Side-mounted suspended magnetic induction liquid level switch

A liquid level switch and magnetic induction technology, applied in the field of magnetic induction liquid level switches, can solve the problems of large volume, poor detection reliability and complex structure of the liquid level switch, and achieve the effects of simple structure, simple installation and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

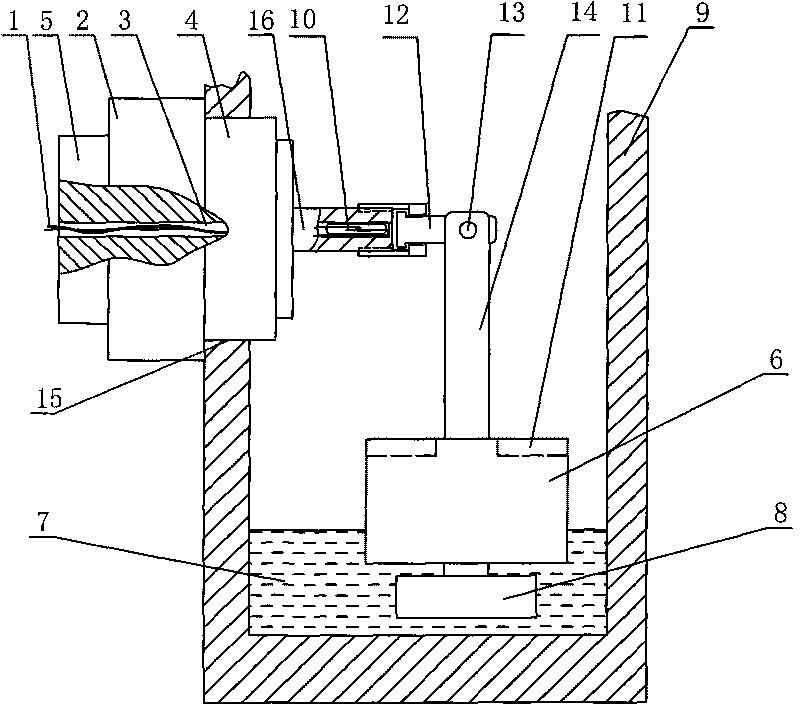

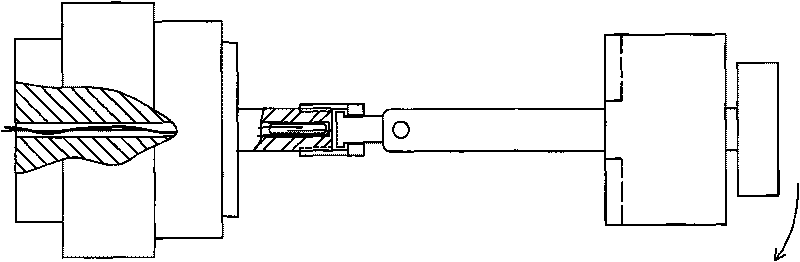

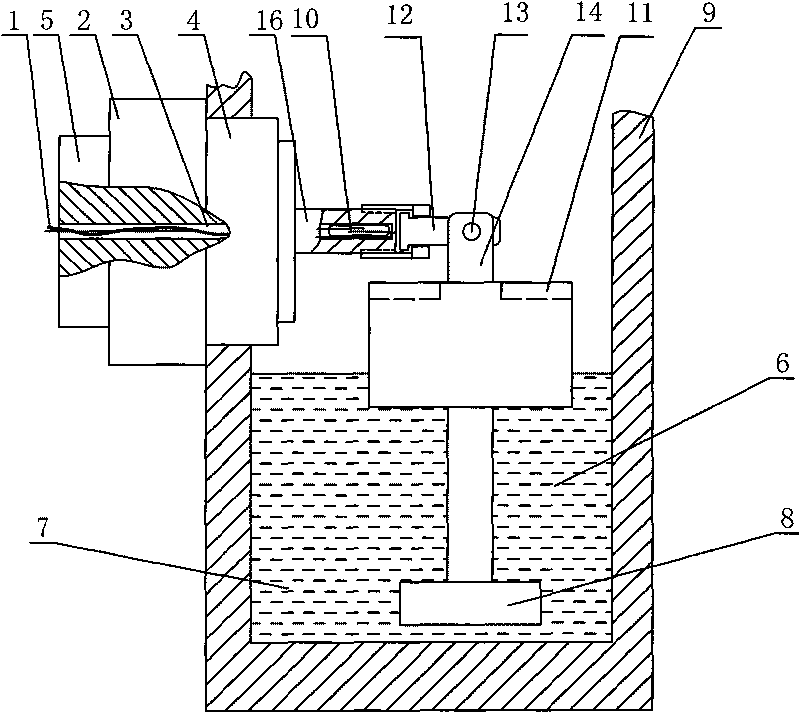

[0033] For the first structure of the side-mounted pendant magnetic induction liquid level switch of the present invention, see figure 1 , figure 2 with image 3 , including transition pieces, threaded joints, non-magnetic stainless steel tubes, dry reed switches, output leads, horizontal shafts, non-magnetic stainless steel rods, floats and weights; the transition piece is a cylindrical structure with internal threaded holes, which is welded in the box The outside of the through hole on the side of the body; the threaded connector is an externally threaded cylindrical structure with a central through hole, which is threaded with the transition piece; the stainless steel tube is welded coaxially with the center of the inner end of the threaded connector; the reed switch is set on a stainless steel The inner end of the tube is used to output the on-off signal, and the output lead wire is connected to it; the other end of the output lead wire passes through the central through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com