Pulley-type hoisting connecting piece

A technology for connecting parts and pulleys, applied in the direction of transmission elements or pulley ropes or cables, belts/chains/gears, textile cables, etc. Small stress, increased bending radius, safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

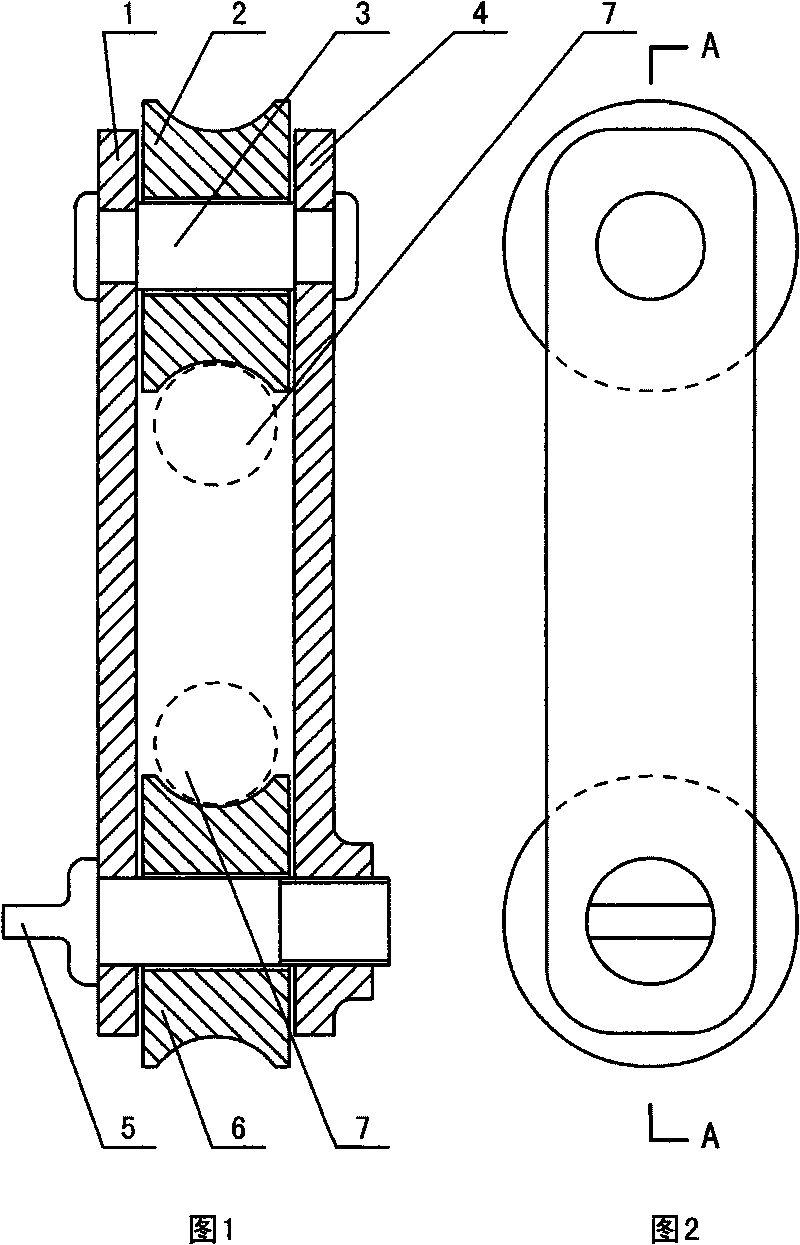

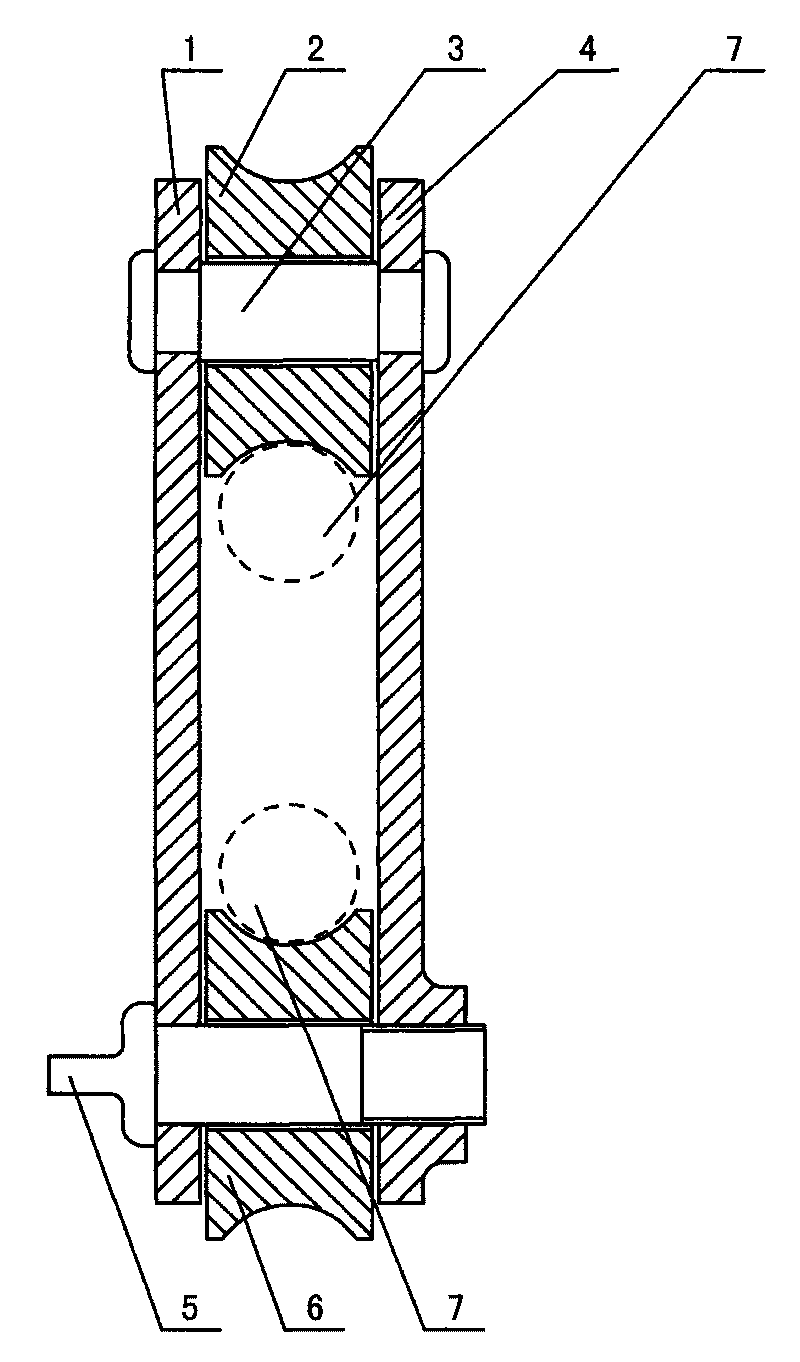

[0010] Embodiments of the present invention will now be described in detail in conjunction with the accompanying drawings.

[0011] In order to work stably and reliably, the upper pulley center sheath 2, the shaft 3 and the lower pulley center sheath 6 are all made of high-quality 45# steel, and heat treatment must be carried out after machining. The function of the shaft 3 is to carry the upper pulley The central sheath 2, the function of the upper sheave central sheath 2 is to ensure that the steel wire rope 7 is always in the center position, the function of the bolt rod 5 is to carry the lower sheave central sheath 6, and the function of the lower sheave central sheath 6 is to ensure that the steel wire rope 7 Always in the central position, the left guard plate 1 and the right guard plate 4 are made of stainless steel.

[0012] In summary, the present invention is convenient and stable to use, safe and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com