Cable pulling tool

A tool and cable end technology, applied in the direction of cable laying equipment, etc., can solve the problems of injury to construction personnel, cable damage, delay in construction, etc., and achieve the effect of improving safety factor and efficiency, increasing traction strength, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Example 1 、Cable pulling tool suitable for YJV-8.7 / 10kV 3*240

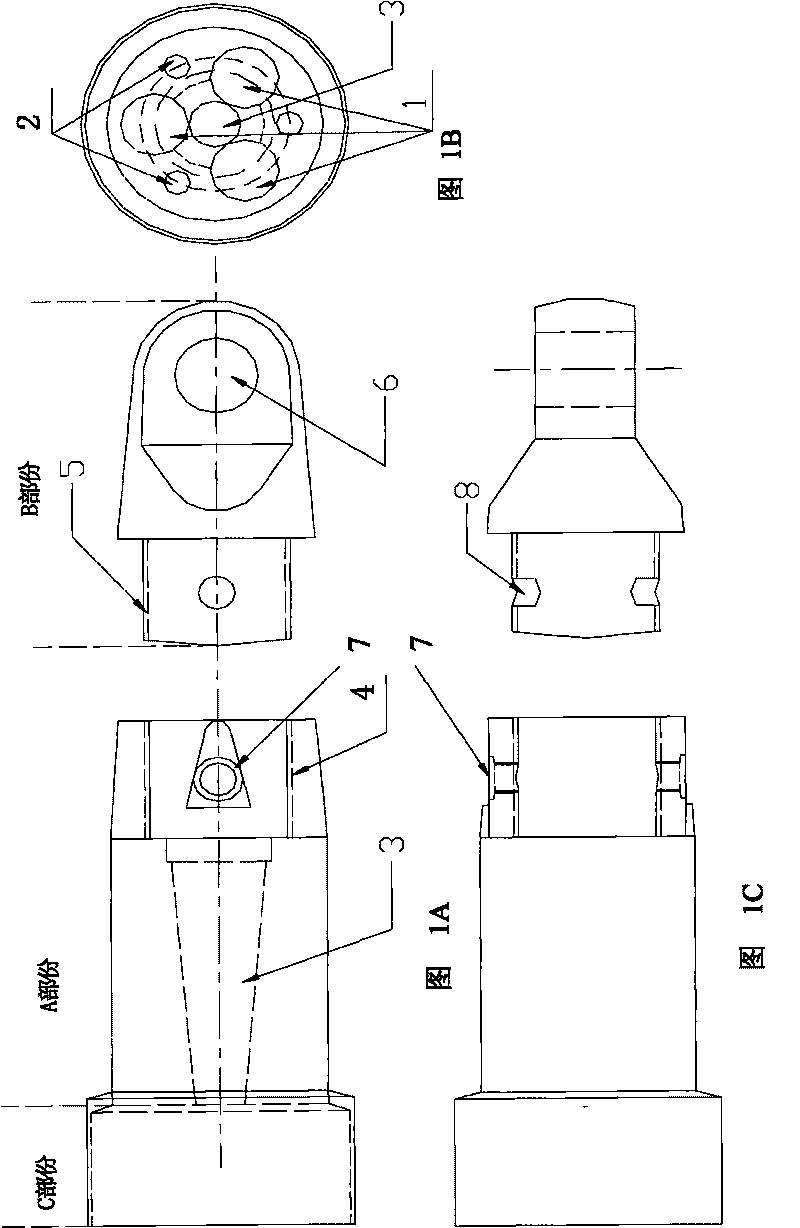

[0014] The structure of the cable pulling tool suitable for YJV-8.7 / 10kV 3*240, such as figure 1 As shown, it is mainly divided into three parts, namely the conductor expansion part A, the traction connection part B and the cable end protection part C, as follows:

[0015] Conductor expansion part A has a length of 140mm. According to the design expansion strength requirements, the outer diameter of part A is 72mm. The longitudinal direction of part A is uniformly arranged with three wire holes with an outer diameter of 18.4mm and a depth of 90mm. 1 (The center distance of the wire holes is set to 31.0mm according to the center distance of the insulated cores in the cable). There are three small round holes 2 with a diameter of 12mm and a depth of 90mm that are conducive to expansion joints distributed between the wire holes 1. The radius of the small end is 8.5mm (slightly smaller than the radius of the...

Embodiment 2

[0018] Embodiment 2, the use of cable pulling tools suitable for YJV-8.7 / 10kV 3*240

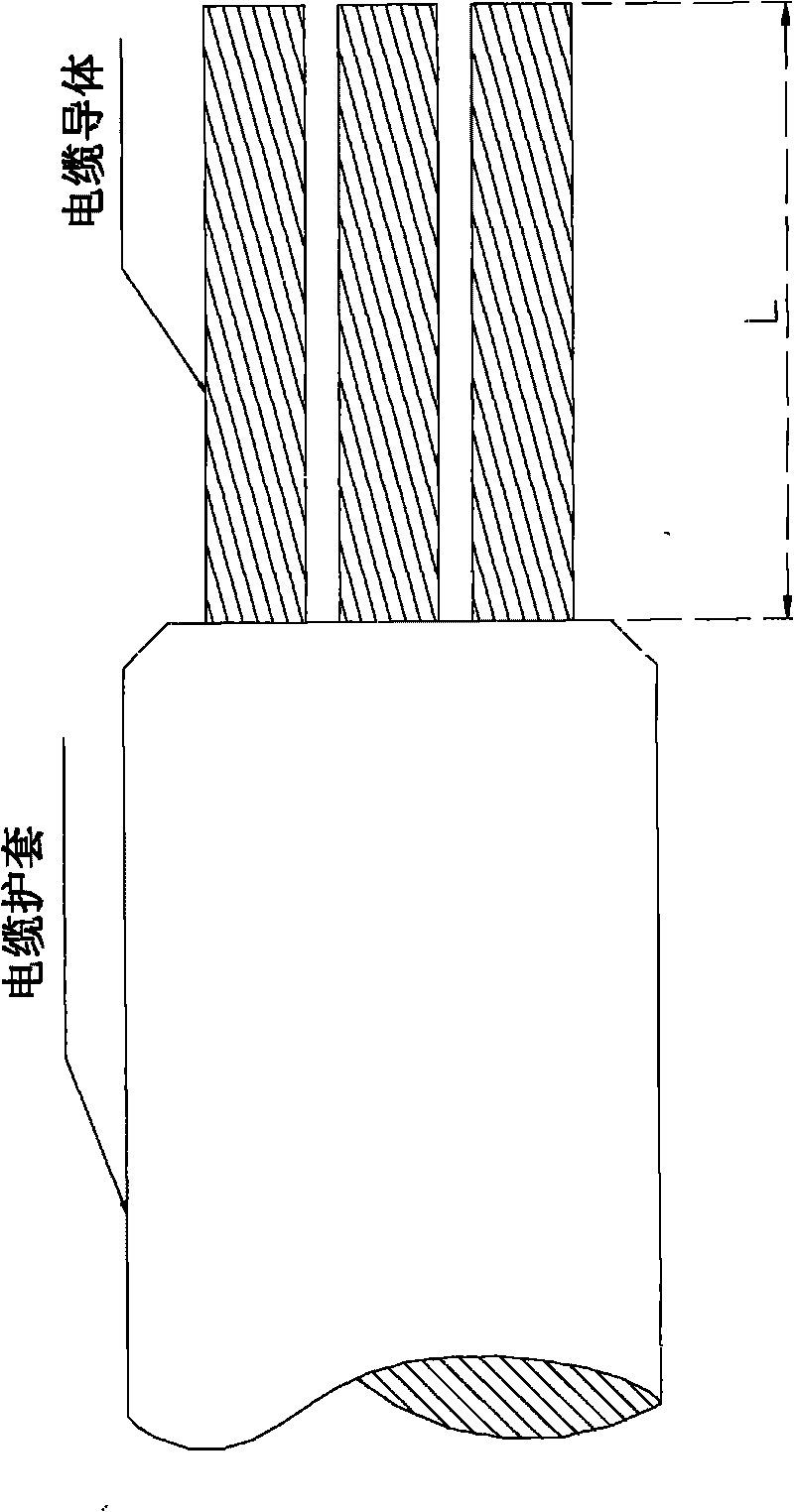

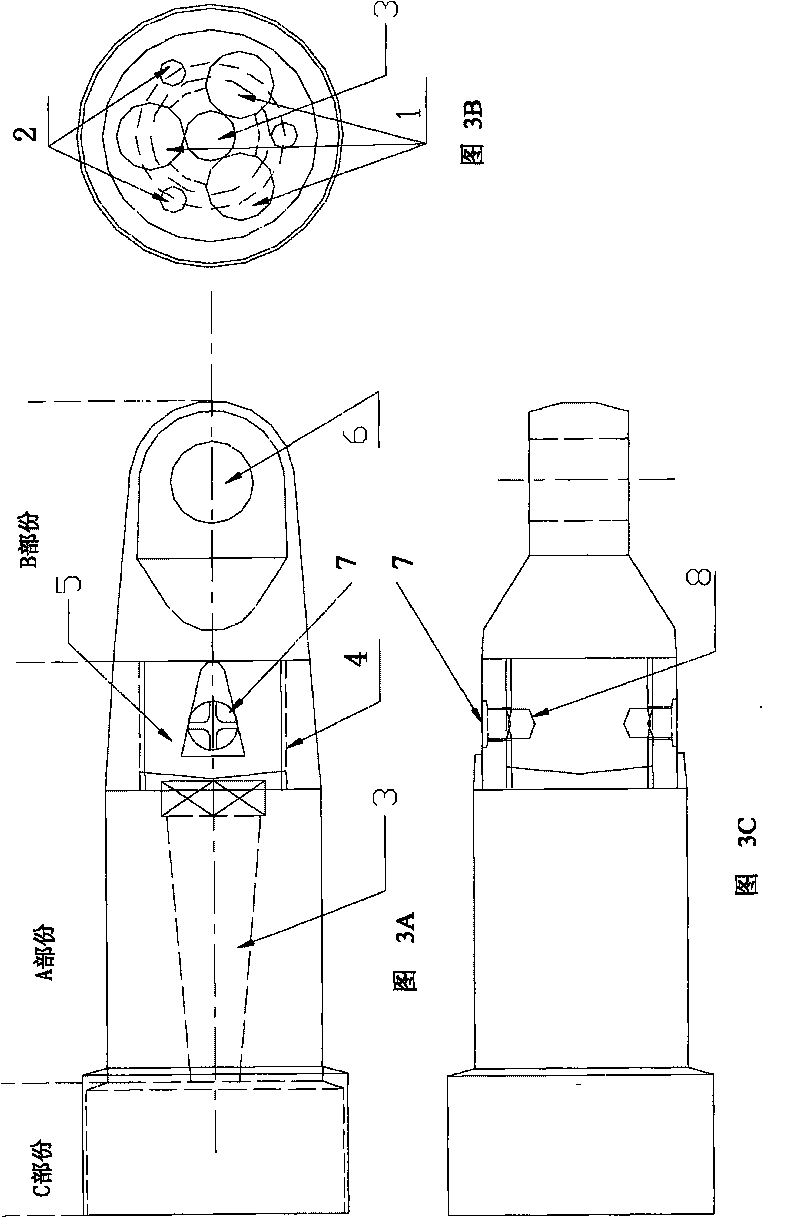

[0019] When in use, the outer diameter of the three-core cable whose outer diameter is slightly smaller than the inner diameter of the protective cover part C is as attached figure 2 Remove the material outside the conductor, the length L of the exposed part of the conductor in the figure is less than the attached figure 1 The depth of the middle wire hole 1 is 2~5mm. Insert the three core conductors into the wire hole 1 completely, and use the expansion screw to screw the expansion screw between the three conductors from the 4th end of the inner thread of part A to expand the conductor traction tool together, and then pass Thread to connect part A and part B, and then use countersunk screws to reinforce the connection between A and B through symmetrical countersunk screw holes 7 and light holes 8 (see the attached diagram for the combination diagram) image 3 ); the cable can be directly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com