Core-through split bolt drilling machine of wood formwork system

A technology for pulling bolts and wooden templates, which is applied in the direction of drilling/drilling equipment, portable drilling rigs, metal processing equipment, etc., and can solve problems such as inconvenient construction, easy slipping of nuts, and easy deformation of templates, and achieve labor-intensive solutions. Time-consuming problem, firm connection, simple and practical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

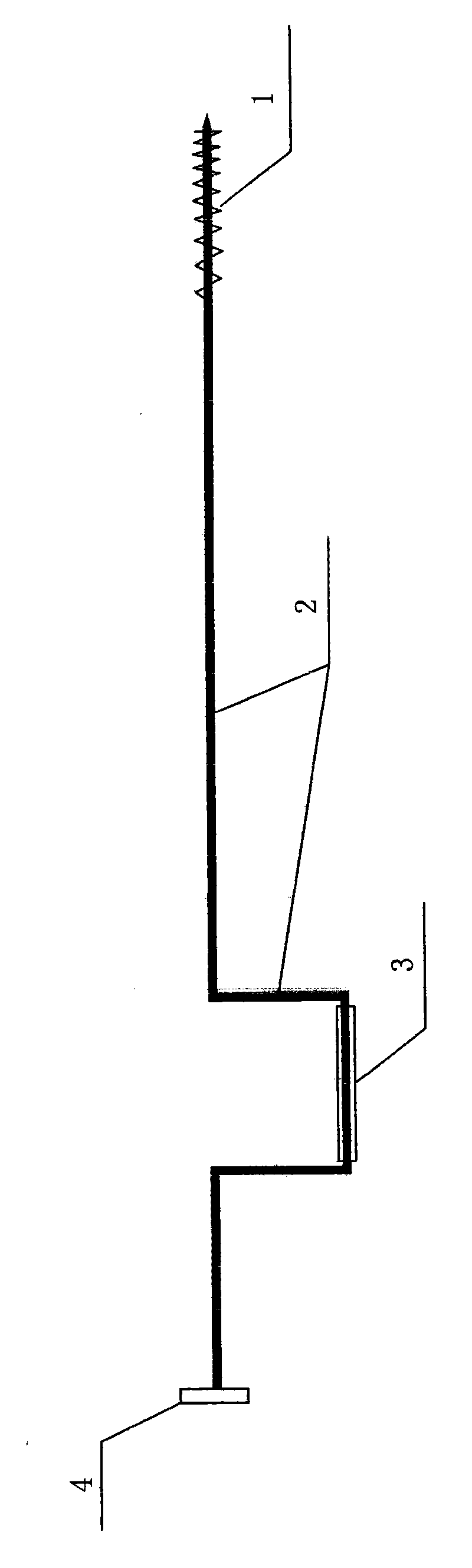

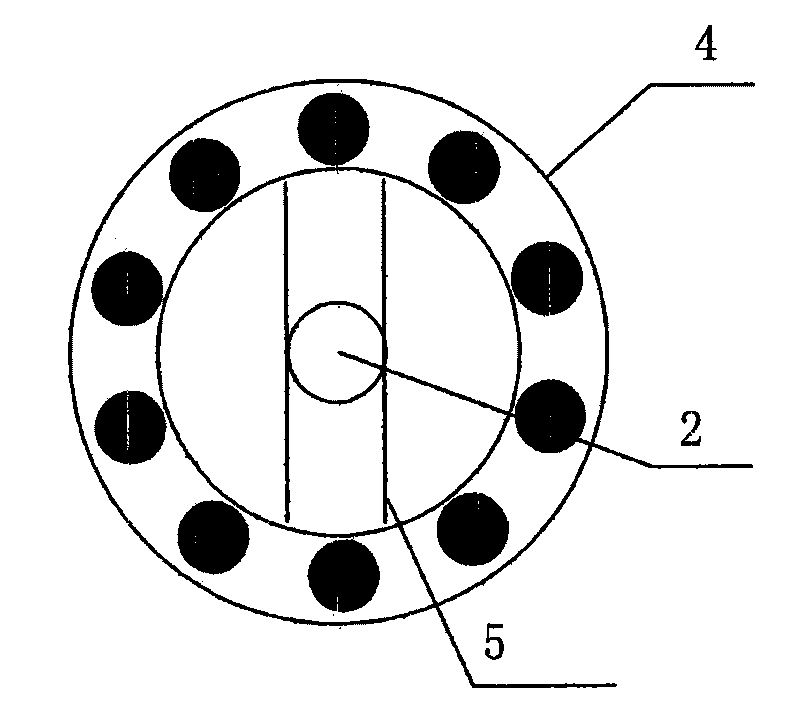

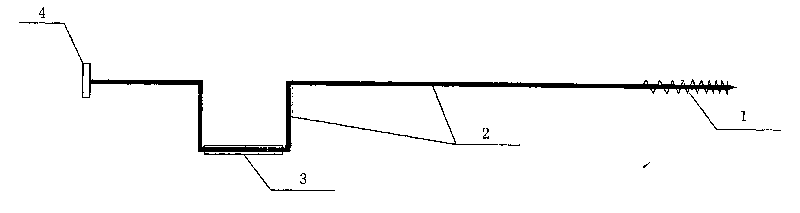

[0016] A kind of wood formwork system core-through pull bolt drill of the present embodiment, such as figure 1 , figure 2 As shown, it includes a twist drill 1, a handle 2, a casing handle 3, and a bearing 4; the handle 2 has a total length of 1450 mm, and one end of the twist drill 1 is welded and installed, and the length of the twist drill 1 is 200 mm. A short steel bar 5 is welded on the inner diameter of the bearing 4, and the short steel bar 5 is welded and fixed to the handle 2; the handle 2 at a distance of 250 mm from the bearing 4 is concave, with a depth of 150 mm and a width of 200 mm; and the lowest point of the concave A casing handle 3 is fitted on the handle 2 of the handle. The twist drill bit (1), the casing handle (3), and the bearing 4 are made of reinforced materials. The handle 2 is made of a circular steel bar material with a diameter of 10-14mm.

[0017] When in use, stretch the thread on one side of the formwork, mark out the hole position, and dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com