Method for checking trace of circuit layout

A technology of circuit layout and inspection methods, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as time-consuming and errors, and achieve the effect of avoiding tip discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

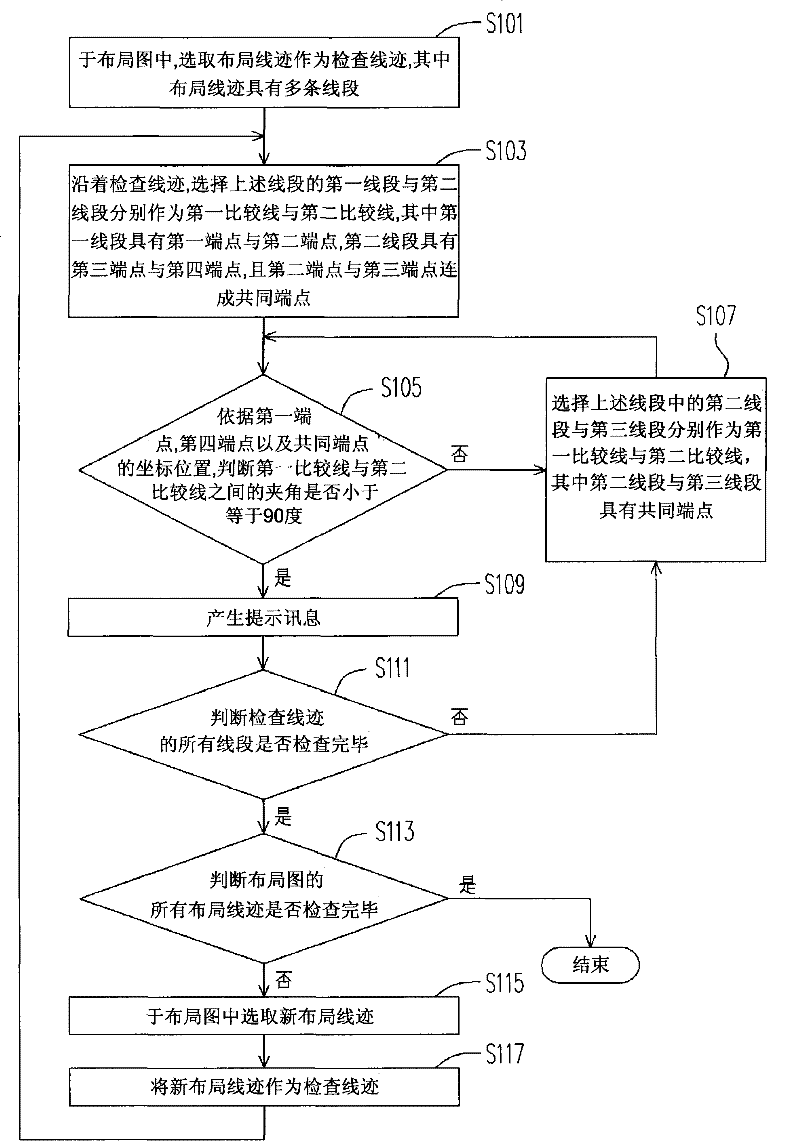

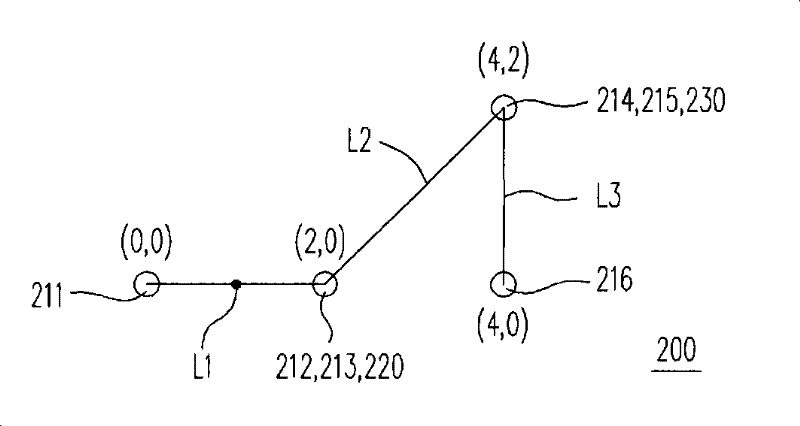

[0024] figure 1 A flow chart of a method for inspecting traces of a circuit layout according to an embodiment of the present invention is shown. figure 2 It is a schematic diagram of layout traces according to an embodiment of the present invention. Please merge reference figure 1 and figure 2 , first, in step S101, select one of the layout traces ( figure 2 Only the layout trace 200 is used as an example). Wherein the layout trace 200 has a plurality of line segments. In this embodiment, the layout trace 200 has, for example, line segments L1 , L2 and L3 , but the scope thereof is not limited. In addition, the above layout diagram may be a layout diagram of a printed circuit board (Printed Circuit Board, PCB).

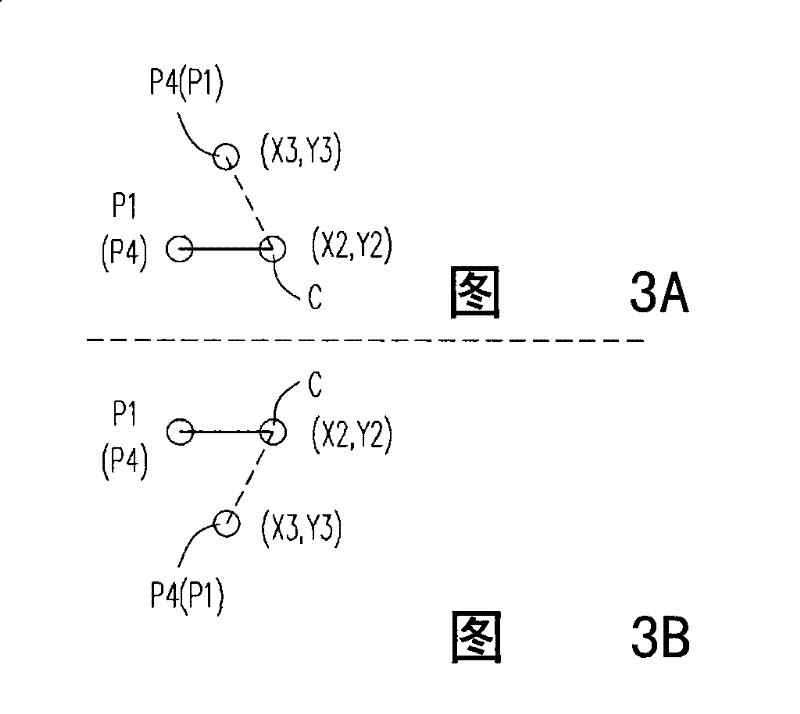

[0025] In step S103, along the layout trace 200, select the first line segment and the second line segment of the above-mentioned line segment as the first comparison line and the second comparison line, wherein the first line segment has a first end point an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com