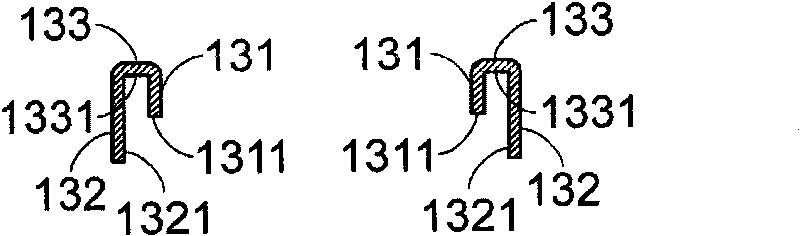

[0120] Please see first Figure 5 , Figure 7A to Figure 7C , Figure 9A , 9B , Figure 10A , 10B ;in, Figure 5 It is an exploded schematic diagram of a better lens module driven and controlled by a voice coil motor in this case; Figure 7A to Figure 7C Shown are the top view schematic diagram and the bottom view schematic diagram of the yoke in the aforementioned preferred embodiment, and the side view schematic diagram along the DD' sectional line; Figure 9A as well as Figure 9B Shown are respectively the bottom view schematic diagram and the side view schematic diagram along the FF' section line of the fixed cylinder in the aforementioned preferred embodiment; Figure 10A as well as Figure 10B Shown are a sche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com