Oyster cleaning device

A cleaning device and technology for oysters, applied in bivalve processing and other directions, can solve the problems of low production efficiency, low production efficiency, low level of processing mechanization, etc., so as to improve the production efficiency of enterprises, reduce processing costs, improve product quality and improve product quality. The effect of product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Referring to the accompanying drawings, an embodiment of an oyster cleaning device of the present invention will be described in detail subsequently.

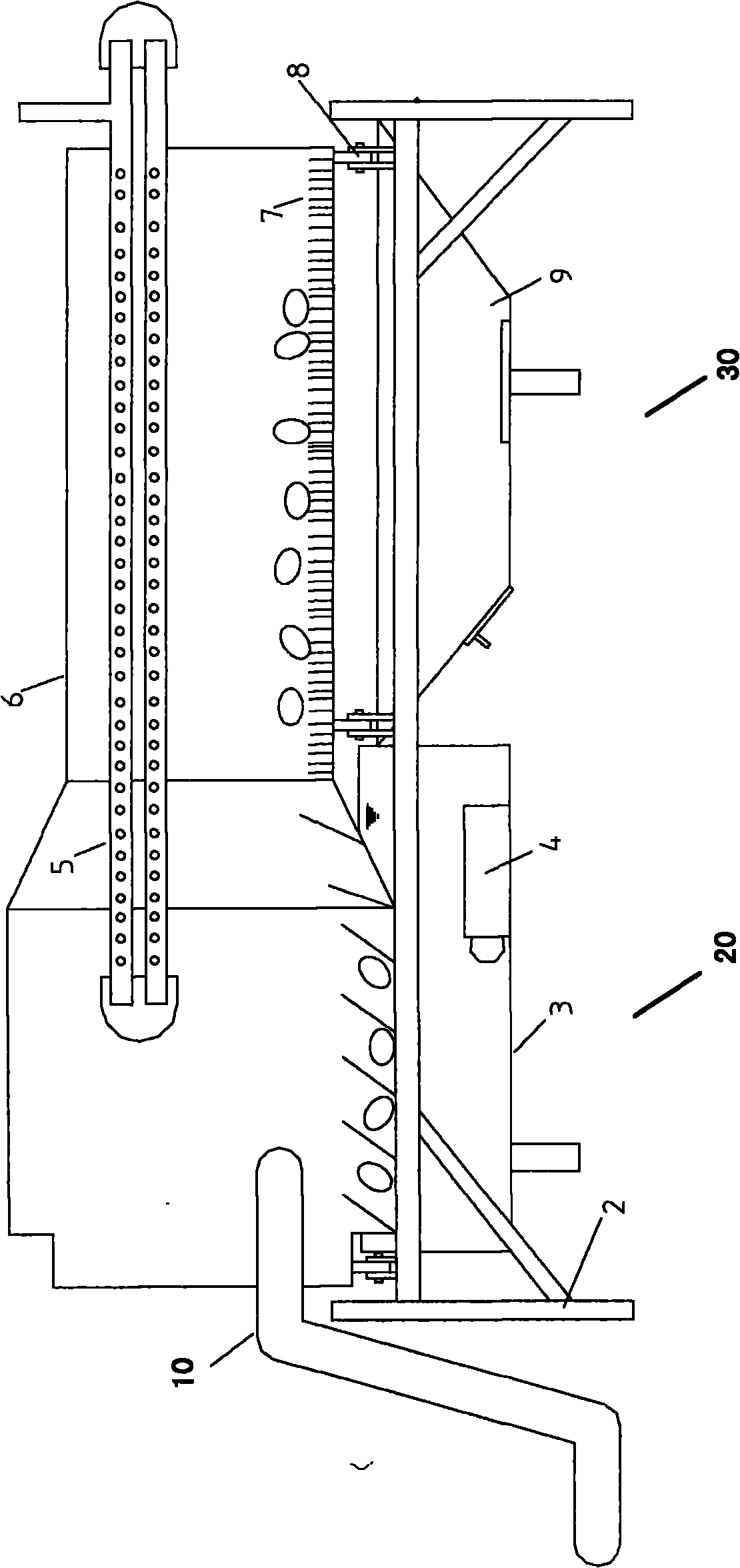

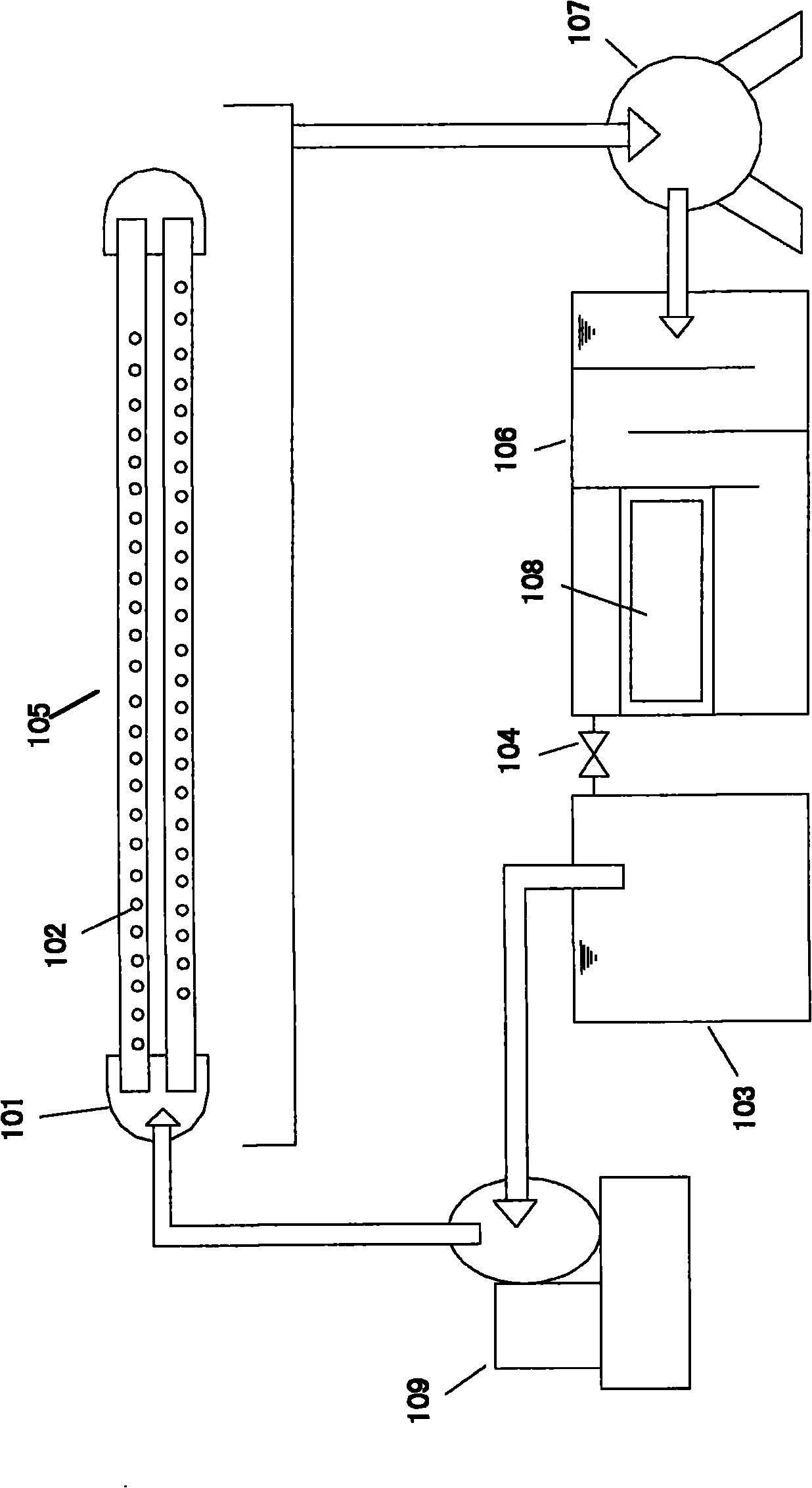

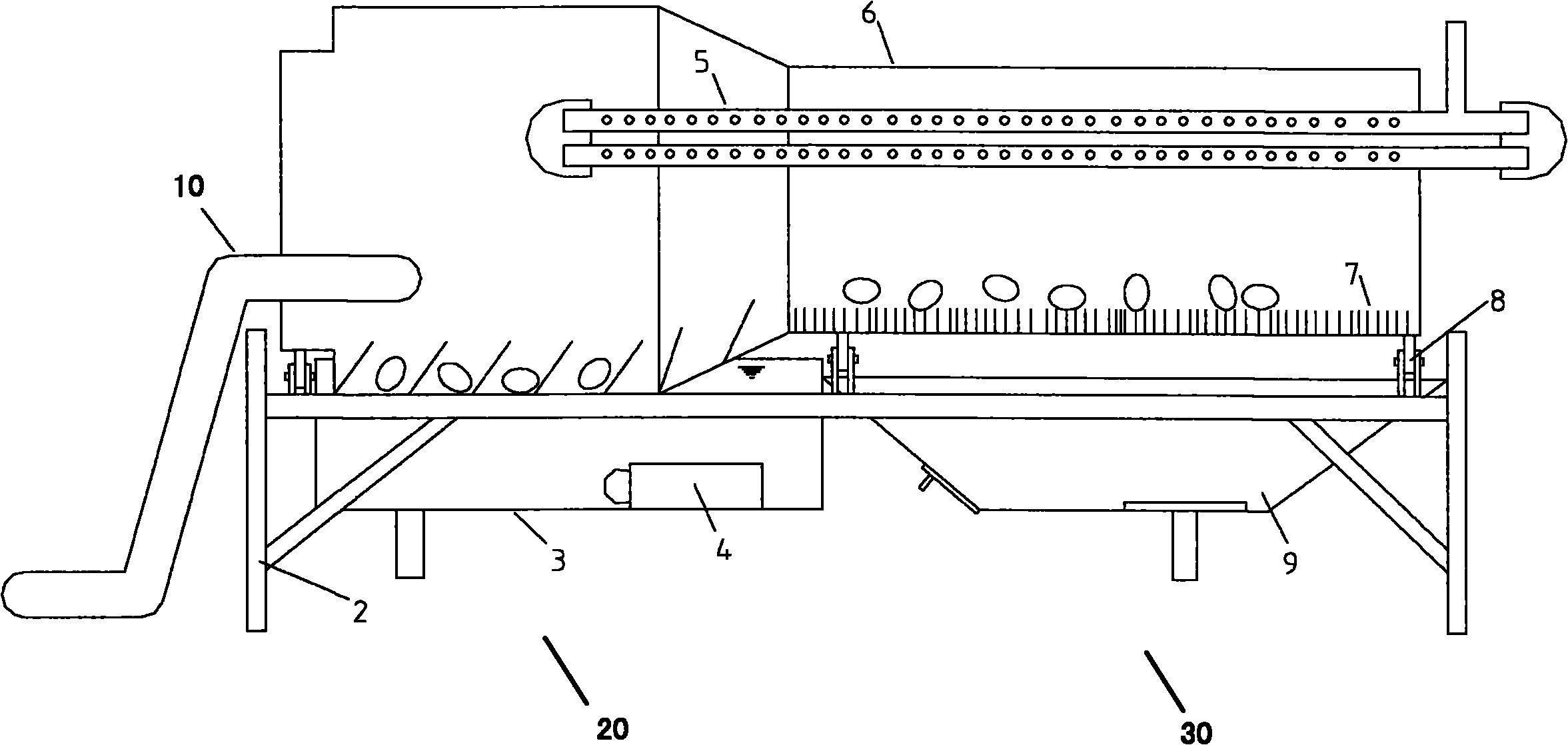

[0020] Reference attached figure 1 , The oyster cleaning device as an embodiment of the present invention includes: a feeding mechanism 10, a pre-cleaning mechanism 20 and a spray cleaning mechanism 30. Wherein, the outlet end of the feeding mechanism 10 is connected to the inlet end of the pre-cleaning mechanism 20 , and the pre-cleaning mechanism 20 includes the dipping tank 3 , the ultrasonic generator 4 and the front section of the cleaning net cylinder 6 . The spray cleaning mechanism 30 is composed of the rear section of the cleaning net cylinder 6, the high-pressure spray system 5, and the sump 9. The above-mentioned cleaning net cylinder 6 is fixed on a frame 2. The following are introduced respectively:

[0021] in the attached figure 1 Among them, the cleaning net cylinder 6 is the main working part of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com