Hydraulic sliding type watertight door for ship

A sliding, watertight door technology, applied in the field of watertight doors, can solve the problems of few functions, difficult to meet the needs of watertightness, no fire resistance, etc., and achieve the effect of multiple functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

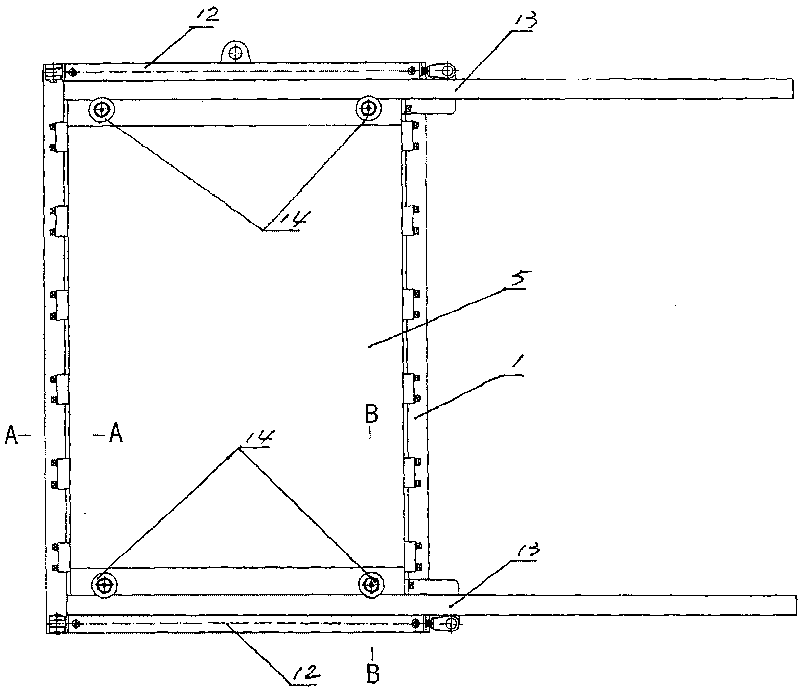

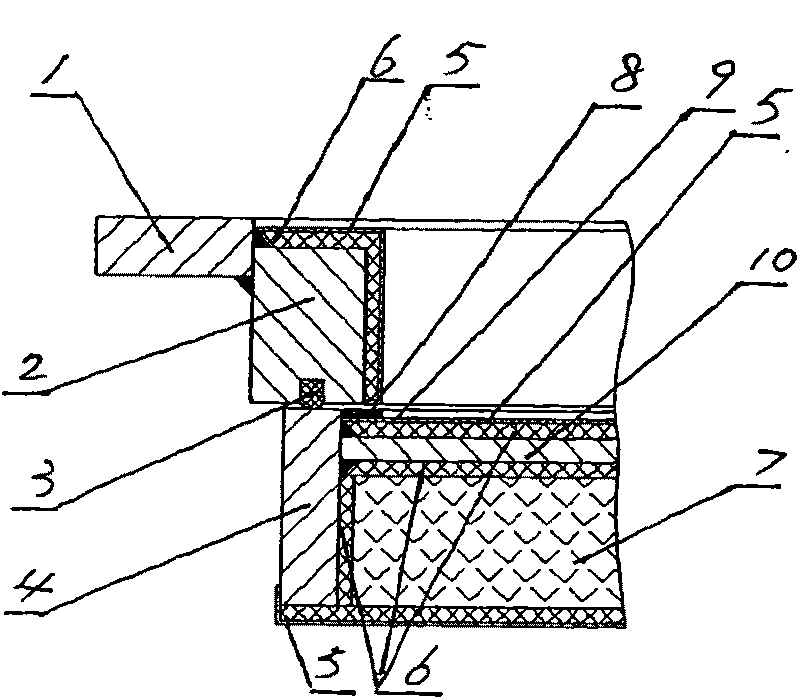

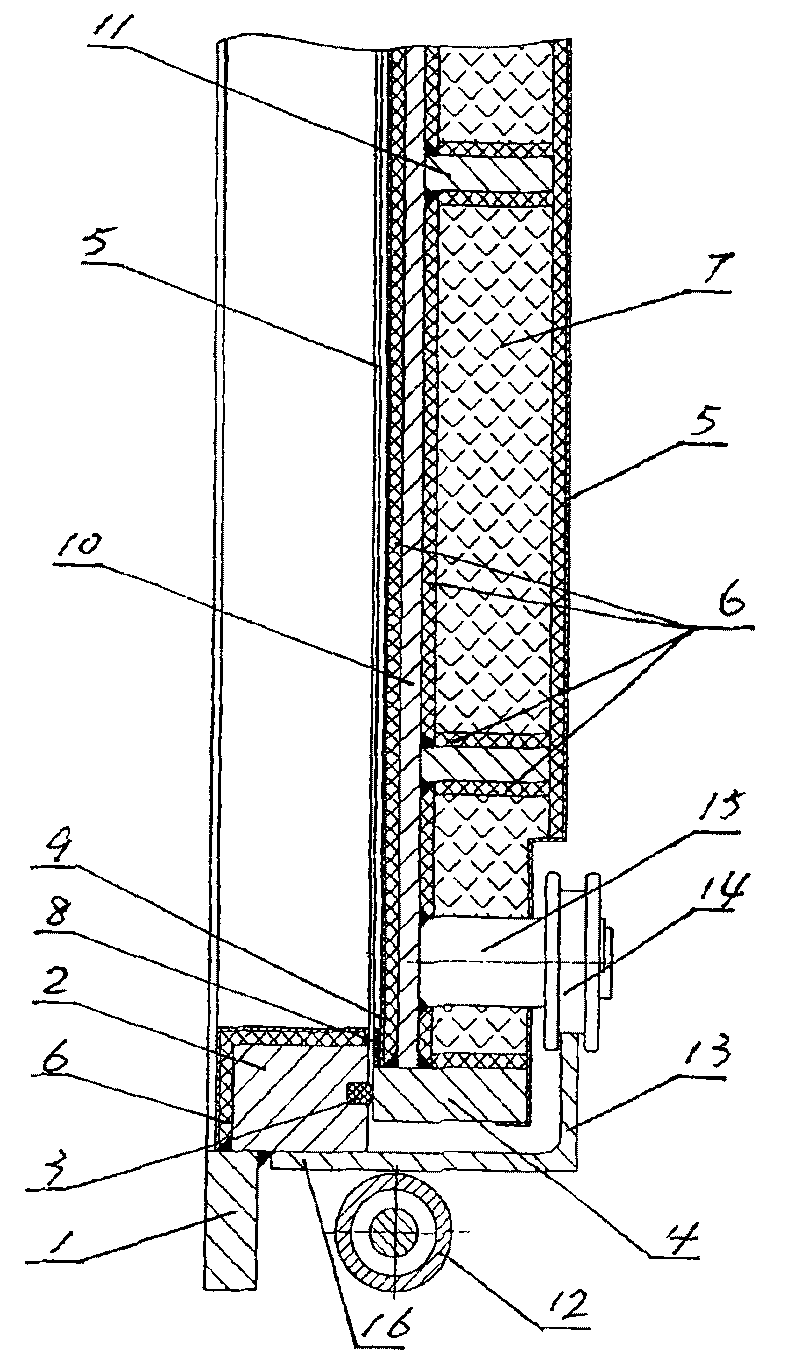

[0015] Such as figure 1 , figure 2 and image 3 As shown, the marine hydraulic sliding watertight door of the present invention includes a door frame and a door leaf, the door frame includes a main door frame 2, and an auxiliary door frame 1 is arranged around the main door frame 2, and the main door frame 2 and the auxiliary door frame 1 are sealed by welding. connected. The door leaf is inside the main door frame 2 . The door leaf wherein comprises frame 4, and frame 4 is provided with door panel 10, and the periphery of door panel 10 and frame 4 are welded together in sealing shape. On the opposite side of the main door frame 2 and the frame 4, a circumferential groove is processed, and a sealing strip 3 is embedded in the circumferential groove, so that between the main door frame 2 and the frame 4 in the closed state, that is, between the door frame and the door leaf, there is a sealing fit.

[0016] The top and the bottom of main door frame 2 are all provided with g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com